Existing 1700sqft 3bd/2bath home has a 115' 6" well with a 1/2hp submersible pump. Town records show well yield at 10gpm. Plumbing from well (not sure of drop pipe yet) to pressure tank in home is 1-1/4". Piping is about 50' and level run. Pressure tank was just replaced due to age related failure and upgraded to 120g. 1" hot and cold mains run from the pressure tank through the rest of the house. Home currently occupied by a family of 3. Currently system works ok though pressure and volume were previously issues with the smaller pressure tank. Since adding the new pressure tank at 50/70 psi and increasing the size it has helped.

Due to some family matters an addition with an in-law apt will be added on. This will add another 3 people and 2 bedrooms and 2 baths bringing the home to a 6 people and 5 bedroom/4 bath home. The septic system will also need to be addressed though thats a separate topic. With that in mind I figure the water system design needs to allow for 12-18gpm. GPM is estimated ooff the total fixture count, simultaneous use, and desired PSI/flow to achieve as close to city water as possible.

With the the well yield being at 10gpm Im thinking an underground cistern will need to be added to the system so that proper volume is available. ?maybe 1200g tank (6 people x 100g/day x 2days)? Because of the increased volume pressure upgrades to the filtration (sediment, neutralizer, softener, UV) after the well pump are also planned off of a 1-1/4" manifold to accommodate 12-18gpm.

what I dont fully understand is around how to select and install the right submersible pump in/to the cistern. From what I read I think I want the pump in the cistern and for it to be installed in a vertical manner.

- are there any links where I can learn more about this type of setup?

- How does that work without a well casing?

- How do you keep it firmly in place and ensure that it has it being properly cooled when water in the tank runs low?

- What controls to I need to leverage my existing well pump and pressure switch while adding the cistern submersible?

- Float switches, I know I need them, type, how high/low?

- what type of connection is needed to the cistern? Read something about a flexible connector?

- is there some type of drain required by code for the underground cistern? how does that work?

- any other considerations for the cistern/well?

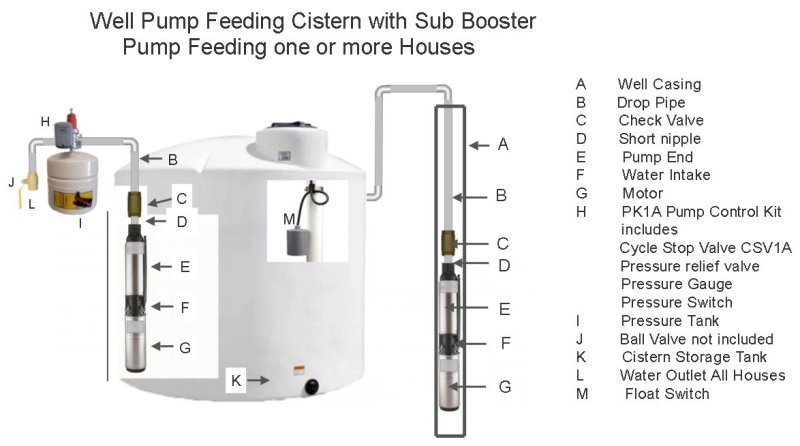

Something similar to this is what Im thinking.

Due to some family matters an addition with an in-law apt will be added on. This will add another 3 people and 2 bedrooms and 2 baths bringing the home to a 6 people and 5 bedroom/4 bath home. The septic system will also need to be addressed though thats a separate topic. With that in mind I figure the water system design needs to allow for 12-18gpm. GPM is estimated ooff the total fixture count, simultaneous use, and desired PSI/flow to achieve as close to city water as possible.

With the the well yield being at 10gpm Im thinking an underground cistern will need to be added to the system so that proper volume is available. ?maybe 1200g tank (6 people x 100g/day x 2days)? Because of the increased volume pressure upgrades to the filtration (sediment, neutralizer, softener, UV) after the well pump are also planned off of a 1-1/4" manifold to accommodate 12-18gpm.

what I dont fully understand is around how to select and install the right submersible pump in/to the cistern. From what I read I think I want the pump in the cistern and for it to be installed in a vertical manner.

- are there any links where I can learn more about this type of setup?

- How does that work without a well casing?

- How do you keep it firmly in place and ensure that it has it being properly cooled when water in the tank runs low?

- What controls to I need to leverage my existing well pump and pressure switch while adding the cistern submersible?

- Float switches, I know I need them, type, how high/low?

- what type of connection is needed to the cistern? Read something about a flexible connector?

- is there some type of drain required by code for the underground cistern? how does that work?

- any other considerations for the cistern/well?

Something similar to this is what Im thinking.