The flex plumbing lines are the most common way and easier way to connect from a stop valve to a toilet or faucet. However the chrome-plated nearly-rigid "copper riser" lines are not as hard as I used to think... but I admit to having not yet attempted one. I am looking forward to trying if I ever replace at toilet fill valve in the future. If somebody notes some error for me to correct or suggest a good improvement, I will edit this. This is also my first "resource" posting. I am not a plumber.

The advantages include they look cool. They are least likely to fail. They have no rubber liner to decompose.

To remove them, I think you will need to cut the existing line. That is because the ferrule/sleeve/olive will be compressed hard to the line. A new one is readily available, however.

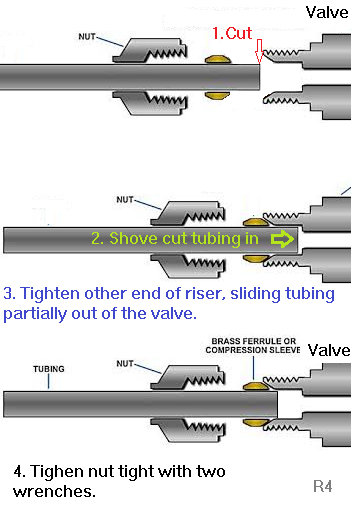

The Compress_rigid.png picture illustrates:

1. The line will start too long. Hold the new riser to the toilet or faucet and mark where to cut. The nuts and ferrule can be in place before you cut, or could be put on after the cut if you dress up the cut end.

2. After the cut, shove that cut end into the compression valve until it stops.

3. Tighten the top of the riser to the toilet fill valve or the lavatory valve. The riser will come part way out of the valve, but enough will stay inside.

4. Tighten the compression nut, using one wrench on the nut, and one on the valve body. It takes a lot of torque. Sometimes it is better to lube the ferrule with pipe dope or silicone grease. Similarly you can lightly lube the threads. That reduces the friction, and therefore the torque that you must apply. I don't think you can over-torque with small wrenches. I can't.

The advantages include they look cool. They are least likely to fail. They have no rubber liner to decompose.

To remove them, I think you will need to cut the existing line. That is because the ferrule/sleeve/olive will be compressed hard to the line. A new one is readily available, however.

The Compress_rigid.png picture illustrates:

1. The line will start too long. Hold the new riser to the toilet or faucet and mark where to cut. The nuts and ferrule can be in place before you cut, or could be put on after the cut if you dress up the cut end.

2. After the cut, shove that cut end into the compression valve until it stops.

3. Tighten the top of the riser to the toilet fill valve or the lavatory valve. The riser will come part way out of the valve, but enough will stay inside.

4. Tighten the compression nut, using one wrench on the nut, and one on the valve body. It takes a lot of torque. Sometimes it is better to lube the ferrule with pipe dope or silicone grease. Similarly you can lightly lube the threads. That reduces the friction, and therefore the torque that you must apply. I don't think you can over-torque with small wrenches. I can't.