thelinuxfan

New Member

Hello! I have a Grundfos booster pump that connects to two storage tanks. Every once in awhile, someone leaves water running and the storage tank runs out of water. When this happens, the system will not pressurize until the water level in the storage tank reaches the pressure gauge. If I power cycle the pump, it will work but cannot maintain the pressure. The system works until the water is below the outlet of the tank, but we have to wait until it reaches the gauge.

Why does the system need to be at such a high level to work? We have to wait until there are nearly 300 gallons in the tank to work when it works with only < 50 gallons before it runs out. I am sure gravity has a role somewhere in this issue.

Even if I can't resolve it, I'd like to understand why the problem exists.

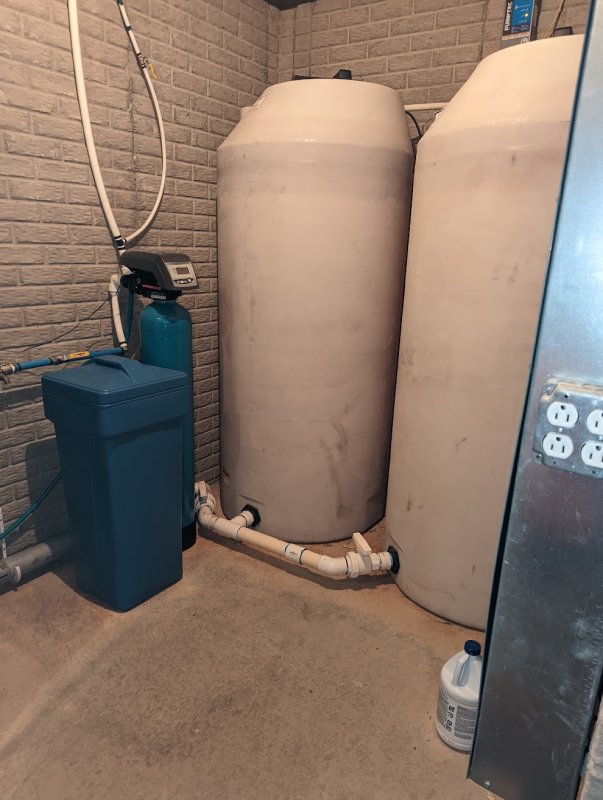

I am not home right now. My wife let me know it occurred, but I have some pictures saved. The first picture is where the gauge is located. That line goes into the pex you can see in the next picture near the water softener.

Thanks!

Why does the system need to be at such a high level to work? We have to wait until there are nearly 300 gallons in the tank to work when it works with only < 50 gallons before it runs out. I am sure gravity has a role somewhere in this issue.

Even if I can't resolve it, I'd like to understand why the problem exists.

I am not home right now. My wife let me know it occurred, but I have some pictures saved. The first picture is where the gauge is located. That line goes into the pex you can see in the next picture near the water softener.

Thanks!