Platypus23

New Member

Hi everyone, first post here. I recognized at least one name here from the John Bridge Tile Forum, so if the forum quality carries over, I've come to the right place. That person will may recognize my long-winded, full-of-background-info question style  .

.

My situation is that I have to replace the sub-floor in a bathroom and laundry room, including a rotten joist from both an old bathtub leak and the fact that the house was built without house-wrap or flashing and the entire rim band and sub-floor at the edge of the house where the deck attached to the building (without flashing) has rotten out. Through careful application of emergency automotive jacks, ingenuity, sweat and occasional foul language, I've been able to lift the load-bearing exterior wall enough to tuck in new plywood sub-floor on top of the new rim joist and I've done three sections of plywood in the master bedroom already. So I have an approach. But I still need to do three more sections (12 feet along the edge of the house) that sit under the small master bath and laundry room on the other side of the wall. These are trickier than empty bedroom space and will require demo of the MBR. Not thrilled about the work here, but thankful that the 9-foot-high deck that was attached to that rotten rim joist stayed in the air long enough for me to still be alive to ask this question.

Bottom line is that I will need to cut the drains and water supplies in the master bathroom, as they penetrate the sub-floor that is being replaced. I also see it as an opportunity to right some past wrongs, like installing water hammer arrestors when I re-plumb the MBR bathroom, so it's worthwhile work aside from the fact that we all just wanted the stupid deck replaced, and cared nothing for doing a ridiculous, involved, time-consuming, "unnecessary", and expensive house repair first.

After surveying the existing plumbing, I note that the original water supply routes appear odd to me, but my plumbing experience is limited.

This is a good time to share my plumbing experience level. I've built three showers in other houses (thanks once again John Bridge and company!). I've installed a few new drain lines in this house, about 50' or so, extended the building drain for one of them to add a laundry sink to my garage. I know my around PEX and have the basic tools for it, and I know how not to bungle the installation of it. I understand drain venting. But, if there is some voodoo to the way that supply lines are run I know not of it, so I came here.

The way the current water supplies run, cold water comes in from the well system, forks off and runs toward the water heater, and the other fork goes out to a tee and branches off to the rest of the house from there. Pressure matters for cold too, but I don't ever have to wait for cold water, so meh.

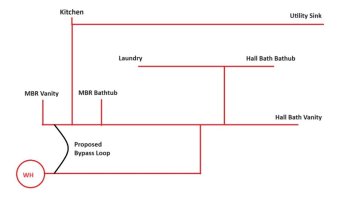

The hot water path is what seems odd to this novice. From the water heater, it runs about ten feet and then turns at an elbow for a foot or two, then hits a tee. One branch goes off to a different bath and the laundry, and a second branch then runs back toward the WH and has three tees directly off of it -- one to the kitchen, one to the master bath tub (being replaced), and the final one to the master bath vanity. So it ends up running all the way back to literally three feet from that final termination at the master bath vanity. It takes longer to get hot water in the bathroom right above the WH than it does to get it in a room 16 feet away.

Lots of words, I know... I attached a drawing.

My guess is that running out 10' to the first tee makes it so that the distances to the terminations is all equalized (as well as it can be) to mitigate pressure drops. Not sure how the single branch with three outlets (now four after adding the laundry tub beyond the kitchen) keeps up the equalization of distance/pressure.

But another guess is "they was drunk". Or they didn't like soldering (or liked it too much).

I have the opportunity to change the layout here. I was thinking that if you created a loop (the bent black line in the drawing) just after the WH and every tee off of that loop essentially has two feeds from each side, you could potentially alleviate some pressure drop issues. Essentially, what Iwill might be doing is keeping the existing path, but also adding a short circuit right from the WH to the last fixture on that second tortuous (near the MBR vanity).

On paper, this seems like it would balance the load, and the kitchen and utility sink would benefit immensely from losing about 15 feet of extra path. It's already about 30 miles just to the kitchen.

On the back of the paper, however, it might create one problem and not really fix the first one. The back of the paper might say that since the water has two paths to anywhere, it will take both paths, thereby wasting heat by filling up twice as much pipe.

Also, after reviewing the drawing, wouldn't it make sense to make another bypass from the laundry supply straight over to the left to tie in with the kitchen? I probably won't do it, but I could also bypass from the hall bathtub directly up to the utility sink

If this were electrical, I would already know that loops/bypasses in the hot are NOT cool (I have one of those cross-branch situations in this albatross house, still need to find it and break the connection, I suspect a bad DIY ceiling fan install). But this is plumbing. WHich side of the paper is wrong? Loops bad or loops good? Or is it bad in Hot but always good in cold supply lines for pressure balancing? Does water take the shortest path like electricity? Does it "mostly" take the shortest path when under pressure?

Finally, if looping is a bad idea, would it still be a good idea to bypass where I am suggesting, then CUT the part that runs off for ten feet. So, no loop, but a shorter path to most fixtures, and essentially the same length to the Hall bath and laundry supply? It comes down to "should the feed into a manifold be in the middle of the manifold, or is it OK to have it feed in from one end? Feeding in the middle seems more balanced, but only if it is very short. It's OK to tell me I am over-thinking it. I just want to know.

My situation is that I have to replace the sub-floor in a bathroom and laundry room, including a rotten joist from both an old bathtub leak and the fact that the house was built without house-wrap or flashing and the entire rim band and sub-floor at the edge of the house where the deck attached to the building (without flashing) has rotten out. Through careful application of emergency automotive jacks, ingenuity, sweat and occasional foul language, I've been able to lift the load-bearing exterior wall enough to tuck in new plywood sub-floor on top of the new rim joist and I've done three sections of plywood in the master bedroom already. So I have an approach. But I still need to do three more sections (12 feet along the edge of the house) that sit under the small master bath and laundry room on the other side of the wall. These are trickier than empty bedroom space and will require demo of the MBR. Not thrilled about the work here, but thankful that the 9-foot-high deck that was attached to that rotten rim joist stayed in the air long enough for me to still be alive to ask this question.

Bottom line is that I will need to cut the drains and water supplies in the master bathroom, as they penetrate the sub-floor that is being replaced. I also see it as an opportunity to right some past wrongs, like installing water hammer arrestors when I re-plumb the MBR bathroom, so it's worthwhile work aside from the fact that we all just wanted the stupid deck replaced, and cared nothing for doing a ridiculous, involved, time-consuming, "unnecessary", and expensive house repair first.

After surveying the existing plumbing, I note that the original water supply routes appear odd to me, but my plumbing experience is limited.

This is a good time to share my plumbing experience level. I've built three showers in other houses (thanks once again John Bridge and company!). I've installed a few new drain lines in this house, about 50' or so, extended the building drain for one of them to add a laundry sink to my garage. I know my around PEX and have the basic tools for it, and I know how not to bungle the installation of it. I understand drain venting. But, if there is some voodoo to the way that supply lines are run I know not of it, so I came here.

The way the current water supplies run, cold water comes in from the well system, forks off and runs toward the water heater, and the other fork goes out to a tee and branches off to the rest of the house from there. Pressure matters for cold too, but I don't ever have to wait for cold water, so meh.

The hot water path is what seems odd to this novice. From the water heater, it runs about ten feet and then turns at an elbow for a foot or two, then hits a tee. One branch goes off to a different bath and the laundry, and a second branch then runs back toward the WH and has three tees directly off of it -- one to the kitchen, one to the master bath tub (being replaced), and the final one to the master bath vanity. So it ends up running all the way back to literally three feet from that final termination at the master bath vanity. It takes longer to get hot water in the bathroom right above the WH than it does to get it in a room 16 feet away.

Lots of words, I know... I attached a drawing.

My guess is that running out 10' to the first tee makes it so that the distances to the terminations is all equalized (as well as it can be) to mitigate pressure drops. Not sure how the single branch with three outlets (now four after adding the laundry tub beyond the kitchen) keeps up the equalization of distance/pressure.

But another guess is "they was drunk". Or they didn't like soldering (or liked it too much).

I have the opportunity to change the layout here. I was thinking that if you created a loop (the bent black line in the drawing) just after the WH and every tee off of that loop essentially has two feeds from each side, you could potentially alleviate some pressure drop issues. Essentially, what I

On paper, this seems like it would balance the load, and the kitchen and utility sink would benefit immensely from losing about 15 feet of extra path. It's already about 30 miles just to the kitchen.

On the back of the paper, however, it might create one problem and not really fix the first one. The back of the paper might say that since the water has two paths to anywhere, it will take both paths, thereby wasting heat by filling up twice as much pipe.

Also, after reviewing the drawing, wouldn't it make sense to make another bypass from the laundry supply straight over to the left to tie in with the kitchen? I probably won't do it, but I could also bypass from the hall bathtub directly up to the utility sink

If this were electrical, I would already know that loops/bypasses in the hot are NOT cool (I have one of those cross-branch situations in this albatross house, still need to find it and break the connection, I suspect a bad DIY ceiling fan install). But this is plumbing. WHich side of the paper is wrong? Loops bad or loops good? Or is it bad in Hot but always good in cold supply lines for pressure balancing? Does water take the shortest path like electricity? Does it "mostly" take the shortest path when under pressure?

Finally, if looping is a bad idea, would it still be a good idea to bypass where I am suggesting, then CUT the part that runs off for ten feet. So, no loop, but a shorter path to most fixtures, and essentially the same length to the Hall bath and laundry supply? It comes down to "should the feed into a manifold be in the middle of the manifold, or is it OK to have it feed in from one end? Feeding in the middle seems more balanced, but only if it is very short. It's OK to tell me I am over-thinking it. I just want to know.

Attachments

Last edited: