The switch is plenty close to the tank. That makes me think the tank is waterlogged or has too much air charge.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Deepening well to install geothermal system

- Thread starter Twotone

- Start date

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)

I think the pressure switch on the tank tee is not wired up, and he is using the black pressure switch that is on the pump.The switch is plenty close to the tank. That makes me think the tank is waterlogged or has too much air charge.

Twotone:

- Could you re-wire to use the pressure switch that is up by the pressure gauge? That would be best.

That "sampling port" is usually called a drain valve. It is low, with respect to the tank, to let you drain the sediment periodically. Most people have a garden hose thread connection on that, which lets them route the sediment with a hose. Your health department may object to threads. So you will need to drain into buckets.Edit: I now see that you have two faucets, and one has threads.- You could check the pressure tank by shutting off the water to the house with the valve after the pressure tank. Pump to 50 psi. Turn off the power to the pump. Then drain the pressure tank into buckets. Expect around 25% of the pressure tank size to drain into the bucket(s). If you get a lot less, there is a pressure tank problem. I am not predicting a pressure tank problem.

Last edited:

Sponsor

Paid Advertisement

Twotone

New Member

Thanks, Reach is correct the switch on the tank manifold is not wired. I moved the switch on the tank manifold to the motor/jet location. No change to the chattering. I read valveman's post on the check valve between the pump and tank. I attempted to remove it. It is frozen on the manifold. I cleaned the exposed threads, sprayed it with penetrating oil, heated check valve with propane torch, sprayed manifold with freeze spray. I cannot break it loose. Manifold feels like its about to give. I've beat on it with a dead blow plastic covered hammer. I've tried tightening it but cannot budge it. Any suggestion on freeing it up? Brass tank tee manifold and brass or bronze check valve.

Long story short I back flushed the check valve with the gravity flow from the tank when the hose and connection had been removed. I also had removed the mini sample tap on the check valve. I had pushed on the check valve with my finger. Travel seemed ok. During the back flushing after all the above activity dirty water flushed out. It was late last night and I needed to get the water back on for us to get ready for work this morning.

I put everything back together and pump switch worked as it should. After a shower this morning the pump switch was not chattering.

Could it have been trash/new well sand in the check valve? Has worked since 2007 in the current configuration.

Reach thanks for the tip on using the tee manifold location on the pressure switch, I'll do that. I have drained the tank several time investigating. Drained pressure is 28 psi. Switch 30/50. The very first time I drained it air pressure blew out after as the water finished draining. There is a threaded garden hose connection in the second photo beside the new one. It has a spring loaded vent on it and leaks as the pressure gets low. Anti back siphon? The health department requested the non-threaded valve that the driller just put in. The health department hasn't came out yet. The pressure tank maintains the 28 psi when empty on the bladder charge valve stem. No water spews out the valve core when depressed at 50 psi. I'll do the 50 psi volume test as well.

I plan over the next week to relocate the storage tank and jet pump to the other end of the basement. I plan to install the CSV as well.

Valveman, when the sub pump is routed through the geo unit and discharging into the atmospheric storage tank is there any value in putting a CSV on it?

Any other reconfiguration improvement tips you can see?

Thanks for the help.

Long story short I back flushed the check valve with the gravity flow from the tank when the hose and connection had been removed. I also had removed the mini sample tap on the check valve. I had pushed on the check valve with my finger. Travel seemed ok. During the back flushing after all the above activity dirty water flushed out. It was late last night and I needed to get the water back on for us to get ready for work this morning.

I put everything back together and pump switch worked as it should. After a shower this morning the pump switch was not chattering.

Could it have been trash/new well sand in the check valve? Has worked since 2007 in the current configuration.

Reach thanks for the tip on using the tee manifold location on the pressure switch, I'll do that. I have drained the tank several time investigating. Drained pressure is 28 psi. Switch 30/50. The very first time I drained it air pressure blew out after as the water finished draining. There is a threaded garden hose connection in the second photo beside the new one. It has a spring loaded vent on it and leaks as the pressure gets low. Anti back siphon? The health department requested the non-threaded valve that the driller just put in. The health department hasn't came out yet. The pressure tank maintains the 28 psi when empty on the bladder charge valve stem. No water spews out the valve core when depressed at 50 psi. I'll do the 50 psi volume test as well.

I plan over the next week to relocate the storage tank and jet pump to the other end of the basement. I plan to install the CSV as well.

Valveman, when the sub pump is routed through the geo unit and discharging into the atmospheric storage tank is there any value in putting a CSV on it?

Any other reconfiguration improvement tips you can see?

Thanks for the help.

That looks very inaccessible. Does that tank tee have a union on it on its way into the tank? If so, I am thinking you might put a union on the output copper pipe, and pull the tank tee away. Then you can get wrenches in place or big locking pliers. Maybe use a bench vise. I like the Milwaukee 10-inch curved jaw locking pliers.

I am looking at your steel shelf. If the tank were to the edge, you could get better access. If you move a pipe clamp or two, could you jack the tank base closer to the edge-- enough to allow access from below?

Perhaps pull the nipple and the gray pressure switch for better access.

I am looking at your steel shelf. If the tank were to the edge, you could get better access. If you move a pipe clamp or two, could you jack the tank base closer to the edge-- enough to allow access from below?

Perhaps pull the nipple and the gray pressure switch for better access.

Last edited by a moderator:

Valveman, when the sub pump is routed through the geo unit and discharging into the atmospheric storage tank is there any value in putting a CSV on it?

When controlling the pump to come on and off the same time as the heat pump, a ball valve to vary the flow is the only thing I can think of that you might want to add.

Twotone

New Member

That looks very inaccessible. Does that tank tee have a union on it on its way into the tank? If so, I am thinking you might put a union on the output copper pipe, and pull the tank tee away. Then you can get wrenches in place or big locking pliers. Maybe use a bench vise. I like the Milwaukee 10-inch curved jaw locking pliers.

I am looking at your steel shelf. If the tank were to the edge, you could get better access. If you move a pipe clamp or two, could you jack the tank base closer to the edge-- enough to allow access from below?

Perhaps pull the nipple and the gray pressure switch for better access.

Thanks, There is a union going into the tank, however there is a ball valve screwed onto the other side of the tee and a screwed fitting that is soldiered to the copper pipe going to the house. I did slide the tank closer to the edge of the shelf and unscrew the elbow going to the black hose from the check valve. I am able to put a 24" pipe wrench on the check valve. The tee feels like it will collapse if I put enough force on the pipe wrench.

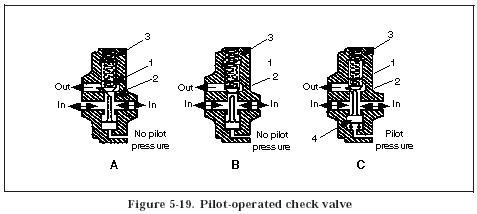

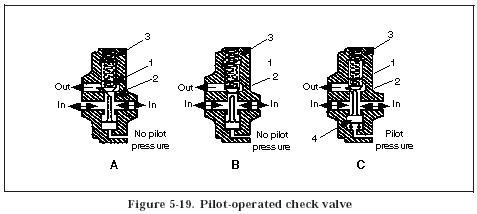

With some check valves, you can remove the poppet and spring. The check valve just becomes a connector. I have never done that. Here is a view of a check valve:I am able to put a 24" pipe wrench on the check valve. The tee feels like it will collapse if I put enough force on the pipe wrench.

Maybe see if yours might come apart.

I don't know if that would apply to your check valve. I am curious what the protrusions on your check valve are.

Last edited:

Twotone

New Member

I was curious too. It has (2) taps on the left discharge side. The one on the top is plugged. The one on the front side has a 1/4" sample/drain valve.

There are two protrusions on the inlet side that have not been drilled and tapped. There is one protrusion on the discharge that has not been tapped.

Found this image. Click on image for link.

Its working for now. When relocating the storage tank and adding an overflow outlet, the pressure tee will be out where I can attempt to remove its internals. The check valve body appears to be one piece. The nut on the guide stem can be taken out or twisted off maybe when removing the elbow on the inlet side, but removing the disc will be the problem. I could run two 1/4 inch bypass tubes from the inlet to the outlet side. I need to look at re-configuration to add the CSV that I purchased also. I need to get past the health inspection first.

On the geothermal startup.... The unit is running off the jet pump until overflow relocation. Working good. Thanks to all for the input.

There are two protrusions on the inlet side that have not been drilled and tapped. There is one protrusion on the discharge that has not been tapped.

Found this image. Click on image for link.

Its working for now. When relocating the storage tank and adding an overflow outlet, the pressure tee will be out where I can attempt to remove its internals. The check valve body appears to be one piece. The nut on the guide stem can be taken out or twisted off maybe when removing the elbow on the inlet side, but removing the disc will be the problem. I could run two 1/4 inch bypass tubes from the inlet to the outlet side. I need to look at re-configuration to add the CSV that I purchased also. I need to get past the health inspection first.

On the geothermal startup.... The unit is running off the jet pump until overflow relocation. Working good. Thanks to all for the input.

Twotone

New Member

Twotone

New Member

I looks like the CSV would replace the pressure tank tee.

The new picture clarifies. That is a tapped check valve. Those ports could have been used for a pressure switch or pressure gauge. The untapped boss would probably be before the disk or poppet, and would be used for a snifter valve for non-diaphragm air-on-water tank.

So you have 3 faucets there!

I suspect the tank tee would not collapse, but I could not know that for sure. Maybe unscrew the leaky hose valve, and stick a steel pipe into the hole as a handle. Then get some extra hands, and use the left faucet as a handle, the temporary steel pipe, and the tank outpipe trying to resist turning also. So three counter-torque sources to counter the loosening torque on the check valve.

So you have 3 faucets there!

I suspect the tank tee would not collapse, but I could not know that for sure. Maybe unscrew the leaky hose valve, and stick a steel pipe into the hole as a handle. Then get some extra hands, and use the left faucet as a handle, the temporary steel pipe, and the tank outpipe trying to resist turning also. So three counter-torque sources to counter the loosening torque on the check valve.

I looks like the CSV would replace the pressure tank tee.

Yes, the CSV1A has three extra ports that function as a tank tee.

Fitter30

Well-Known Member

Hard water and and geo system will run up maintenance cost and shorten its life with the water cooled condenser it will get limed up and have to be cleaned every year or two. Check with your supplier with the performance of a open system verses ground and differance in pump hp in ground to open system.

Hard water can cause an open loop heat pump to scale over. Not that hard to clean when needed. Pumping cost for an open loop system depends if water in your well is 20' deep or 400' deep. Shallow water needs less horsepower for the pump. Open loop systems can be very efficient. Closed loop systems can bank up heat in the ground and loose efficiency before the season changes.

I have an open loop system with a 1/3HP pump in hard water. In over 14 years I have never had a scaling problem. My system runs water through the heat pump 24/7, even when the heat pump is not on. When the heat pump is not on, the water flowing through erodes the scale off the coils and it has never needed cleaning.

I have an open loop system with a 1/3HP pump in hard water. In over 14 years I have never had a scaling problem. My system runs water through the heat pump 24/7, even when the heat pump is not on. When the heat pump is not on, the water flowing through erodes the scale off the coils and it has never needed cleaning.

Fitter30

Well-Known Member

1.5-2 gpm per ton of cooling

1.5-2 gpm per ton of cooling

Yep. My heat pump uses 4 GPM. And since I am pumping the water to cattle anyway, I just bring it by the house and steal all the heat or cool out of it on the way by. Pumping for the heat pump doesn't cost me a thing.

Similar threads

- Replies

- 9

- Views

- 245

- Replies

- 11

- Views

- 1K