Thank you guys for all the hints and opinions. Honestly, when I first wrote to this forum I didn't know what to do. Local professionals were giving so much different solutions to the same problem. The system I've bought had 6gpm on 12 inch tank, which clogged within a month.

Yesterday I made another iron test and got 0.13 ppm right out of the new filter (incoming is about 4.5 ppm). I think, this is a great progress!

Should the iron filter remove all the iron or some traces below 0.3 ppm is acceptable?

I'll try to address all your concerns here:

I would like more... maybe dancing around the bottom of your top basket, if you could.

I'm sorry, but I think I don't understand what is top basket... Is this the top of the tank? or bottom of the head?

Forum member Ditttohead is a water treatment equipment distributor. He has tested KL media and has recommended the BW rate to be 10 - 15 GPM/ft2. In consideration of the 0.54 ft2 cross section for a 10" tank, the recommended DLFC will then be 5.4 - 8.1 GPM.

As there are further compensation factors for water temperature, the DLFC rate will need to be reduced if the backwash water is cooler than 60℉.

https://view.publitas.com/impact-water-products/2018-catalog-final/page/155

My water temperature is about 13C, which is 55.4F, so from this perspective myy 7.6gpm could be at the very top of the suggested flow by Ditttohead. Please correct me if I'm wrong.

A 10 inch tank is 5.55 sqft.

12 gpm/ft2 is less than optimum IMO. Have you seen the graph, and my table which is derived from the graph? I suspect that number you are looking at is largely influenced by the marketing people. Backwash water temperature is significant.

Yes, I've seen it, thank you. I feel the same about sales people

Unfortunately, too much of my background information is from some commercials ...

How does that 16% expansion compare to the height of the bottom of your top basket?

I'm not very sure about the terminology, but I have another 6 inches to the end of the tank(another 16%) and about 2.5 inches till the point where the tank starts curving.

Suggest installing an 8 GPM DLFC and then perform an extended manual BW. Upon advancing the controller to BW, remove the controller's electrical plug to prevent the controller from advancing to the following cycle. This will then allow the BW cycle to continue until the drain water is fully clear.

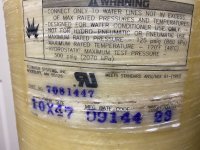

I installed the hose connector(no restriction) and was able to see 8.2gpm. This gave me another 1.5 inch of media expansion. In general, the drain water is quite clean (even from iron) in about 3 minutes after the start. I'm doing backwash cycles once per day right now.

Looks like I need to reduce my bead depth from 39 till 30 inches as suggested...