extendofox

New Member

Good day,

My property is a small farm compound with 2 homes serviced by a central well + cistern. the well was 100' when drilled in 1978 and made 100 gpm according to records. it was originally set up with a windmill to pump into the 1500 gal. cistern. The windmill was replaced at some point with a submersible pump and there is a jet pump atop the cistern pumping to a pressure tank that distributes to both residences.

Last summer, the well dried up, and was deepened to 300' which yielded 45 gpm according to the driller.(hooray). while waiting for the drilling, we bought 3 2500 gallon plastic storage tanks for water, and filled them by truck. This capacity made sense for us because the water trucks charge the same amount whether or not you can take all of their water and they can hold 5,000 gallons. So the 7500 gallon capacity allowed us to have 2500 gallons extra while we wated for the next truck. Our water needs were high at the time with our farm operations. The procedure was just to gravity feed from the 2500's into the cistern periodically to feed the jet pump. Since the well has been deepened, the 3 storage tanks are just sitting full. We would like to condemn the old concrete cistern, which is impossible to clean well because of cracks and crevices which hold onto a lot of slimy IRB and other grime. I like the idea of keeping the storage tanks hooked into the system, for fire fighting capability and such.

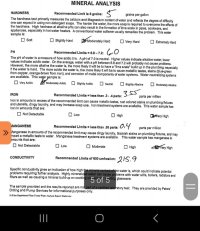

The well is high in ferrous Iron and Manganese and the iron reducing bacteria lives in the cistern and pipes. PH is 6.0.

My thinking is to set up a system to raise PH and precipitate iron in an aeration tank, filter with backwashing filter and possibly some big blue filters and then to storage tanks for holding and distribution. I like the idea of setting up a system that will not require the use of chemicals. Softened water is not good for plants.

more about current setup:

house 1 is at the lowest point in elevation, about 10' lower in elevation than the well head. the cistern, jet pump and storage tanks are all about 30' higher than the well head. House 2 is 15' higher than that, at the highest elevation point of the system. the jet pump is on a 40/60 switch which gives house 1 about 80 psi and house 2 about 50 psi. The 3/4 hp well pump was replaced before deepening the well in the hope that it was just the pump going bad. after deepening the well from 100' to 300', the same new pump was used, which makes about 4 gpm at the cistern when the static water level in the well is at maximum.

My idea:

The well pump is a bit underpowered, as it can only make 4 gpm when the well is full static water level is about 180' above the pump. To help with this, we will

move one 2500 gallon tank to the well head as an aeration/settling tank. this is 30' lower in elevation than the cistern so it should help and we can possibly use the currwnt well pump for a few years atleast until drought worsens and the static well level drops further.

install a venturi air port before a kind of spray nozzle to put aerated and disturbed water into the tank. hopefully this will raise the ph to 7.0 and most of the Ferrous iron will come out of solution in this tank. From here a small pump will send the water through a backwashing filter and in-pipe UV sanitizer and up to the storage tanks and distribution pump 30' up hill.

what are your thoughts on this plan? what would be the best way to treat the IRB in the aeration/settling tank? what is the best backwashing filter for iron/manganese?

Thanks

My property is a small farm compound with 2 homes serviced by a central well + cistern. the well was 100' when drilled in 1978 and made 100 gpm according to records. it was originally set up with a windmill to pump into the 1500 gal. cistern. The windmill was replaced at some point with a submersible pump and there is a jet pump atop the cistern pumping to a pressure tank that distributes to both residences.

Last summer, the well dried up, and was deepened to 300' which yielded 45 gpm according to the driller.(hooray). while waiting for the drilling, we bought 3 2500 gallon plastic storage tanks for water, and filled them by truck. This capacity made sense for us because the water trucks charge the same amount whether or not you can take all of their water and they can hold 5,000 gallons. So the 7500 gallon capacity allowed us to have 2500 gallons extra while we wated for the next truck. Our water needs were high at the time with our farm operations. The procedure was just to gravity feed from the 2500's into the cistern periodically to feed the jet pump. Since the well has been deepened, the 3 storage tanks are just sitting full. We would like to condemn the old concrete cistern, which is impossible to clean well because of cracks and crevices which hold onto a lot of slimy IRB and other grime. I like the idea of keeping the storage tanks hooked into the system, for fire fighting capability and such.

The well is high in ferrous Iron and Manganese and the iron reducing bacteria lives in the cistern and pipes. PH is 6.0.

My thinking is to set up a system to raise PH and precipitate iron in an aeration tank, filter with backwashing filter and possibly some big blue filters and then to storage tanks for holding and distribution. I like the idea of setting up a system that will not require the use of chemicals. Softened water is not good for plants.

more about current setup:

house 1 is at the lowest point in elevation, about 10' lower in elevation than the well head. the cistern, jet pump and storage tanks are all about 30' higher than the well head. House 2 is 15' higher than that, at the highest elevation point of the system. the jet pump is on a 40/60 switch which gives house 1 about 80 psi and house 2 about 50 psi. The 3/4 hp well pump was replaced before deepening the well in the hope that it was just the pump going bad. after deepening the well from 100' to 300', the same new pump was used, which makes about 4 gpm at the cistern when the static water level in the well is at maximum.

My idea:

The well pump is a bit underpowered, as it can only make 4 gpm when the well is full static water level is about 180' above the pump. To help with this, we will

move one 2500 gallon tank to the well head as an aeration/settling tank. this is 30' lower in elevation than the cistern so it should help and we can possibly use the currwnt well pump for a few years atleast until drought worsens and the static well level drops further.

install a venturi air port before a kind of spray nozzle to put aerated and disturbed water into the tank. hopefully this will raise the ph to 7.0 and most of the Ferrous iron will come out of solution in this tank. From here a small pump will send the water through a backwashing filter and in-pipe UV sanitizer and up to the storage tanks and distribution pump 30' up hill.

what are your thoughts on this plan? what would be the best way to treat the IRB in the aeration/settling tank? what is the best backwashing filter for iron/manganese?

Thanks