Blue Oaks

Member

Guys,

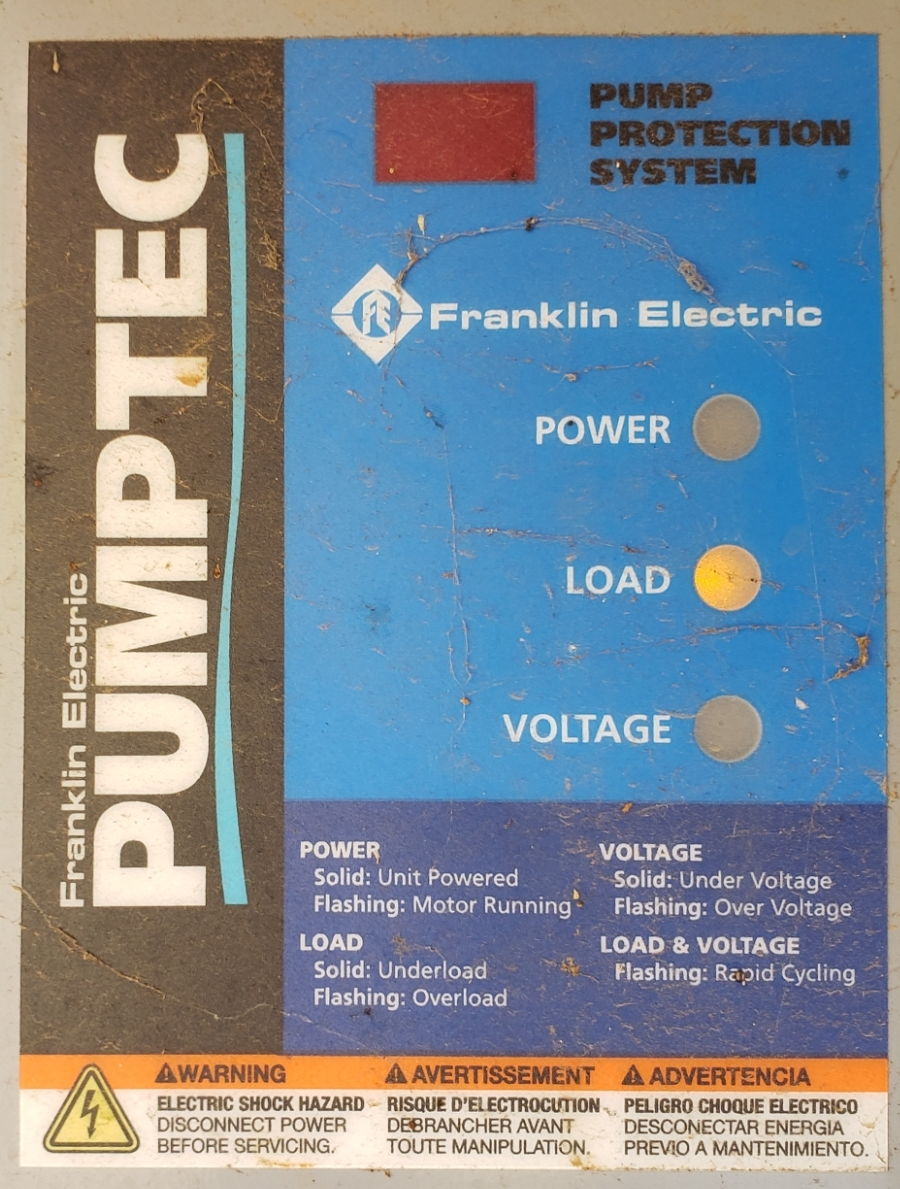

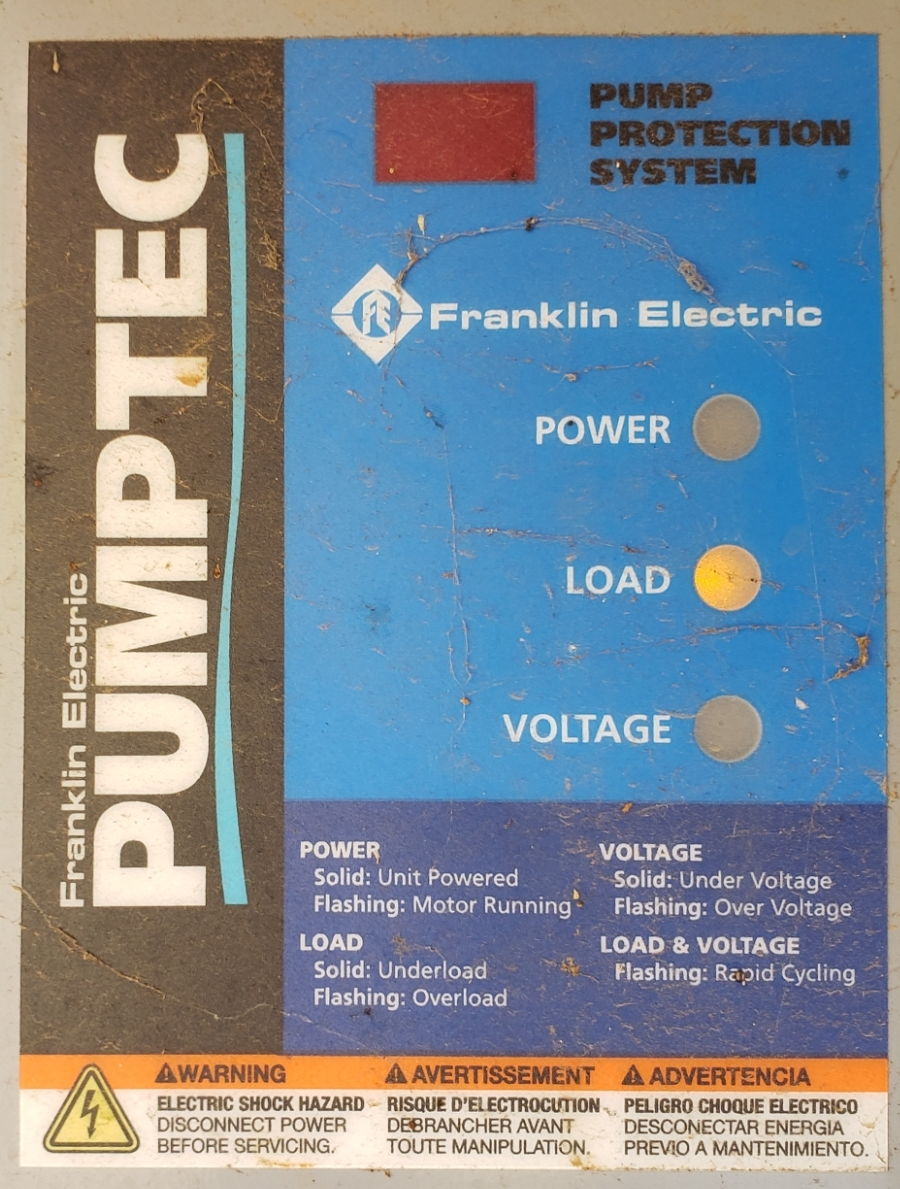

I've noticed my water level gauge going lower over the past few days, which is unusual for this time of year. If you recall I have a couple of tanks way up on the hill behind my house. The pump house is below my house and has a PUMPTEC controller.

I went down and observed the controller for a while and didn't see the light move from LOAD to POWER. Typical operation is the LOAD (yellow) light is solid / illuminated when there isn't enough water in the storage tanks, and the tank float switch is closed (asking for water). I turned the power off to the system for a few seconds and turned it back on. The POWER (green) light flashed once per second for about 5 seconds, then it reverted back to solid LOAD.

Typically the LOAD light stays lit for five to ten minutes, then the POWER light flashes for 3-5 minutes as the well pumps. Is my pump fried? I think it's unlikely the well has run dry following historic rains and no one in the neighborhood is pumping much water from their wells.

I've got the local well guy coming out tomorrow to take a look, but thought I'd ping y'all for opinions in the meantime.

Andy

I've noticed my water level gauge going lower over the past few days, which is unusual for this time of year. If you recall I have a couple of tanks way up on the hill behind my house. The pump house is below my house and has a PUMPTEC controller.

I went down and observed the controller for a while and didn't see the light move from LOAD to POWER. Typical operation is the LOAD (yellow) light is solid / illuminated when there isn't enough water in the storage tanks, and the tank float switch is closed (asking for water). I turned the power off to the system for a few seconds and turned it back on. The POWER (green) light flashed once per second for about 5 seconds, then it reverted back to solid LOAD.

Typically the LOAD light stays lit for five to ten minutes, then the POWER light flashes for 3-5 minutes as the well pumps. Is my pump fried? I think it's unlikely the well has run dry following historic rains and no one in the neighborhood is pumping much water from their wells.

I've got the local well guy coming out tomorrow to take a look, but thought I'd ping y'all for opinions in the meantime.

Andy