Thanks Reach.

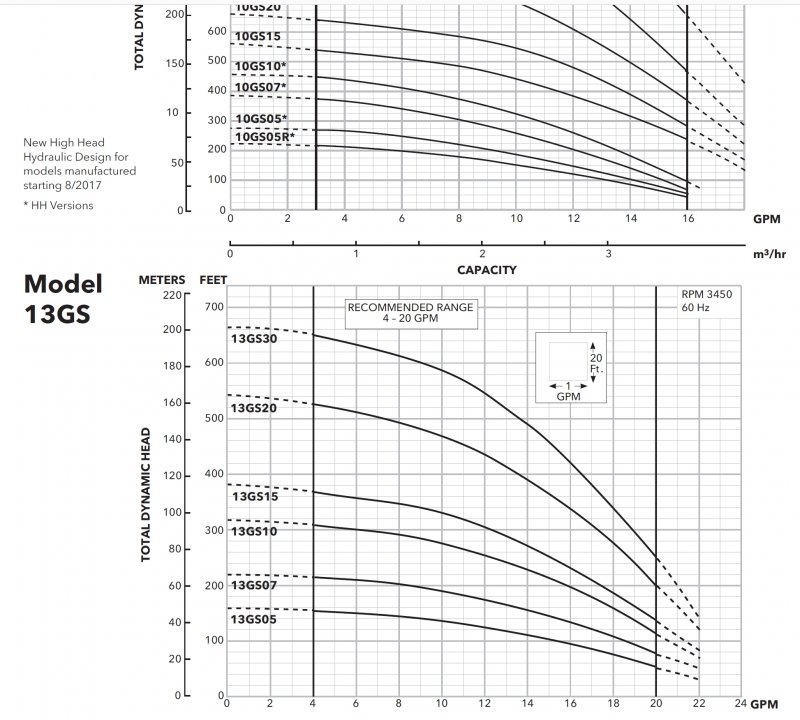

No room for flow inducer in 4" casing. I'm guess pump will be set at 40-50' based on the other well. If static is 10'-15' then pumping level may be 20'-30'? That would equal 120' TDH or so? First time looking at pump curves today.

My concern is that I plan to do a significant amount of irrigation. That is why I've gone to the expense to find better quality water. I wonder how close I can cut it on GPM. I'm getting greedy but would prefer 16 gpm over 12. If he jetted around 20 would a 13GS07 be a good pump to install?

No room for flow inducer in 4" casing. I'm guess pump will be set at 40-50' based on the other well. If static is 10'-15' then pumping level may be 20'-30'? That would equal 120' TDH or so? First time looking at pump curves today.

My concern is that I plan to do a significant amount of irrigation. That is why I've gone to the expense to find better quality water. I wonder how close I can cut it on GPM. I'm getting greedy but would prefer 16 gpm over 12. If he jetted around 20 would a 13GS07 be a good pump to install?