Gustave

Member

Hello,

This is my first post. My wife and bought 10 acres in Paso Robles CA. We are now building a house.

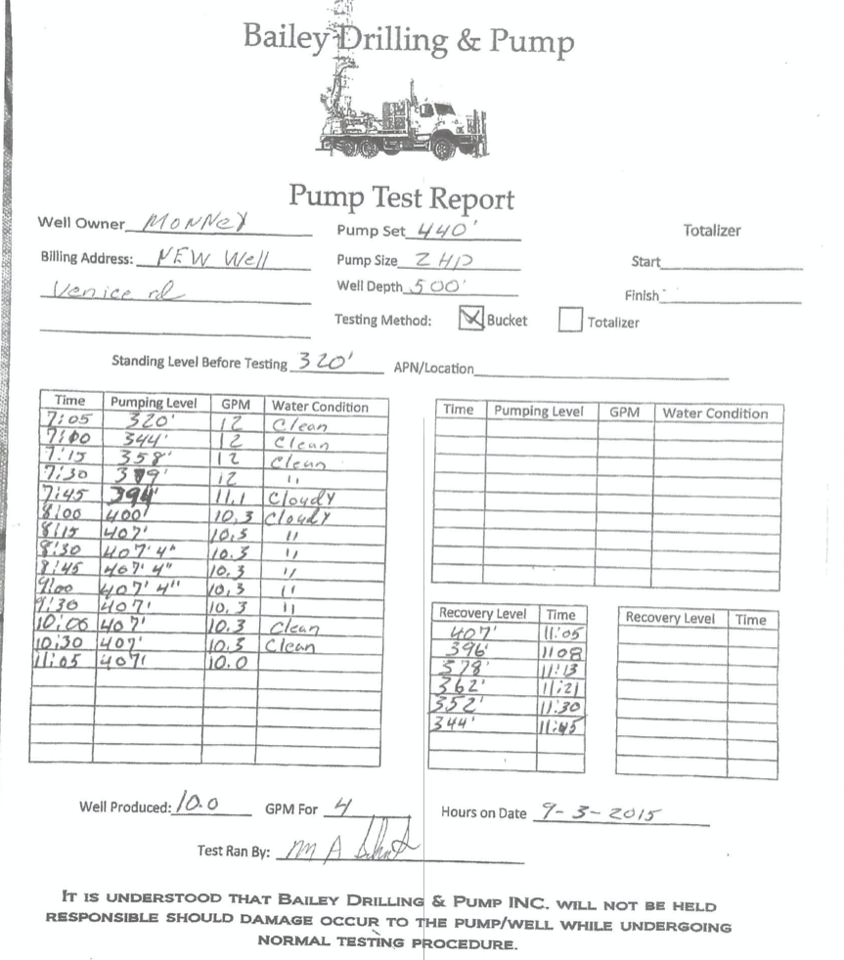

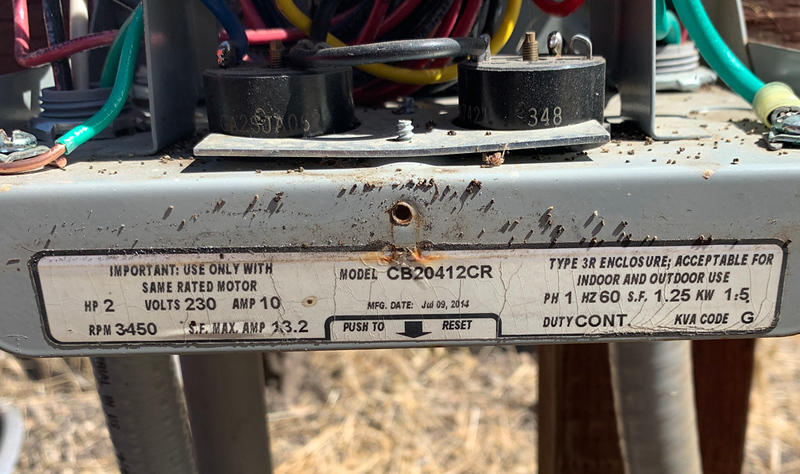

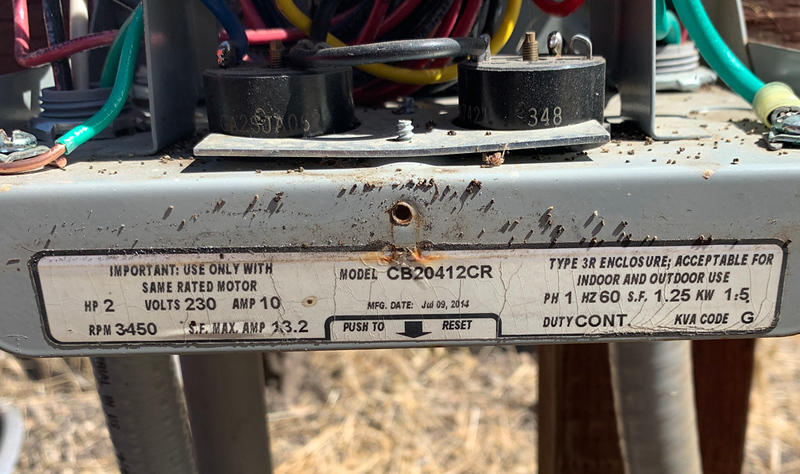

The property came with a well and pump. The well report says the well is 500 ft deep and produces 10 GPM. I don't know anything about the pump, but the installed pump controller is limited to 2 HP. So I assume the pump is less than that.

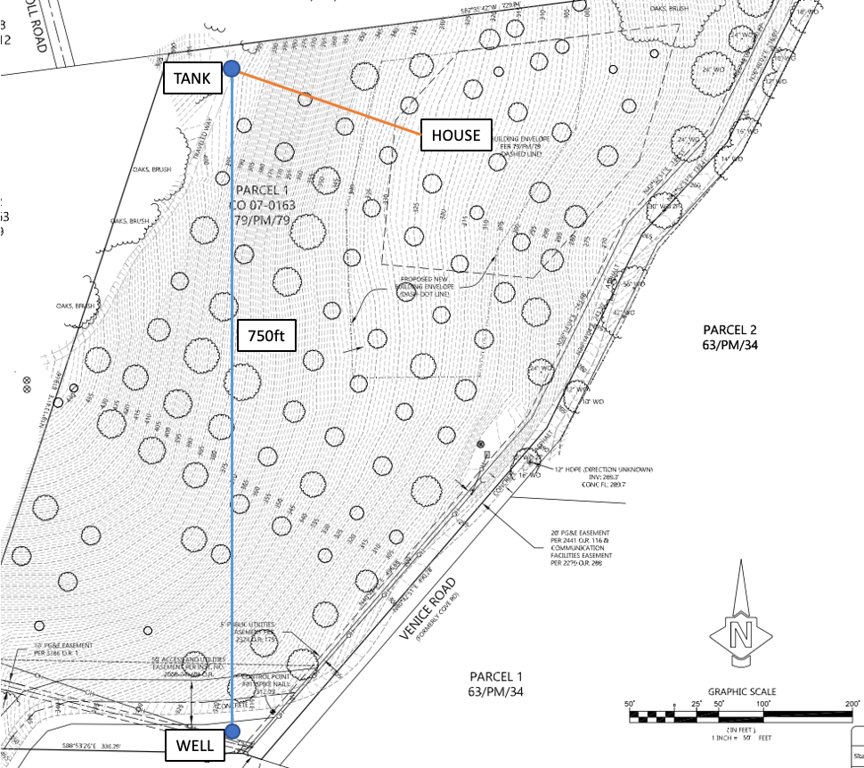

We have installed a 10,000 gal galvanized tank on the hill behind the house, as per Cal Fire Code. It is 80 ft higher in elevation than the top of the well. I am about to dig a trench to lay pipe from the well to the tank. I am debating between 1-1/2" or 2" PVC.

At 8-10 GPM I am not sure if the friction will really be all that different. And I'm not sure if there are other considerations.

Any advice would be appreciated. Thank you.

Gustave

This is my first post. My wife and bought 10 acres in Paso Robles CA. We are now building a house.

The property came with a well and pump. The well report says the well is 500 ft deep and produces 10 GPM. I don't know anything about the pump, but the installed pump controller is limited to 2 HP. So I assume the pump is less than that.

We have installed a 10,000 gal galvanized tank on the hill behind the house, as per Cal Fire Code. It is 80 ft higher in elevation than the top of the well. I am about to dig a trench to lay pipe from the well to the tank. I am debating between 1-1/2" or 2" PVC.

At 8-10 GPM I am not sure if the friction will really be all that different. And I'm not sure if there are other considerations.

Any advice would be appreciated. Thank you.

Gustave