Brad Wilkinson

New Member

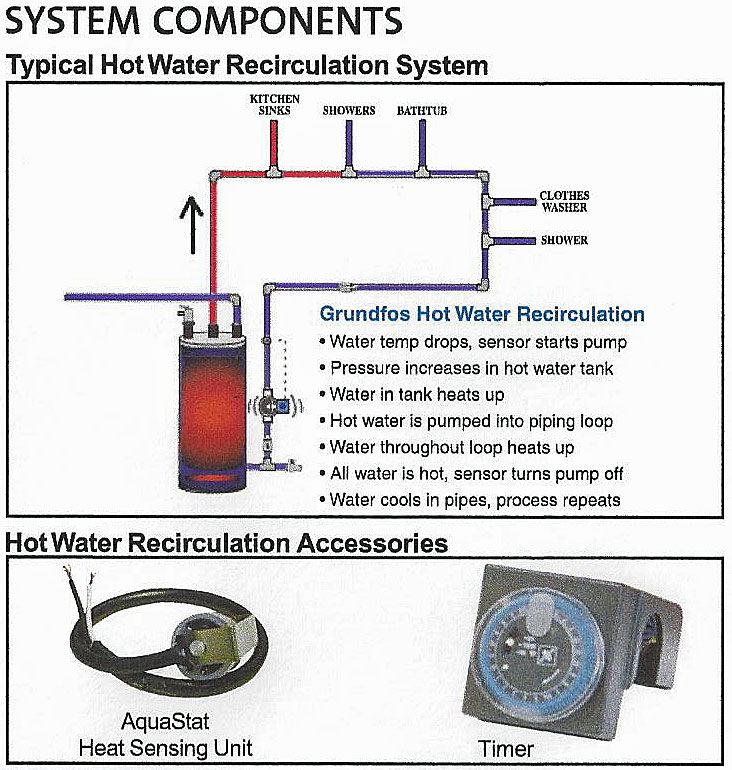

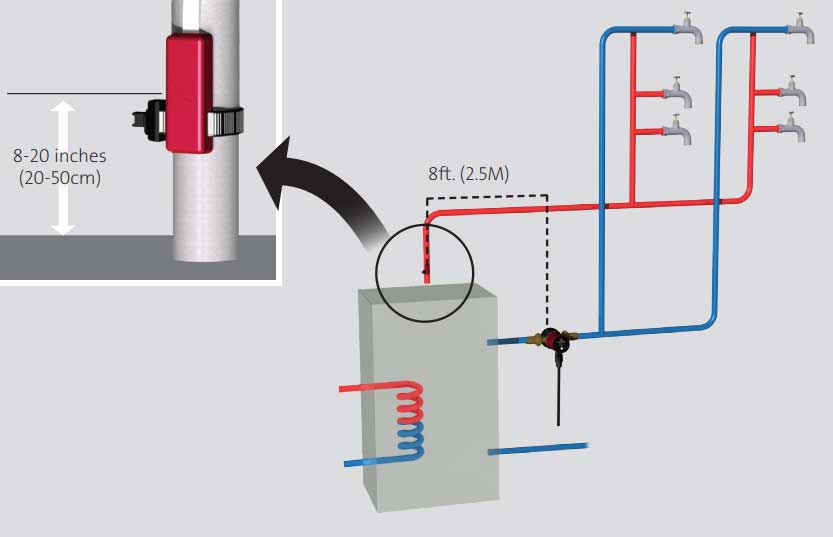

I just moved into my new house, where I got a looped hot water recirculation system installed. I had asked the plumber if he was installing a pump that would sense the water temperature and run as needed, and he said "Yes, it has a built-in temperature sensor, but they usually run all the time". So when I heard the pump stop and start regularly and constantly, I thought that was correct operation, it's about 150' round trip and I thought the water was cooling just enough in the return line to make the pump cycle some. Actually a lot, like every 5 seconds, on 2 seconds, off 3 seconds, over and over.

After spending the first night here, I noticed that all the hot water took a long time to heat up, exactly what I was trying to avoid. I thought maybe it was just that we hadn't been here and hadn't used any hot water and it was taking a while for the system to catch up. But that didn't make any sense - the recirculation loop should have hot water available at every fixture pretty quickly. Yes, some of the fixtures are several feet from the loop, and I expected a few seconds of cold water until the branch line was flushed, but it is taking minutes. The only time it is quicker is when we are using several things at once and the line is freshly hot. I have a 65 gallon heat pump water heater and it is doing fine, so it's not a supply problem at all. So this problem led me to check the recirculation pump a little closer - and it's cycling like I mentioned above - constantly.

Problem is, it's not cycling because of temperature drop, it's not a temperature-sensing pump like I asked for - it's a continuous one. The one they installed is the Grundfos UP 10-16 PM "Basic" model (98420210) that is supposed to be a 100% continuous operation pump. This is not the auto-adapt A model or even the temperature-sensing T model. So that's a disappointment right there, but if it was running continuously like it's supposed to, at least I would have quick hot water supply everywhere and that's not what I have.

Does anyone have any idea why it is cycling if it is supposed to run continuously? Is there something wrong with this pump?

Thanks,

Brad

After spending the first night here, I noticed that all the hot water took a long time to heat up, exactly what I was trying to avoid. I thought maybe it was just that we hadn't been here and hadn't used any hot water and it was taking a while for the system to catch up. But that didn't make any sense - the recirculation loop should have hot water available at every fixture pretty quickly. Yes, some of the fixtures are several feet from the loop, and I expected a few seconds of cold water until the branch line was flushed, but it is taking minutes. The only time it is quicker is when we are using several things at once and the line is freshly hot. I have a 65 gallon heat pump water heater and it is doing fine, so it's not a supply problem at all. So this problem led me to check the recirculation pump a little closer - and it's cycling like I mentioned above - constantly.

Problem is, it's not cycling because of temperature drop, it's not a temperature-sensing pump like I asked for - it's a continuous one. The one they installed is the Grundfos UP 10-16 PM "Basic" model (98420210) that is supposed to be a 100% continuous operation pump. This is not the auto-adapt A model or even the temperature-sensing T model. So that's a disappointment right there, but if it was running continuously like it's supposed to, at least I would have quick hot water supply everywhere and that's not what I have.

Does anyone have any idea why it is cycling if it is supposed to run continuously? Is there something wrong with this pump?

Thanks,

Brad