LLigetfa

DIYer, not in the trades

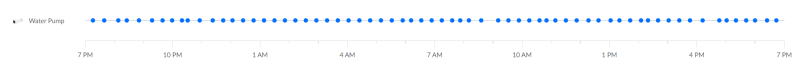

I've noticed that my pump is running frequently when there is no obvious use of water. I have a camera on the pressure switch to record when the pump turns on and off. Here is the frequency over the last 24 hours.

Seeing that the time between cycles over the last few days varies considerably, my guess is that the loss of water is due to a failing check valve. I've seen as much as two hours pass between pump cycles and at other times just 20 minutes. I think a hole in a fitting or leaking O-ring on the pitless would leak at a consistent rate whereas the poppet in the check valve moves around and could seat better on one cycle than the other.

Of course Murphy's Law states that bad things happen at the worst time, and I have booked some vacation time and company is coming to visit. I am hoping not to ask my visitors to help me pull the pump to add a check valve on top of the pump and that I can get away with installing a check valve where the water line comes into the house for now. Of course Murphy could conspire against me and it is a leak between the well casing and the house and adding a check valve risks surface water getting into the supply and I make my guests sick with bad water.

Seeing that the time between cycles over the last few days varies considerably, my guess is that the loss of water is due to a failing check valve. I've seen as much as two hours pass between pump cycles and at other times just 20 minutes. I think a hole in a fitting or leaking O-ring on the pitless would leak at a consistent rate whereas the poppet in the check valve moves around and could seat better on one cycle than the other.

Of course Murphy's Law states that bad things happen at the worst time, and I have booked some vacation time and company is coming to visit. I am hoping not to ask my visitors to help me pull the pump to add a check valve on top of the pump and that I can get away with installing a check valve where the water line comes into the house for now. Of course Murphy could conspire against me and it is a leak between the well casing and the house and adding a check valve risks surface water getting into the supply and I make my guests sick with bad water.