Anthony Curtas

Member

I had this as a specific "how do I lower my drain" question in the remodel forum, but after doing a lot of research today, I think I narrowed down my options to what's below.

Quick story: sink too deep, disposal outlet even with existing drain. Walls up, many cabinets already installed, don't want to lower the drain in wall for structural reasons too.

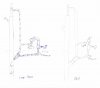

HJ quickly showed me I could not use my existing drain to tie into the vent system (too low). But after looking at island installations, I was wondering if it would work with a high loop, which I have space for. Picture below. The other option I have is simply capping the drain line and using an AAV and going through the floor of the cabinet. Both installations tie in at the basement (unfinished). I'd rather avoid the AAV, as I'm leery of anything mechanical that can fail (and have me not notice for a while). I wish I had a better option, but we already have the sink, disposal, and specialty mounting flange (and can't return them), and even a smaller disposal only buys us a 1/2" or so more height.

AAVs are allowed here (Virginia).

All advice appreciated!

Anthony

Quick story: sink too deep, disposal outlet even with existing drain. Walls up, many cabinets already installed, don't want to lower the drain in wall for structural reasons too.

HJ quickly showed me I could not use my existing drain to tie into the vent system (too low). But after looking at island installations, I was wondering if it would work with a high loop, which I have space for. Picture below. The other option I have is simply capping the drain line and using an AAV and going through the floor of the cabinet. Both installations tie in at the basement (unfinished). I'd rather avoid the AAV, as I'm leery of anything mechanical that can fail (and have me not notice for a while). I wish I had a better option, but we already have the sink, disposal, and specialty mounting flange (and can't return them), and even a smaller disposal only buys us a 1/2" or so more height.

AAVs are allowed here (Virginia).

All advice appreciated!

Anthony