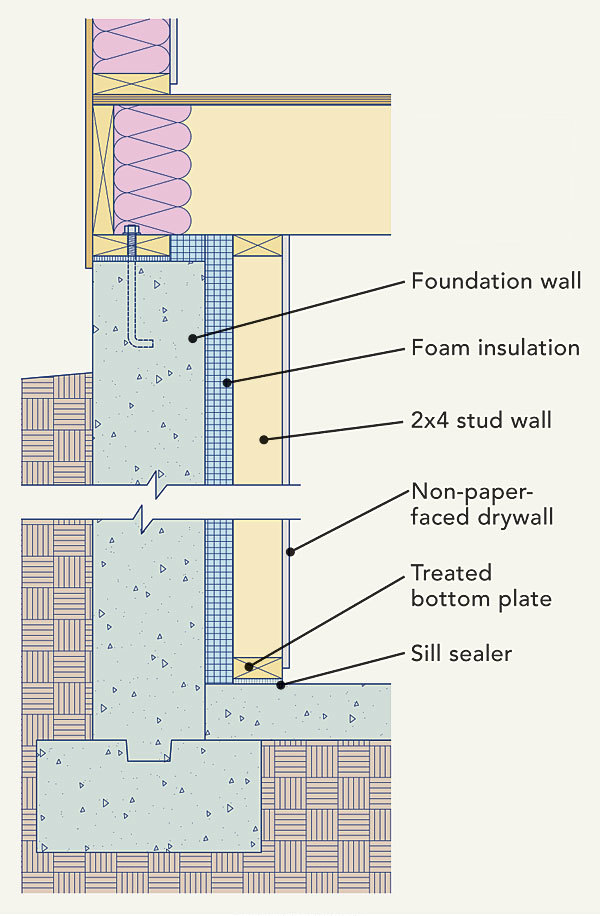

I'm working on finishing my basement. Kind of stuck on how to best frame the 1/2 wall (house has a lookout basement). I started one section, but before I go too far I thought I'd seek advice.

I've attached a picture for reference. For the section I did, I had the wall go as high as the concrete ledge. What's the best way to handle the ledge? Should I put some XPS down to insulate it, or cap it with a 2x cut to fit from the back of the ledge (tying it into the 2x6 wall) out to the edge of the framed wall? Should I lay some soldiers 4 feet apart, and use insulation in-between? Just a bit stuck on the best approach. I considered framing all the way up to eliminate the ledge, but for various reasons decided to keep the ledge.

My thought once it's framed and ready to be finished, is to use either MDF or another material to have the bottom window casing tie into the ledge itself, since there doesn't seem to be space to use any sort of trim on the bottom, give the window's proximity to the ledge. But, I'm open for ideas.

Height from floor to the concrete ledge is about 37".

Thanks.

I've attached a picture for reference. For the section I did, I had the wall go as high as the concrete ledge. What's the best way to handle the ledge? Should I put some XPS down to insulate it, or cap it with a 2x cut to fit from the back of the ledge (tying it into the 2x6 wall) out to the edge of the framed wall? Should I lay some soldiers 4 feet apart, and use insulation in-between? Just a bit stuck on the best approach. I considered framing all the way up to eliminate the ledge, but for various reasons decided to keep the ledge.

My thought once it's framed and ready to be finished, is to use either MDF or another material to have the bottom window casing tie into the ledge itself, since there doesn't seem to be space to use any sort of trim on the bottom, give the window's proximity to the ledge. But, I'm open for ideas.

Height from floor to the concrete ledge is about 37".

Thanks.