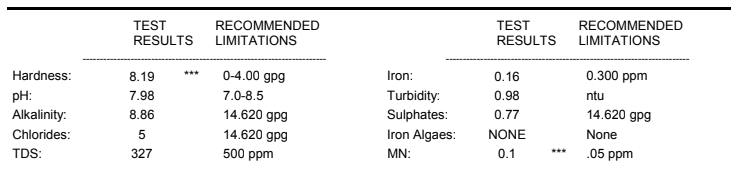

1. I now understand why I originally thought you had 1 cuft. "Capacity = 32k" would be marketing-speak for 1 cuft. But your first sentence was explicit with 1.5.

2. I also am suggesting C=30 and not 32. You might check other numbers to see if there are differences to think about.

3. Water tastes funny is ambiguous. "It's happening now and I Just verified that when I bypass the softener it goes away. " is not ambiguous. Did you sanitize your resin with bleach during installation? Some Fleck service manuals address that, but 5600SXT manual does not. See item 6 below. I am not saying that is causing your unwanted taste. The extra regen makes sense.

4. In retrospect, a 1 cuft softener might have been a better choice in your case, but I am not suggesting that you change it out.

5. Iron Out can be used as a batch treatment for a build-up of iron in the resin, and it can also serve as an additive to the salt.

6.The following is from the 5800SXT service manual

SYSTEM DISINFECTION

Disinfection Of Water Softeners

The materials of construction of the modern water softener

will not support bacterial growth, nor will these materials

contaminate a water supply. During normal use, a softener

may become fouled with organic matter, or in some cases with

bacteria from the water supply. This may result in an off-taste

or odor in the water.

Some softeners may need to be disinfected after installation

and some softeners will require periodic disinfection during

their normal life.

Depending upon the conditions of use, the style of softener, the

type of ion exchanger, and the disinfectant available, a choice

can be made among the following methods.

Sodium or Calcium Hypochlorite

Application

These materials are satisfactory for use with polystyrene

resins, synthetic gel zeolite, greensand and bentonites.

5.25% Sodium Hypochlorite

These solutions are available by various sellers of household

bleach. If stronger solutions are used, such as those sold for

commercial laundries, adjust the dosage accordingly.

1. Dosage

A. Polystyrene resin; 1.2 fluid ounce (35.5 ml) per cubic

foot.

B. Non-resinous exchangers; 0.8 fluid ounce (23.7 ml) per

cubic foot.

2. Salt tank softeners

A. Backwash the softener and add the required amount

of hypochlorite solution to the well of the salt tank. The

salt tank should have water in it to permit the solution

to be carried into the softener.

B. Proceed with the normal recharge.

Calcium Hypochlorite

Calcium hypochlorite, 70% available chlorine, is available in

several forms including tablets and granules. These solid

materials may be used directly without dissolving before use.

1. Dosage

A. Two grains (approximately 0.1 ounce [3 ml]) per cubic

foot.

2. Salt tank softeners

A. Backwash the softener and add the required amount of

hypochlorite to the well of the salt tank. The salt tank

should have water in it to permit the chlorine solution to

be carried into the softener.

B. Proceed with the normal recharge.

7.

https://terrylove.com/forums/index....izing-extra-attention-to-4-inch-casing.65845/ is my well and plumbing sanitizing write-up.