You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pressure gage for water system - that won't fill with water?

- Thread starter AcidWater

- Start date

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)

Sponsor

Paid Advertisement

So any brand, but type liquid filled?I would opt for a liquid filled water pressure gauge.

This gage is at the bottom of the tank but I want one also to measure when the tank is valved out.

Would putting a gage directly on the top hole of the pump ruin the gage because of the constant pressure swings?

Shallow well (60 some feet) with a jet pump.

A while back my neighbor's footer valve leaked - the pump ran every couple minutes - and it lost its suction when power went out. We hooked up my hose to his outside bib to put water in, took forever to prime the thing. How much water ought it take to prime the pump? Do you have to fill the standpipe, or just fill the pump casing?

Explain bottom of the tank? Pressure tank?So any brand, but type liquid filled?

This gage is at the bottom of the tank but I want one also to measure when the tank is valved out.

Pressure switch is usually at the pressure gauge for a home well system. Pressure switch ideally should see the same pressure as the input of the pressure tank, and the easy way to do that is connect near the input to the pressure tank.

So wait, what about the pressure switches on the shallow well pumps, like you probably have? Those are not ideal. And since you have been having a problem, maybe you want to relocate the pressure switch to the pressure tank. So how would a pressure gauge at the output of the pump be? Not bad but not ideal.

So what would I use as a gauge? Not sure. Maybe 4 inch. Maybe smaller. Winters is a good brand, but maybe I would go cheaper.

https://www.supplyhouse.com/Temperature-Pressure-Gauges-864000

There are gauges with the connection in the back, and at the bottom, and even some others.

So for a shallow pump, I might consider an additional seldom-used gauge. How about a combination vacuum and pressure gauge on a tee at the input of the pump. High vacuum means water is low or some path is clogged. Low vacuum means the pump doesn't suck as much as it used to or there is a vacuum leak. Downside is that more stuff means more opportunities for vacuum leaks.

Last edited:

LLigetfa

DIYer, not in the trades

Some folks will install a ball valve before the gauge so the only time the gauge sees the pressure is when the valve is opened.Would putting a gage directly on the top hole of the pump ruin the gage because of the constant pressure swings?

Ball valve over the pump is an idea...

My pressure switch is attached directly to the pump. Don't think relocating it to near the floor where it might get wet is such a good idea, and the 1/8" tube would be very very long, so more air bubbles.

Now I'm wondering if it is necessary that the 1/8" tube be attached at the impeller, instead of anywhere in the piping?

Some other location would not get clogged with mud.

But if I left the pressure switch attached to the motor casing, the tube would bet pretty long, maybe be in the way, and longer means more filling with air...

The pump has outputs on top & to the side, but why else would they provide a small hole on the back of the impeller?

My pressure switch is attached directly to the pump. Don't think relocating it to near the floor where it might get wet is such a good idea, and the 1/8" tube would be very very long, so more air bubbles.

Now I'm wondering if it is necessary that the 1/8" tube be attached at the impeller, instead of anywhere in the piping?

Some other location would not get clogged with mud.

But if I left the pressure switch attached to the motor casing, the tube would bet pretty long, maybe be in the way, and longer means more filling with air...

The pump has outputs on top & to the side, but why else would they provide a small hole on the back of the impeller?

Not necessary. Closer to the pressure tank would be better.Now I'm wondering if it is necessary that the 1/8" tube be attached at the impeller, instead of anywhere in the piping?

Longer should not fill with air. Longer will not introduce pressure drop, because the flow is minuscule.

LLigetfa

DIYer, not in the trades

Having connections on the pump is a matter of convenience, not of good design. It lets the pump manufacturer ship a complete DIY solution in one package. Best practice is to make the connections at the tank Tee.The pump has outputs on top & to the side, but why else would they provide a small hole on the back of the impeller?

Elevating the switch and gauge on tall 1/4 inch riser pipes gets them up to keep them dry.

Having connections on the pump is a matter of convenience, not of good design. It lets the pump manufacturer ship a complete DIY solution in one package. Best practice is to make the connections at the tank Tee.

Elevating the switch and gauge on tall 1/4 inch riser pipes gets them up to keep them dry.

What LL says!

Your problem with sediment and failing foot valves could be greatly improved if not solved by eliminating the pump cycling on and off all the time, Not to mention how much better constant pressure is in the house and how much longer it will make your pump and tank last.

Also, why would you want an expensive oil filled pressure gauge when your cheap gauge lasted so many years?

Ballvalve

General Engineering Contractor

Some folks will install a ball valve before the gauge so the only time the gauge sees the pressure is when the valve is opened.

That works, but we all forget about snubbers and GOOD pressure gauges. WIKA is my gold standard and US made - High priced but many NOS items on Ebay not much more than junk imports. My China gauges were lasting a year and the WIKA's still going after 5+. https://www.google.com/search?q=pre...3j0i22i30l6.4844j0j7&sourceid=chrome&ie=UTF-8

LLigetfa

DIYer, not in the trades

Yesterday I was using my Victor tire pressure gauge and wondered why the needle would jump up after I took a reading. Turned out the needle was touching one of the two screw heads that holds the dial face on. I had to take it apart and bend the needle so it clears the screw head.

Bourdon tube pressure gauges are very susceptible to freezing damage and many places have them in outdoors or in unheated sheds rendering them questionable. It may be prudent to have on hand a gauge with garden hose thread that one can screw onto the draincock when needed. Store it in a warm place when not in use.

Bourdon tube pressure gauges are very susceptible to freezing damage and many places have them in outdoors or in unheated sheds rendering them questionable. It may be prudent to have on hand a gauge with garden hose thread that one can screw onto the draincock when needed. Store it in a warm place when not in use.

A pressure snubber is just a tiny hole in a washer before the gauge. These are notorious for clogging up. I prefer a gauge without a snubber as they don't stop up and show every vibration in the system where a "glycerin" filled or one with a snubber won't. Even gauges last longer with a constant pressure system as cycling and water hammer is hard on them as well.

LLigetfa

DIYer, not in the trades

Showing vibrations is a good thing when analyzing a system. Same sort of thing with an analog volt meter where a quivering needle gives clues....and show every vibration in the system

Cannot find the proper tubing. Searching for water pump pressure switch tubing gets all types of tubing, and no info on if it the correct type that will expand a bit when heated & then shrink on the barb.

The tubing I have needs a razor knife to cut off the barb & I'm afraid of nicking the brass & causing a leak.

The tubing I have needs a razor knife to cut off the barb & I'm afraid of nicking the brass & causing a leak.

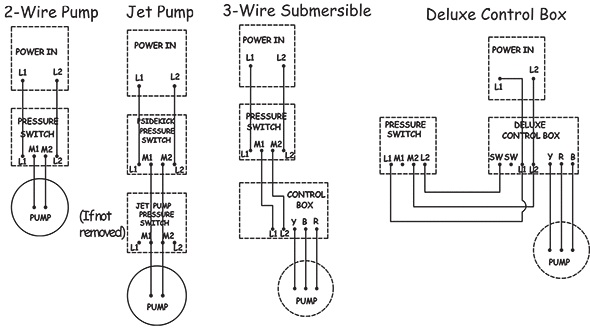

As was said, if the pressure switch line is getting clogged at the pump, move the pressure switch to the tank where it should be anyway. Just install a regular 1/4" lower pressure switch at the tank and wire around the existing switch on the tank as shown in the "jet pump" wiring here. Hard to find that tubing, just replace the switch.

To do what you are asking, you need 1/8 ID tube. You need a clamp that can clamp down on the ID. I don't have a product suggestion to do what you are asking for.Cannot find the proper tubing. Searching for water pump pressure switch tubing gets all types of tubing, and no info on if it the correct type that will expand a bit when heated & then shrink on the barb.

You already understand that we were thinking you should want something else.

To do what you are asking, you need 1/8 ID tube. You need a clamp that can clamp down on the ID. I don't have a product suggestion to do what you are asking for.

You already understand that we were thinking you should want something else.

It might not be exactly 1/8... maybe closer to 1/4" OD ? Maybe x/32" ? What is the standard ID for a barb on a 1/2" fitting?

Got a non-google URL? G is evil & I don't allow it on my computer.That works, but we all forget about snubbers and GOOD pressure gauges. WIKA is my gold standard and US made - High priced but many NOS items on Ebay not much more than junk imports. My China gauges were lasting a year and the WIKA's still going after 5+. https://www.google.com/search?q=pre...3j0i22i30l6.4844j0j7&sourceid=chrome&ie=UTF-8

Hard to find a Wika bottom mount.

And these two seem identical except for price (back mount) online:

WIKA 9318178

WIKA 9767215

Industrial Pressure Gauge, Liquid/Refillable, Copper Alloy Wetted Parts, 2-1/2" Dial, 0-100 psi Range, +/- 2/1/2% Accuracy, 1/4" Male NPT Connection, Center Back Mount

But it doesn't say if OK for potable water, a lot of gauges are not.

Last edited:

But it doesn't say if OK for potable water, a lot of gauges are not.

Lol! Even if it was made of solid lead it would be fine for potable water as long as the water is not hot or acidic. When you buy something that says rated NSF-61G for potable water, just know you are paying 4-5 times as much as you should for the government to say it is "safe" for potable water. I don't know how our ancestors survived to 90+ years drinking from leaded pipes and fittings, and using pumps made of leaded brass? Could it be that lead doesn't leach into the water unless the water is hot or acidic? Of course that is the case. But our government makes problems where there aren't any, so they can act like they are here to help us out. You could grind up and dissolve an entire leaded pressure gauge into the amount of water that would go past it in its life time and still not measure enough lead to hurt anyone. Flint is why there is such a push against lead in plumbing. But if you understand the problem, it was government officials who put acidic water through a lead service line that had been used without any problems for a hundred years. The problem was never lead in the pipes but stupid people in charge of the water system.

Get a digital caliper. You are next going to say it may not be a 1/2 inch NPT thread, but maybe 3/8 or 1/4 NPT.It might not be exactly 1/8... maybe closer to 1/4" OD ? Maybe x/32" ? What is the standard ID for a barb on a 1/2" fitting?

Last edited:

Similar threads

- Replies

- 1

- Views

- 239

- Replies

- 6

- Views

- 446

- Replies

- 6

- Views

- 422

- Replies

- 3

- Views

- 249