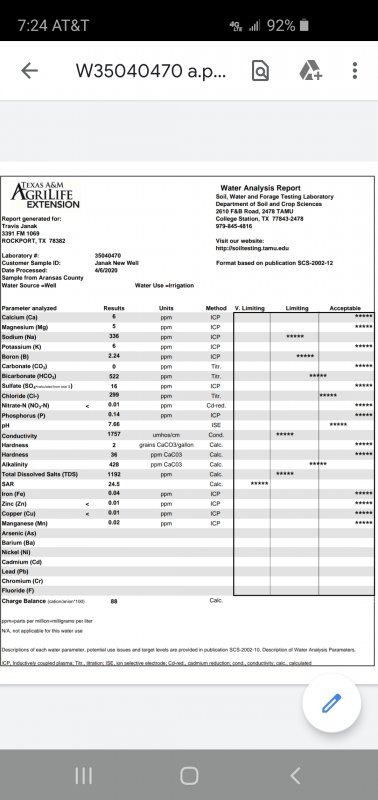

Two related questions here really. Building a house currently and had a new 4" PVC well drilled. Knew it was a gamble as to water quality and results of test are attached. I plan to retest just to be sure. Don't have the report yet from the driller but 165' deep, 1 HP pump. This thing is salty, high sodium. Boron high too, with more chloride and bicarbonates than ideal as well. Funny thing is my plumber asked how I'm going to filter the water to clean it up. Not sure why he doesn't know you can't filter out sodium, chloride, etc. RO is the only option and that won't work for irrigation! I'm considering not using this well because I'm not sure how to effectively use it. We are big landscapers, gardeners, fruit growers, and this water is effectively useless. $7500 down the drain.

About 500' from the house is a 4" PVC well of unknown age that was used for cow water. 60' deep. 1/2 HP 2 wire pump set at 50' or 55', can't remember. It has a 5 GPM choke on it. When i pull the choke out it makes plenty of water, but pumps sand. Put the choke back in, no sand. The water quality from this well is much better. I am seriously considering using it for the house, but have to deal with the sand issue. Sure I can pump into holding tanks at 5 GPM, but would need a lot of storage for lawn and garden irrigation.

Do I have any options for lining this well to screen out the sand? What would be the best route to proceed from here on making this well useable?

Thanks,

Travis

About 500' from the house is a 4" PVC well of unknown age that was used for cow water. 60' deep. 1/2 HP 2 wire pump set at 50' or 55', can't remember. It has a 5 GPM choke on it. When i pull the choke out it makes plenty of water, but pumps sand. Put the choke back in, no sand. The water quality from this well is much better. I am seriously considering using it for the house, but have to deal with the sand issue. Sure I can pump into holding tanks at 5 GPM, but would need a lot of storage for lawn and garden irrigation.

Do I have any options for lining this well to screen out the sand? What would be the best route to proceed from here on making this well useable?

Thanks,

Travis