The listed

99% outside design temp for the airport in Lethridge is -16F/-27C. A code minimum indoor design temp is 20C, so you're looking at a interior to exterior temperature delta of 47C.

HVAC contractors rarely use Manual-J methods, and even when they do they use ultra-conservative assumptions about air leakage and the quality/level of the insulation or using unrealistic indoor & outdoor design temperatures, which usually ends up oversizing the calculated level by ~1.3- 1.5x . They then multiply that by some other factor "just in case", often oversizing the equipment by 2x sometimes more, which is bad for both comfort & efficiency. That way they reliably avoid the 5AM call on the coldest night of the year from the shivering irate customer, but they're not really doing you a favor by oversizing (especially if you have it broken up into zones.)

Professional engineers and energy nerds run more aggressive numbers and are more likely to hit it right.

Rules of thumb are really crude and fraught with error but a decently tight 2x6 wall construction with code-min windows typically comes in at about 15 BTU/hr per square foot at -20C (a 40C delta) for the above grade portion, with neglible additional load for an insulated below grade basement. At a 47C delta that would extend to about (47/40) x 15 = ~18 BTU/hr per square foot, call it 20 BTU/ft due due to the 12' ceilings in part of the house (taller windows too?) so for a 2030' house you're looking at a likely design load in the 40,000 BTU/hr range, at most 50,000 BTU/hr (unless it's a walk-out basement with a lot of exposure.

ASHRAE's recommended or oversizing factor as the optimal compromise for comfort/efficiency is 1.4x so upsizing from 40K would put you in the 55,000 BTU/hr range.

With a ~40K-50K heat load the UFT-080W has plenty of burner to spare for running an indirect hot water heater as a separate zone. This will probably be substantially cheaper than a separate Phoenix Light Duty, or a pair of them. (The Westinghouse version runs

less than USD$1700 from

multiple online vendors. A 40-50 gallon indirect hot water heater would be under $1500. ) Operating the indirect as "priority zone" suppressing heating zone calls when the tank is calling for heat guarantees excellent HW performance, and the tank temp recovers quickly (2x as fast as traditional standalone tanks), well before the house begins to cool off.

A heat recovery ventilator (HRV) with a recirculation mode can filter air 24/365 running continuously at very modest air volumes. In your climate it's better to build the house super-tight and run active ventilation, and lower the ventilation rate in winter if it gets too dry rather than running a humidifier. Humidifiers often increase the mold spore counts, and amplify the rot-risk/mold hazards of any leaks in your vapor barrier. If you run a humidifier, keep it under 35% relative humidity in winter. In an air tight house you can usually control the humidity by dialing back the ventilation rate if it gets too dry. This works pretty well for folks who don't create a lot indoor air pollution, but people who smoke, use lots of aerosol sprays, or cleansers with volatile human hazard components shouldn't back off the ventilation rates that much.

Something like a middle of the road Venmar HRV with recirculation mode is on the order of USD$1200-1500, and the installed cost in my area would be USD$2500-3000 if done in new construction. The ducts are tiny compared to what's usually used for AC or heat. (6" hard piped trunks, 4" branches.)

By divorcing the ventilation function from the heating or cooling function you have complete control over the ventilation rates, since the duty cycle isn't dependent upon having a heating or cooling load, and you can crank it up for periods when it might be needed (say, when roasting a goat in an open charcoal barbeque in the middle of the family room or something.

), and dialing it up or down to whatever feels comfortable the rest of the time.

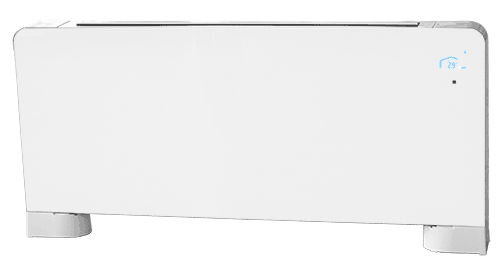

If radiators are out, would microzoning using

thin profile hydronic wall coils be acceptable to the boss? (That would work with either a hot water heater or a low-modulating boiler like the UFT-080W.) The advantage of local wall coils is that they don't drive outdoor air infiltration, or spread indoor air pollution to other parts of the house. And, by micro-zoning it's dead-easy to tweak the room-to- room temperature balance.

Unless you're building the lousiest least insulated house in AB or have a huge amount of west facing window, your cooling load will come in under 2 tons for a house that size. There are multi-zone mini-splits that might cover that (and most of your heating load too), but I'd be reluctant to use mini-splits as the primary heat source in a location that regularly sees -35C unless it's a high-performance house, well beyond code. But cooling is a different animal. Point source cooling with 1-3 wall coil type mini-splits (no ducts) usually works just fine in 2000' houses. A 2 or 2.5 ton multi-split will typically support up to three zones on one compressor, and you can put the coolth exactly where it's needed most. Multi-splits are as a rule heat pumps too, and during milder weather (down to -10C to -15C or so) something like a

Mitsubishi MXZ-3C30NAHZ would have sufficient capacity to run at very high efficiency, giving you some options, even though it doesn't have enough low-temp capacity fully to cover your heating load at -27C. (A mini-duct cassette can serve 2-4 nearby doored off rooms, if need be.)

As with heating, a room-by-room cooling load calculation by a competent third party (not an HVAC contractor) would be in order before fully specifying the equipment.