AndyB7

New Member

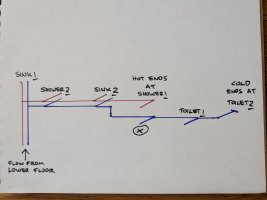

I'm trying to solder a copper/pex adapter for "Shower 1" on the cold pipe at (X) and despite doing several other joints successfully, this one just won't take. I suspect residual water is the culprit but on my last (second) attempt I was confident I had dried everything out by a combination of blowing and sucking from various points. The solder joint had capillary action and seemed solid when cooled (I couldn't twist it off) but alas, it did not stand up to water pressure.

1) Firstly, does my description of the failed joint sound like it was caused by water or would it have not even passed the stress test? (It's possible I burned off the flux on this one and I had actually got the water out ok after all. I got dark smoke before the solder would melt - is that the flux failing?

2) To make sure on my next attempt, how would you approach draining/drying this part of the system (i.e. what valves open/closed and blow/suck from which points). I don't want the expense of a JetSwet for just one joint and I really don't like/trust the idea of stuffing bread in there if avoidable.

In the diagram, fittings numbered "1" are in the bathroom I'm working on, and those numbered "2" are in the adjoining bathroom. There is no other water piping on this floor.

The shut off for Toilet 1 is seized open so I'd rather not muscle that and add to my problems right now.

Re: technique, I am a rank amateur but have learned the basics from instruction: Clean thoroughly until shiny, don't handle, flux x 2, heat fitting only, test for readiness with solder tip, clean up afterwards).

Profound thanks in advance. I feel I may have bit off a bit more than I can chew but I'm too close to quit.

1) Firstly, does my description of the failed joint sound like it was caused by water or would it have not even passed the stress test? (It's possible I burned off the flux on this one and I had actually got the water out ok after all. I got dark smoke before the solder would melt - is that the flux failing?

2) To make sure on my next attempt, how would you approach draining/drying this part of the system (i.e. what valves open/closed and blow/suck from which points). I don't want the expense of a JetSwet for just one joint and I really don't like/trust the idea of stuffing bread in there if avoidable.

In the diagram, fittings numbered "1" are in the bathroom I'm working on, and those numbered "2" are in the adjoining bathroom. There is no other water piping on this floor.

The shut off for Toilet 1 is seized open so I'd rather not muscle that and add to my problems right now.

Re: technique, I am a rank amateur but have learned the basics from instruction: Clean thoroughly until shiny, don't handle, flux x 2, heat fitting only, test for readiness with solder tip, clean up afterwards).

Profound thanks in advance. I feel I may have bit off a bit more than I can chew but I'm too close to quit.