Hi Plumbing Experts,

I'm brand new to this forum and I know nothing about plumbing. I installed a 7 stage RO system under my sink early last year and never really got the system to meet my expectations. The last part of the system I'm trying to fix is the operating volume. Please if you know how to reduce the noise of an under-sink RO system, help me out...

Description of Problem: very loud sound & vibration (like a "water hammer?") when the Brine-Out Line begins draining from the Permeate Pump. This is not a new occurrence, it has happened for the entire lifetime of the system. I'm hoping to find a way to reduce the volume of the sound.

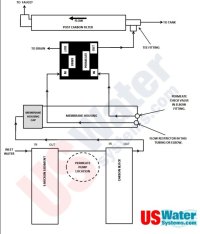

It's a very simple system, as you can see in the attached diagram, the Permeate Pump is an ERP 500 and I've got a 35 GPD membrane. The filters and everything are in good condition, they're relatively new. The hoses/lines are all ez-fit and there are no leaks. I have bled the system multiple times to ensure there is no air trapped inside. I recently input a flow regulator on the inlet line to the system, reducing the pressure to 60 PSI. This was a good decision, because it helped remove tiny bubbles from faucet water. It helped reduce the "water hammer" before the tank gets fully pressurized; but when the tank is near full, jeez the permeate pump is noisy.

So far, I've considered adding a pressure regulator on the brine-out line and/or foam pipe insulation. What are your thoughts?

I'm brand new to this forum and I know nothing about plumbing. I installed a 7 stage RO system under my sink early last year and never really got the system to meet my expectations. The last part of the system I'm trying to fix is the operating volume. Please if you know how to reduce the noise of an under-sink RO system, help me out...

Description of Problem: very loud sound & vibration (like a "water hammer?") when the Brine-Out Line begins draining from the Permeate Pump. This is not a new occurrence, it has happened for the entire lifetime of the system. I'm hoping to find a way to reduce the volume of the sound.

It's a very simple system, as you can see in the attached diagram, the Permeate Pump is an ERP 500 and I've got a 35 GPD membrane. The filters and everything are in good condition, they're relatively new. The hoses/lines are all ez-fit and there are no leaks. I have bled the system multiple times to ensure there is no air trapped inside. I recently input a flow regulator on the inlet line to the system, reducing the pressure to 60 PSI. This was a good decision, because it helped remove tiny bubbles from faucet water. It helped reduce the "water hammer" before the tank gets fully pressurized; but when the tank is near full, jeez the permeate pump is noisy.

So far, I've considered adding a pressure regulator on the brine-out line and/or foam pipe insulation. What are your thoughts?