Hello All!

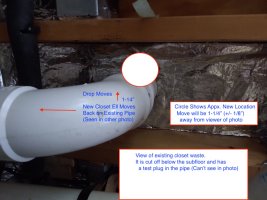

At home, we are re-working a bathroom. The toilet will be moved. The move is 3" toward the stack and over 1.25". My trouble is that the length of the pipe from stack to toilet and the height to the subfloor is too small for rolling offsets to move 1.25" Unfortunately, some years ago I replaced the bell-and-spigot with schedule 40 PVC, so i can't simply rotate the waste pipe fitting into the stack.

I studied rolling 45, 22-1/2, 60 etc. No luck, so I thought about an offset closet flange. The ones I looked at all have a shelf below the inlet. It looks like the material drops from the toilet onto the shelf, then I suppose water washes the shelf.

Somehow that does not seem like it would work well with a modern toilet, especially power flush. Do you guys know if there is an offset closet flange that is not troublesome?

Thanks For Helping!

Paul

At home, we are re-working a bathroom. The toilet will be moved. The move is 3" toward the stack and over 1.25". My trouble is that the length of the pipe from stack to toilet and the height to the subfloor is too small for rolling offsets to move 1.25" Unfortunately, some years ago I replaced the bell-and-spigot with schedule 40 PVC, so i can't simply rotate the waste pipe fitting into the stack.

I studied rolling 45, 22-1/2, 60 etc. No luck, so I thought about an offset closet flange. The ones I looked at all have a shelf below the inlet. It looks like the material drops from the toilet onto the shelf, then I suppose water washes the shelf.

Somehow that does not seem like it would work well with a modern toilet, especially power flush. Do you guys know if there is an offset closet flange that is not troublesome?

Thanks For Helping!

Paul