Chris in Redlands

Member

Hello! New member, though I spent a LOT of time researching here a few years ago when I remodeled our master bath from the studs out. I've started in on the main bath now, and thought the tub was going to be an "easy-button" job compared to building the shower from the ground up. Not so sure now.

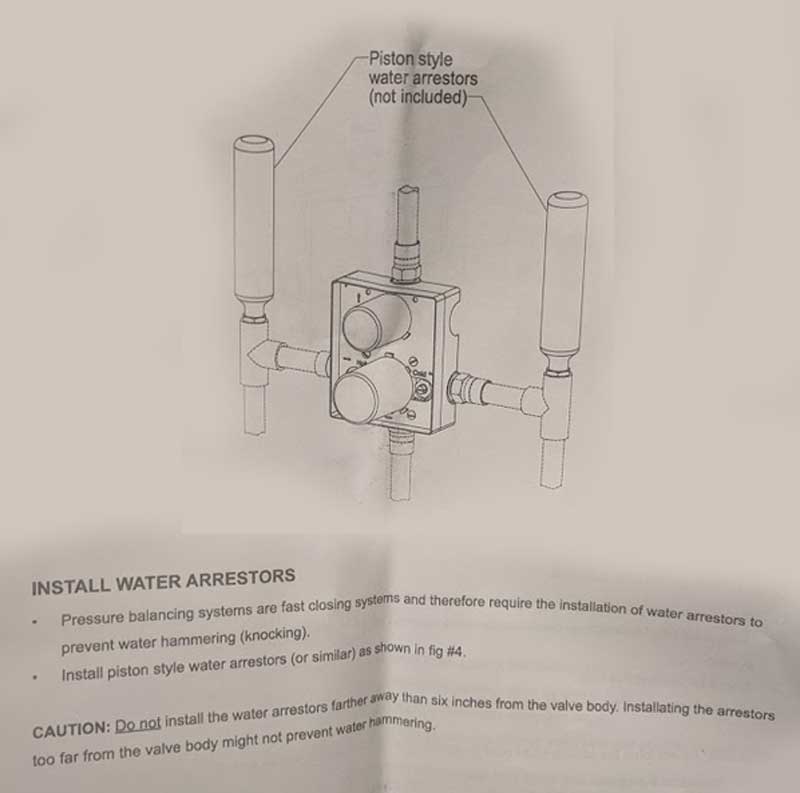

At the moment, I'm just finished with demolition, and am waiting for a custom window so i can re-frame all the termite-eaten exterior wall and get the new window in, plumb in new shower/bath valve and hardware, then install the tub.

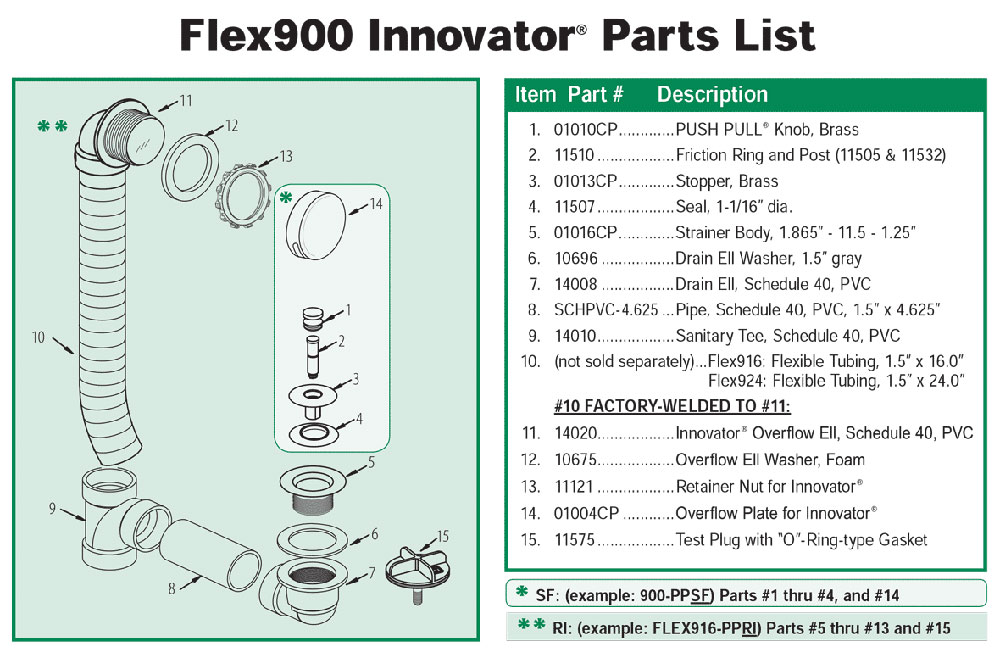

I picked up a Kohler Villager cast iron tub yesterday, which is currently in my garage. The tub I removed was a similar left-drain cast iron alcove tub. The drain/overflow was all brass, and I was thinking I'd use the Everbilt Twist and Close 1-1/2 in. 20-Gauge Brass Pipe Bath Waste and Overflow Drain available at the local big box. This guy:

The house is slab on grade with stucco exterior walls. the plumbing is within a wet wall that is shared with the master bath, and is a narrow "box" defined by two stud walls of "sideways" studs. There is tub drain access hole on the exterior wall. Here's a picture:

The drain is set in poured concrete and is a standard 1 1/2 inch ID iron pipe, I assume as old as the house (1956). It has about 3/8 inch of good thread.

I had to give the threaded ring that was attached to that a good few days' soaking of sneaky pete followed by a good heating with a torch to get it off in one piece, and it's pretty mangled, but still serviceable, minus the rubber ring that was inside it. I mention that because it doesn't appear that the everbilt drain comes with this part.

I have read all of the instructions for both the tub and the drain/overflow, and both assume I know a lot more about plumbing than I do. Most videos out there show installations where easy access is available to the drain from the wall behind it. In this case, the wall behind it is the master bath shower. The exterior access hatch is in a position where you have to be a contortionist to actually use it to access the drain. I'm assuming i'll access it from the side by reaching around and through the wet wall after getting the tub in position.

My question: How much of the drain hardware *must* be attached to the tub before putting the tub in position? Most things I see have it all attached, but this tub is such a pig, I'm worried i'll bang it up while wrestling it into the alcove. I feel like pre-assembling the drain/overflow parts to a good dry fit on the tub, then removing the assembled drain/overflow parts, and sliding that into the drain pipe in the floor, THEN positioning the tub, and attaching the overflow and drain inside the tub, then tightening the sleeve on the iron pipe over the slip-in would be the way to go.

Thoughts? I want to get this right, since everything will be good and built in and tiled over once this job is done.

Thanks!

At the moment, I'm just finished with demolition, and am waiting for a custom window so i can re-frame all the termite-eaten exterior wall and get the new window in, plumb in new shower/bath valve and hardware, then install the tub.

I picked up a Kohler Villager cast iron tub yesterday, which is currently in my garage. The tub I removed was a similar left-drain cast iron alcove tub. The drain/overflow was all brass, and I was thinking I'd use the Everbilt Twist and Close 1-1/2 in. 20-Gauge Brass Pipe Bath Waste and Overflow Drain available at the local big box. This guy:

The house is slab on grade with stucco exterior walls. the plumbing is within a wet wall that is shared with the master bath, and is a narrow "box" defined by two stud walls of "sideways" studs. There is tub drain access hole on the exterior wall. Here's a picture:

The drain is set in poured concrete and is a standard 1 1/2 inch ID iron pipe, I assume as old as the house (1956). It has about 3/8 inch of good thread.

I had to give the threaded ring that was attached to that a good few days' soaking of sneaky pete followed by a good heating with a torch to get it off in one piece, and it's pretty mangled, but still serviceable, minus the rubber ring that was inside it. I mention that because it doesn't appear that the everbilt drain comes with this part.

I have read all of the instructions for both the tub and the drain/overflow, and both assume I know a lot more about plumbing than I do. Most videos out there show installations where easy access is available to the drain from the wall behind it. In this case, the wall behind it is the master bath shower. The exterior access hatch is in a position where you have to be a contortionist to actually use it to access the drain. I'm assuming i'll access it from the side by reaching around and through the wet wall after getting the tub in position.

My question: How much of the drain hardware *must* be attached to the tub before putting the tub in position? Most things I see have it all attached, but this tub is such a pig, I'm worried i'll bang it up while wrestling it into the alcove. I feel like pre-assembling the drain/overflow parts to a good dry fit on the tub, then removing the assembled drain/overflow parts, and sliding that into the drain pipe in the floor, THEN positioning the tub, and attaching the overflow and drain inside the tub, then tightening the sleeve on the iron pipe over the slip-in would be the way to go.

Thoughts? I want to get this right, since everything will be good and built in and tiled over once this job is done.

Thanks!