Tyann98

New Member

We're having a slight issue with our well pump we can't figure out.

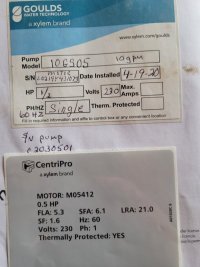

We had a Xylem Goulds 1/2 hp well pump (model 10GS05) installed new in 2020. Our well is 52 feet. Pressure switch is 30/50. I'm not sure exactly what the size of the pressure tank is - I think maybe about a 20 gal vertical due to the size of it.

Just recently, once or twice a week, the pump has been shutting off and so we lose water pressure, and it seems to be when only one particular shower in the house is being used.

At first, we assumed it was the pressure switch acting up. The contacts did look a bit crusty. We flipped that out with a new switch, but a week later, the same problem happened again. While the shower was being used, I watched the gauge, and it appears that the pump is shutting off before 50 psi can be reached, and remains off, and eventually the pressure tank empties from the shower. The pressure switch remains on - an voltage detector shows that power is still being provided from the switch, through the control box and out to the pump. If we wait a bit, flip the breaker a couple of times, it comes back on and we don't have a problem again for awhile. We have no issues with losing any pressure when there isn't any water being used.

It appears that the pump's thermal shutoff is being tripped? But I'm not sure why. This has happened about 5 times now, and only when this one particular shower in the house is being used for 5+ minutes. The shower must have high water draw and it seems to be overloading our pump, but I'm not sure why this hasn't been a problem until now. Is there something wrong with the pump or the control box? Or maybe an issue with the pressure tank that I don't understand? The pressure gauge seems to match the pressure when measured at the tank. Everything looks like its working as it should to me. The pump is under warranty for another 4 months, so I'm not sure if I sure pursue looking into replacement or not. I'll definitely look into installing a lower flow shower head, but if there's a bigger problem, I wanted some advice where to start.

Thank you!

We had a Xylem Goulds 1/2 hp well pump (model 10GS05) installed new in 2020. Our well is 52 feet. Pressure switch is 30/50. I'm not sure exactly what the size of the pressure tank is - I think maybe about a 20 gal vertical due to the size of it.

Just recently, once or twice a week, the pump has been shutting off and so we lose water pressure, and it seems to be when only one particular shower in the house is being used.

At first, we assumed it was the pressure switch acting up. The contacts did look a bit crusty. We flipped that out with a new switch, but a week later, the same problem happened again. While the shower was being used, I watched the gauge, and it appears that the pump is shutting off before 50 psi can be reached, and remains off, and eventually the pressure tank empties from the shower. The pressure switch remains on - an voltage detector shows that power is still being provided from the switch, through the control box and out to the pump. If we wait a bit, flip the breaker a couple of times, it comes back on and we don't have a problem again for awhile. We have no issues with losing any pressure when there isn't any water being used.

It appears that the pump's thermal shutoff is being tripped? But I'm not sure why. This has happened about 5 times now, and only when this one particular shower in the house is being used for 5+ minutes. The shower must have high water draw and it seems to be overloading our pump, but I'm not sure why this hasn't been a problem until now. Is there something wrong with the pump or the control box? Or maybe an issue with the pressure tank that I don't understand? The pressure gauge seems to match the pressure when measured at the tank. Everything looks like its working as it should to me. The pump is under warranty for another 4 months, so I'm not sure if I sure pursue looking into replacement or not. I'll definitely look into installing a lower flow shower head, but if there's a bigger problem, I wanted some advice where to start.

Thank you!