Howard M Emerson

Member

- Messages

- 227

- Reaction score

- 18

- Points

- 18

- Location

- Huntington Station, NY

- Website

- www.howardemerson.com

Hello all,

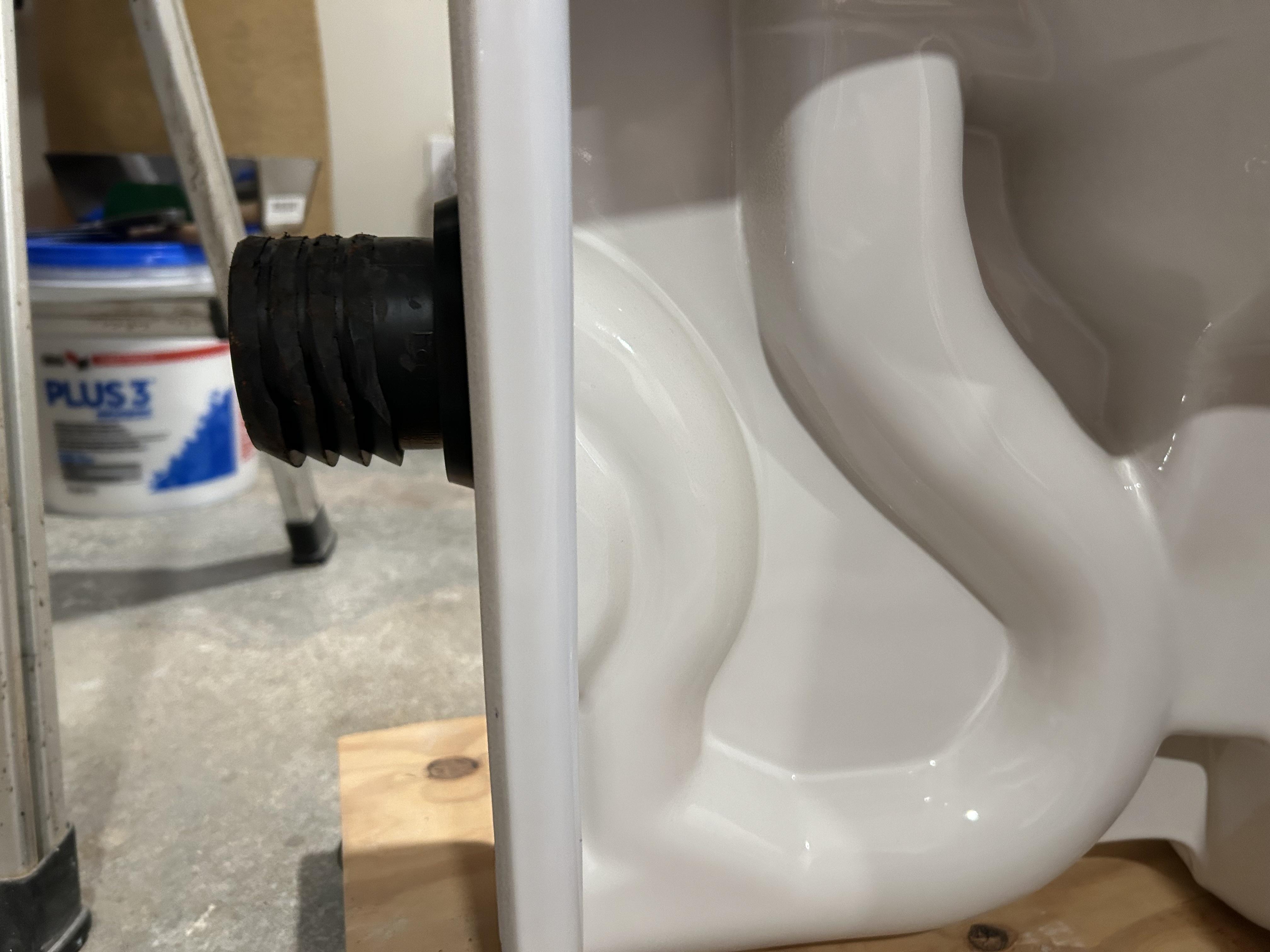

Long story short: Almost 30 years ago I had a plumber turn a toilet sideways to allow shower chair access for my paralyzed sister-in-law. Here's a picture of the cast iron flange/pipe that is 11 & 1/8" from the wall.

Here is the overall picture for context:

Another shot:

The toilet is a Toto Eco Ultramax. I also installed one in my master bathroom, and it's wonderful! It stops at nothing

The problem here, previously a concrete garage floor, is that I only have 11 & 1/8" to the flange bolt centers, so I need to install an offset flange. Upstairs I installed it with 11 & 1/2" from the wall, and it still has room behind the tank, but this ain't happening this time. By the way, I know exactly how and why this happened, and knew this might occur. I will not remove wall tile behind the toilet, so cutting cast iron is how I'm proceeding.

I'll be removing the stainless steel hex bolts later this morning, and I do not know what they're screwed into. The black arrow I drew shows what appears to be where a piece of cast iron pipe was inserted into the CI sweep elbow, but again it was almost 30 years ago, so I don't remember what that plumber did to facilitate the 90 degree turning of the toilet sideways. Anyway....

Given what you see in picture do any of you have a clue what is there? The collective knowledge on this forum always amazes me, so I am hopeful that what I'm showing will give some clues.

Best regards,

Howard Emerson

HUNTINGTON STATION, NY

Long story short: Almost 30 years ago I had a plumber turn a toilet sideways to allow shower chair access for my paralyzed sister-in-law. Here's a picture of the cast iron flange/pipe that is 11 & 1/8" from the wall.

Here is the overall picture for context:

Another shot:

The toilet is a Toto Eco Ultramax. I also installed one in my master bathroom, and it's wonderful! It stops at nothing

The problem here, previously a concrete garage floor, is that I only have 11 & 1/8" to the flange bolt centers, so I need to install an offset flange. Upstairs I installed it with 11 & 1/2" from the wall, and it still has room behind the tank, but this ain't happening this time. By the way, I know exactly how and why this happened, and knew this might occur. I will not remove wall tile behind the toilet, so cutting cast iron is how I'm proceeding.

I'll be removing the stainless steel hex bolts later this morning, and I do not know what they're screwed into. The black arrow I drew shows what appears to be where a piece of cast iron pipe was inserted into the CI sweep elbow, but again it was almost 30 years ago, so I don't remember what that plumber did to facilitate the 90 degree turning of the toilet sideways. Anyway....

Given what you see in picture do any of you have a clue what is there? The collective knowledge on this forum always amazes me, so I am hopeful that what I'm showing will give some clues.

Best regards,

Howard Emerson

HUNTINGTON STATION, NY