Threehappypenguins

Member

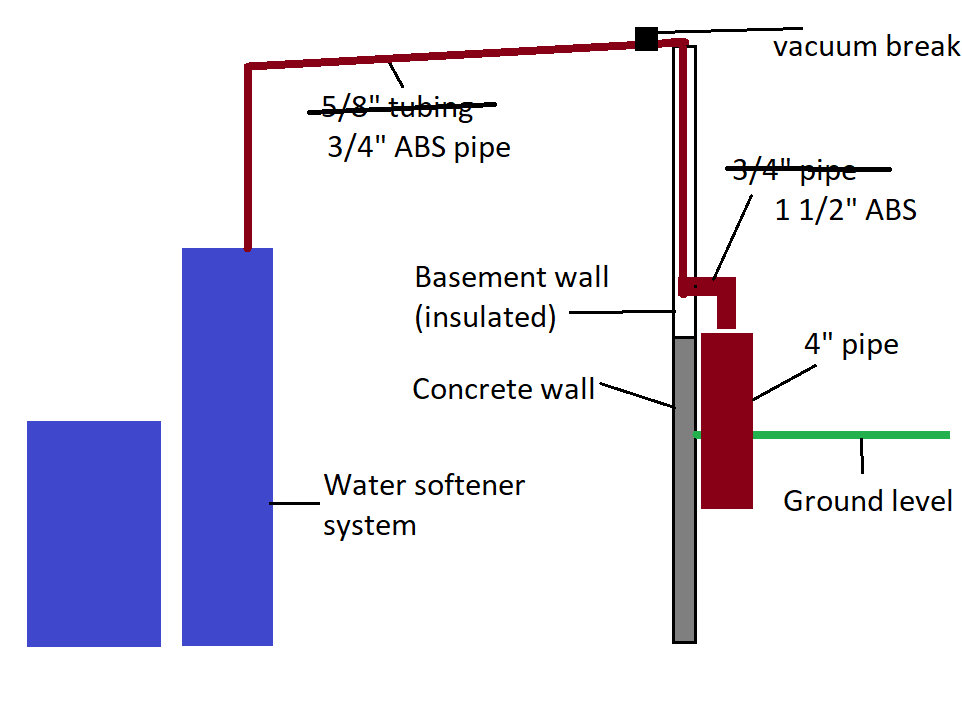

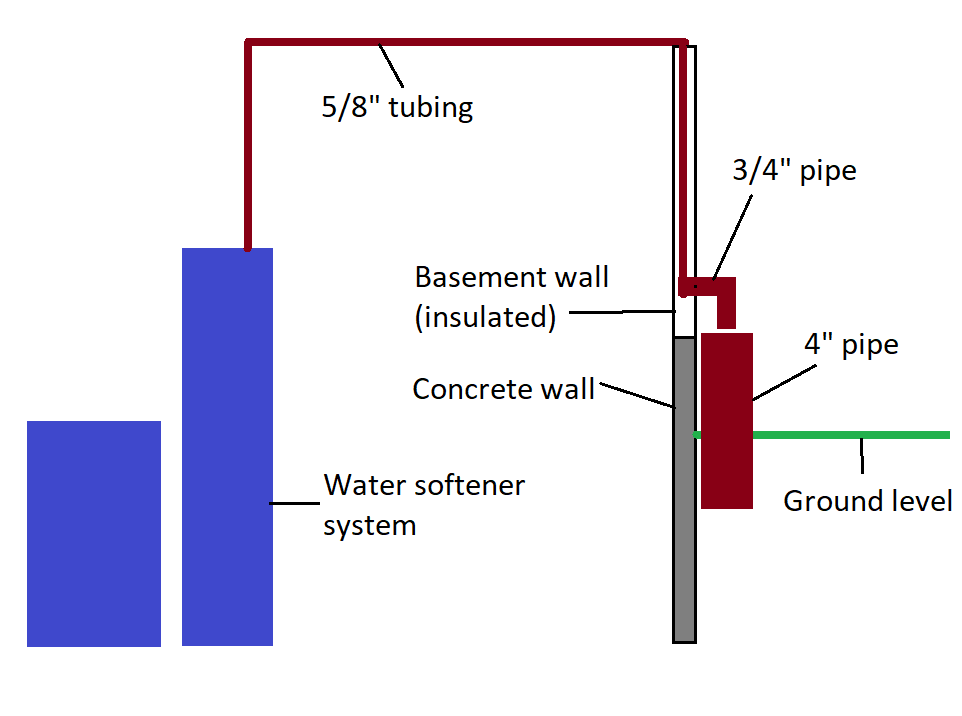

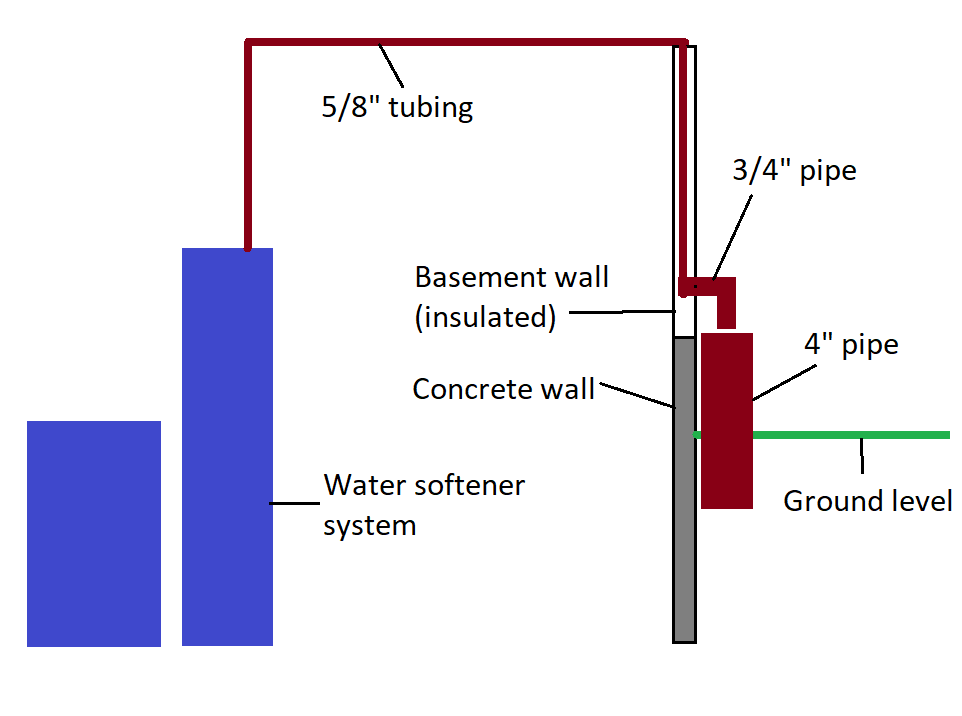

We had two "water specialists" come by today because we wanted to hear what their plans were with regards to water softener setup and backwash. We already decided that we absolutely will not permit the backwash to be tied into our (very small) septic system. We will likely do the work ourselves (have enough experience). For clarity, I created this graphic to try and explain what they want to do:

We have a 1986 split entry home where our basement is only about halfway into the ground (the kind with the pony walls throughout). We live in Nova Scotia, where we do get freezing weather in the winter, but usually it hovers around 0 C most of the winter, sometimes dipping to -10 C, and very rarely more than -20 C. The frost line is usually about 3 ft below ground, but every so often (very rarely) we get a deep freeze where the frost line is like 5 feet down (happened a few years ago and some people had an issue with their septic tanks freezing).

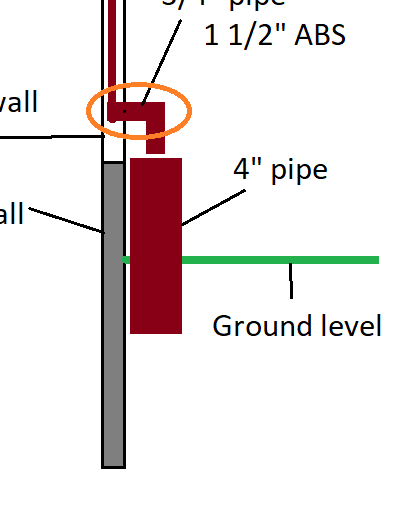

The first guy wants to go from the tubing to 3/4" drainage pipe, and then have that come out our wall just above the concrete, and point down toward a 4" sewer pipe (they would not actually be connected, so there would be an air gap. Then the sewer pipe go a couple of feet below ground, turn to the right, and run paralell to the house, past it about 4' and to an underground gravel pit (but not an actual dry well).

The second guy pretty much wants to do the same thing, only from the tubing to a 1 1/2" drainage pipe to a 3" pipe to catch the water and go under ground.

Something like this shouldn't freeze, right? Which way is better? First? Second? A combo of both? Neither? Also, is a full dry well really necessary? Or is just a bunch of gravel in its place okay? It's a huge pain to dig in my area, as it's very rocky and you end up pulling up a ton of boulders and big rocks as you go.

We have a 1986 split entry home where our basement is only about halfway into the ground (the kind with the pony walls throughout). We live in Nova Scotia, where we do get freezing weather in the winter, but usually it hovers around 0 C most of the winter, sometimes dipping to -10 C, and very rarely more than -20 C. The frost line is usually about 3 ft below ground, but every so often (very rarely) we get a deep freeze where the frost line is like 5 feet down (happened a few years ago and some people had an issue with their septic tanks freezing).

The first guy wants to go from the tubing to 3/4" drainage pipe, and then have that come out our wall just above the concrete, and point down toward a 4" sewer pipe (they would not actually be connected, so there would be an air gap. Then the sewer pipe go a couple of feet below ground, turn to the right, and run paralell to the house, past it about 4' and to an underground gravel pit (but not an actual dry well).

The second guy pretty much wants to do the same thing, only from the tubing to a 1 1/2" drainage pipe to a 3" pipe to catch the water and go under ground.

Something like this shouldn't freeze, right? Which way is better? First? Second? A combo of both? Neither? Also, is a full dry well really necessary? Or is just a bunch of gravel in its place okay? It's a huge pain to dig in my area, as it's very rocky and you end up pulling up a ton of boulders and big rocks as you go.