I've posted a couple threads about my 2" well. I decided to have a guy with a truck pull the drop pipe. The casing appears to be 96' and the static water is at 11' from the surface. There was only one stick of galvanized pipe with the jet at the bottom with a check valve. The well guy and I poured water down the casing and it didn't completely fill it up, but it did rise in the casing. The well guy said that is an indication that the well is bad. He said it might work to put a stick of schedule 80 on the bottom of the jet (He said the jet looked good so we just replaced the leathers and cleaned it) and put a new foot valve at the bottom of the tailpipe and sent it back down the casing. I should say this is just a one bedroom, one bathroom weekender in which I would use a very low volume of water. Unfortunately, like before, the pump will only pump a very small volume of water (like a crimped garden hose). He said it might be a screen well and it might work to pressurize the well casing with air using a high, high volume air compressor and if the screen is clogged, it could blow the screen out and cause the volume to increase. Is anyone familiar with this technique and is it worth even attempting? He said it would probably not work, but may be worth a try. If I have to drill a new well, I will trip a bunch of regulatory requirements that would be devastating and very, very expensive. Am I just out of luck or anyone have any ideas?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bad news concerning my well

- Thread starter catldavis

- Start date

Users who are viewing this thread

Total: 3 (members: 0, guests: 3)

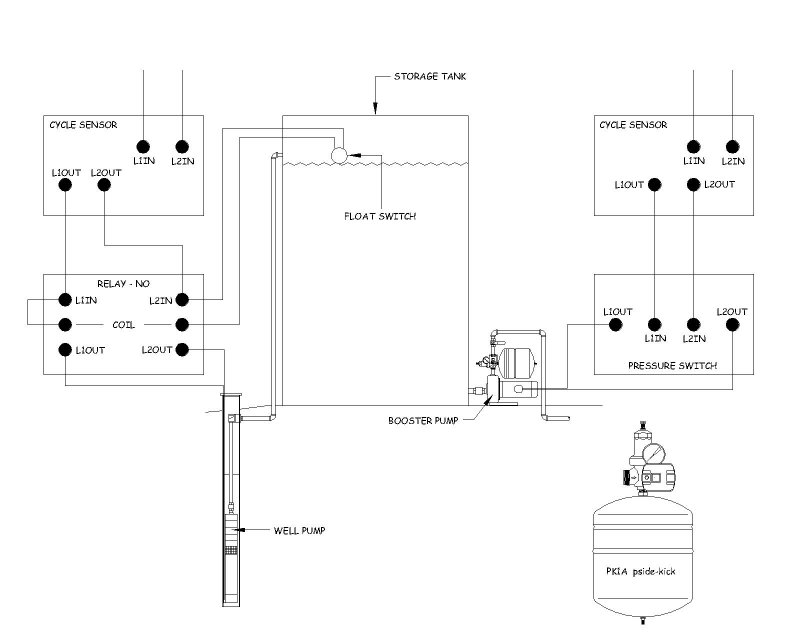

Blowing with air works great to clean up the well and screen. You can also run a camera down there to see what is happening beforehand. Worst case you let the pump produce 1 GPM or whatever it will and put that into a storage tank or cistern. Then a little booster pump in the cistern will supply as much water as the house needs. 1 GPM is still 1440 gallons per day and can supply 3-5 houses when using a cistern system.

Sponsor

Paid Advertisement

Thank you Valveman! That's about what it was doing, about 1 GPM. The well guy seemed to indicate it was hopeless. I guess he's saying that since the water we poured down the casing was filling up the casing, he's not sure what we were pumping wasn't the water we used to fill up the casing to test it. In other words, no - or very little - water is actually being pumped from the ground, just whatever we poured down the casing. I guess I could turn the pump on and let it pump to see if it gets to a point where no water is coming out of the pipe?

I'm a novice at this, let's assume it is getting a little water, would it hurt the pump to pump a big storage tank if it is only pumping 1 GPM? Seems like the pump would be pumping an awful lot and I would be concerned with overheating the pump. How large of a storage tank do you think would suffice using the method you mentioned?

I'm a novice at this, let's assume it is getting a little water, would it hurt the pump to pump a big storage tank if it is only pumping 1 GPM? Seems like the pump would be pumping an awful lot and I would be concerned with overheating the pump. How large of a storage tank do you think would suffice using the method you mentioned?

You would need to put a ball valve on the discharge of the pump and restrict it to 1 GPM. Letting the pump run wide open when it can only get 1 GPM is not good. But restricting the flow with a ball valve to 1 GPM just makes the pump think the well is so deep it can only lift 1 GPM, which is actually good for the pump and it can run that way 24/7/365 without getting hot.

Most house use about 300 gallon per day. I like to have about 3 days stored, so a 1000 gallon storage tank would be best. But if the pump can fill it fast enough, you can use a smaller storage tank.

Yeah let the pump run a while and see how much water you are getting. A camera down the well would be a good idea to start with. If you can pull the casing, you might be able to re-drill the same well and not need to permit as it is just rehabbing the same well?

Most house use about 300 gallon per day. I like to have about 3 days stored, so a 1000 gallon storage tank would be best. But if the pump can fill it fast enough, you can use a smaller storage tank.

Yeah let the pump run a while and see how much water you are getting. A camera down the well would be a good idea to start with. If you can pull the casing, you might be able to re-drill the same well and not need to permit as it is just rehabbing the same well?

Okay, I tried the well again today, it wasn't even a gallon a minute and what was coming out was really muddy and the color of chocolate milk. I spoke to some local well men who have been working on wells around here for many,many decades. They said they've had *some* luck with attaching an air compressor to 3/4" pvc piping and running it down the well. They tell me to let it sit with air "bubbling" in the well for some time to see if that will help break up the sentiment and clean the screen. My thoughts were to try the air compressor method. Once complete, pour two to three gallons of white vinegar down the well and cap the casing for a few days. My hopes are that some pressure will build in the casing and the vinegar will be forced in to the screen and open it up. Once a few days are complete, perform the air compressor trick again. Does anyone see an issue with this method?

1. What CFM is the compressor? If it is an electric-powered compressor, I would be consider using an air lift pump to lift solids out of the well. If it is a big engine-powered compressor, there are other options. Read up, and see what you think.Okay, I tried the well again today, it wasn't even a gallon a minute and what was coming out was really muddy and the color of chocolate milk. I spoke to some local well men who have been working on wells around here for many,many decades. They said they've had *some* luck with attaching an air compressor to 3/4" pvc piping and running it down the well. They tell me to let it sit with air "bubbling" in the well for some time to see if that will help break up the sentiment and clean the screen. My thoughts were to try the air compressor method. Once complete, pour two to three gallons of white vinegar down the well and cap the casing for a few days. My hopes are that some pressure will build in the casing and the vinegar will be forced in to the screen and open it up. Once a few days are complete, perform the air compressor trick again. Does anyone see an issue with this method?

2. I am not saying the bubbling method won't help. But how does it get the water out? Maybe the whole thing can be thought of as an air lift pump and mud will bubble out with the air bubbles. The more I think of it, the better that sounds. What kind of pipe were you thinking of putting down there? Take pictures.

3. Vinegar is a really mild acid for what you propose.

1. What CFM is the compressor? If it is an electric-powered compressor, I would be consider using an air lift pump to lift solids out of the well. If it is a big engine-powered compressor, there are other options. Read up, and see what you think.

2. I am not saying the bubbling method won't help. But how does it get the water out? Maybe the whole thing can be thought of as an air lift pump and mud will bubble out with the air bubbles. The more I think of it, the better that sounds. What kind of pipe were you thinking of putting down there? Take pictures.

3. Vinegar is a really mild acid for what you propose.

That's what is interesting, both of the guys told me the size and CFM really doesn't matter. One - who has been doing wells since the '70s - said he just uses a horse and a half compressor that he carries around in his truck. They both said the same thing, don't have your face over the casing and one told me that I'll probably have to weigh down the pipe or it will attempt to try and lift out of the casing. I don't completely understand the physics behind it, but they both independently said the same thing.

Concerning a large compressor, someone mentioned to me that I would need a 300 CFM, pull behind compressor and a cap would need to be welded to the casing (it's galvanized) and an air coupling in the welded cap. I mentioned this to one of the well guys and he said that might be necessary to "initialize" a new well, but to rejuvenate an existing well it is not necessary.

Both guys said just 3/4" schedule 40. It's open at the bottom so it's really not under pressure. The well bottom is 96 feet. One told me to get close to the bottom and the other said make sure I'm at least 50 feet down.

The vinegar idea I got from this post: https://terrylove.com/forums/index.php?threads/sand-point-well-low-yield.63326/

I was planning on using the Nuwell pills but after reading that post, I was thinking I would just try the vinegar trick.

LLigetfa

DIYer, not in the trades

A pressure washer with a sewer jetting nozzle might clean the screen and is not difficult to do. Of course you need a supply of water for the pressure washer.

Read up on air lift pumps.That's what is interesting, both of the guys told me the size and CFM really doesn't matter. One - who has been doing wells since the '70s - said he just uses a horse and a half compressor that he carries around in his truck. They both said the same thing, don't have your face over the casing and one told me that I'll probably have to weigh down the pipe or it will attempt to try and lift out of the casing. I don't completely understand the physics behind it, but they both independently said the same thing.

With a 275 or so cfm compressor, you can put a 1 inch pipe down a 5 inch well. Blow, and crud and water come flying out like a geyser erupting.Concerning a large compressor, someone mentioned to me that I would need a 300 CFM, pull behind compressor and a cap would need to be welded to the casing (it's galvanized) and an air coupling in the welded cap. I mentioned this to one of the well guys and he said that might be necessary to "initialize" a new well, but to rejuvenate an existing well it is not necessary.

The lower CFM method will not be so spectacular , but since you are not paying hundreds of dollars per day to rent the compressor, so what if it takes a while? I am thinking maybe 8 cfm would be good.

I am not sure what pipe I would stick down a 2 inch well. Glued 3/4 pvc? You would have to make sure the glue was dry. 1 inch poly, perhaps with a stick of galvanized on the bottom? Would the well casing restrain the poly, and prevent it from doubling back?

For holding the pipe down, maybe use a ratchet strap strapped to a vehicle up top.

I have no relevant experience.

Bannerman

Well-Known Member

As stated in the OP, it seems they intend to pressurize the 2" casing so the compressed air flowing through the screened area will dislodge any debris that has collected within the screen slots to push the debris back into the surrounding soil.

I suspect the vinegar pre-treatment soak is intended to dissolve/soften any minerals that may be dissolved by acid so the compressed air treatment will be more likely to dislodge the debris. One benefit to vinegar is it being food-grade so less likely to result in a safety concern in case there is any residue afterwards.

Regular vinegar is 5-6% acetic acid whereas pickling vinegar is 18-20% acetic acid which may be more effective in anticipation of some dilution from water continuing to enter the casing prior to pressurization. Using pickling vinegar will require more thorough flushing afterwards compared to regular vinegar.

I suspect the vinegar pre-treatment soak is intended to dissolve/soften any minerals that may be dissolved by acid so the compressed air treatment will be more likely to dislodge the debris. One benefit to vinegar is it being food-grade so less likely to result in a safety concern in case there is any residue afterwards.

Regular vinegar is 5-6% acetic acid whereas pickling vinegar is 18-20% acetic acid which may be more effective in anticipation of some dilution from water continuing to enter the casing prior to pressurization. Using pickling vinegar will require more thorough flushing afterwards compared to regular vinegar.

Last edited:

I see. That sounds like that would be trying to drive the mud into the aquifer through the screen, rather than trying to remove the sediment.As stated in the OP, it seems they intend to pressurize the 2" casing so the compressed air flowing through the screened area will dislodge any debris that has collected within the screen slots to push the debris back into the surrounding soil.

That's the value of the Nuwell pills I suppose, the pills rapidly fall to the bottom of the well where they dissolve against the casing and I suspect have a better chance of dissolving any minerals in the screen. However, vinegar is more dense than water alone so pouring liquid vinegar down the casing should have a similar effect. I can buy an awful lot of liquid vinegar for the $80 price of the Nuwell pills.

I would be very surprised if the vinegar would fall to the bottom, rather than mixing with the water.However, vinegar is more dense than water alone so pouring liquid vinegar down the casing should have a similar effect.

I would be very surprised if the vinegar would fall to the bottom, rather than mixing with the water.

Been reading today, some say use chlorine and dry ice? These guys on Facebook have videos that show good results with dry ice: https://www.facebook.com/watch/Mullis-Well-Drilling-Grading-1419707978040992/

Tried lots of things over the years. Never had any luck with dry ice. Only used vinegar to lower the PH before adding Chlorine. Best of luck though, won't hurt to try. Dry ice will build enough pressure to blow the well cap off, so be careful.

Okay, setting up the storage set up and have a few questions:

1) I can't find any images of a storage tank/aerator setup to help me. Where do I pull the voltage to run the booster pump? I have 10/2 UF running to the vertical pump. Do I just tap that and run a leg over to the booster?

2) What booster pump is acceptable? I have a flotec fp4112-08, would that work?

3) I currently have a 40 gallon pressure tank for the vertical. From the image Valveman provided (thanks again Valveman), it looks like I replace that tank with a small pressure tank on the booster pump side. Trying to save money around Christmas, I have a small pressure tank but neither. How do you set the pressure on a the tank and booster pump? Same as the vertical and 40 gallon tank? I guess I'm locking up on when the building calls for water, the booster comes on and pumps and builds pressure in the small tank. Doesn't the booster pump cycle all the time with such a small tank? I guess I'm locking up on the particular of the setup.

1) I can't find any images of a storage tank/aerator setup to help me. Where do I pull the voltage to run the booster pump? I have 10/2 UF running to the vertical pump. Do I just tap that and run a leg over to the booster?

2) What booster pump is acceptable? I have a flotec fp4112-08, would that work?

3) I currently have a 40 gallon pressure tank for the vertical. From the image Valveman provided (thanks again Valveman), it looks like I replace that tank with a small pressure tank on the booster pump side. Trying to save money around Christmas, I have a small pressure tank but neither. How do you set the pressure on a the tank and booster pump? Same as the vertical and 40 gallon tank? I guess I'm locking up on when the building calls for water, the booster comes on and pumps and builds pressure in the small tank. Doesn't the booster pump cycle all the time with such a small tank? I guess I'm locking up on the particular of the setup.

The booster pump will cycle all the time no matter what size tank you have. Larger tanks just reduce the number of cycles somewhat. Adding a Cycle Stop Valve with any size tank will stop the cycling. With the CSV you only need a small tank, but it will work fine with any size tank. Since you already have a tank, switch, etc, you don't need the kit, just the CSV1A valve.

Just make a nozzle to spray water into the storage tank when the well pump is filling it. That will aerate the water in the storage tank. Then yes your Flotec pump will work with the CSV, tank and switch, and looks like it can be set to 40/60 if you want.

It will look just like the drawing in post #2.

Just make a nozzle to spray water into the storage tank when the well pump is filling it. That will aerate the water in the storage tank. Then yes your Flotec pump will work with the CSV, tank and switch, and looks like it can be set to 40/60 if you want.

It will look just like the drawing in post #2.

Thanks again Valveman. One last question, do I tap the current 10/2 wire to run the booster? I was once told never tap the wire to the pump - even for a light - since you might damage the pump by pulling off power from the wire. I have a 30amp breaker, just concerned the breaker might not be able to handle the vertical and booster cycling at the same time.

Number 10 wire can handle a 2HP load up to 390'. That would also handle two, 1HP loads for that distance.

One last question, would I need a subpanel so I will have two breakers for the pumps? I was just going to use a weather proof conduit box and tie the 10/2 from the main panel to one run of 12/2 for the vertical pump and one run of 12/2 for the booster. In essence, pigtail three hots together, pigtail the other leg of hots together and tie the three grounds together and tie them to ground. However, someone mentioned to me that it is required that I put in a subpanel- without a main breaker in the subpanel - and have a 15 amp breaker for each of the pumps.

Similar threads

- Replies

- 2

- Views

- 426

- Replies

- 3

- Views

- 477

- Replies

- 15

- Views

- 583

- Replies

- 5

- Views

- 313