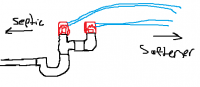

So I'm just an average DIYer so treat me like an idiot. My water softener and sulfur machine both discharge vertically, run along the wall in a 5/8 (inside diameter) pipe and then tie into an 1 1/2" pipe. Sulfur remover is extremely loud when it goes off but I'm more worried about the discharge running back into the tanks.

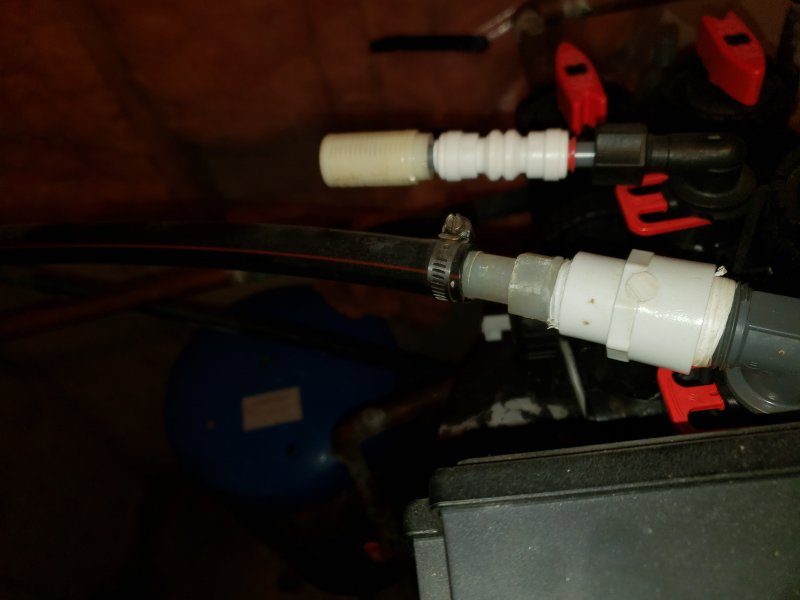

I'm installing a new water softener since the other one never worked since I bought the place. Even if the water got pumped up into the line, wouldn't at least a small portion of it flow back into the softener/sulfur tanks? Where they tie in, there that ABS pipe terminates just outside of the pic. Should I add a 1 1/2" check valve (with spring) after the two connect to the plumbing? OR should I add check valves on each hose, right off of the softener and sulfur tank if I can.

Water softener is a Whirlpool WHES33 and sulfur i'm not sure.

Thanks guys!

Dave

I'm installing a new water softener since the other one never worked since I bought the place. Even if the water got pumped up into the line, wouldn't at least a small portion of it flow back into the softener/sulfur tanks? Where they tie in, there that ABS pipe terminates just outside of the pic. Should I add a 1 1/2" check valve (with spring) after the two connect to the plumbing? OR should I add check valves on each hose, right off of the softener and sulfur tank if I can.

Water softener is a Whirlpool WHES33 and sulfur i'm not sure.

Thanks guys!

Dave