You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Well Cap Stuck

- Thread starter DaveS9157

- Start date

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)

Fitter30

Well-Known Member

With a sawall cut bolts off then grind and metal left with a angle grinder. Then cut the threads off and use a well casing coupler. Use magnets to catch debris.

Sponsor

Paid Advertisement

LLigetfa

DIYer, not in the trades

If you cut those bolts off, the bottom half will likely fall down into the well and could jam so that the pump cannot be pulled, assuming there is a pump down the hole.

Daylight more of the casing to make room to zip cut the casing all the way around. That way you can weld on a new section of casing.

Daylight more of the casing to make room to zip cut the casing all the way around. That way you can weld on a new section of casing.

You must have a pitless adapter, which makes that type well seal very unusual and maybe not safe. The wore for the pump should come through the well cap like with a regular pitless well cap. If those wires go through a hole in the casing below ground, it is hard to seal and may let contamination in the well.

Don't cut those bolts or take the nuts all the way off and the bottom half and bolts can fall in the well. But if it won't budge, being that there is no wire coming through the well cap, I would sawsall off the casing about 3" below the top of the well seal. Weld on some casing to extend at least 18" above grade, and use a regular pitless well cap with a conduit connection and pull the wire through the well cap as it should be.

Don't cut those bolts or take the nuts all the way off and the bottom half and bolts can fall in the well. But if it won't budge, being that there is no wire coming through the well cap, I would sawsall off the casing about 3" below the top of the well seal. Weld on some casing to extend at least 18" above grade, and use a regular pitless well cap with a conduit connection and pull the wire through the well cap as it should be.

Fitter30

Well-Known Member

With only a 1/2"- 3/4" pipe plug in the top im thinking its only a plug. Try prying it up.If its holding the pump up how would you lift the whole assembly out.

Bannerman

Well-Known Member

The photo directly below of a removed well seal, shows a rubber bung sandwiched between the 2 larger upper metal support plates and a smaller diameter metal plate. The 4 bolts with nuts on the topside, when tightened, cause the rubber bung to be squeezed between the upper and lower plates, causing the rubber bung to expand against the inner walls of the casing, thereby preventing easy removal unless the nuts are first loosened.

As already stated, full removal of the nuts will typically allow the bolts and lower plate to drop to the bottom of the well. By simply loosening the nuts without removing them, the rubber bung and lower plate may then be pulled-up or pried out from the casing with less risk of them also falling into the well along with the bolts.

The metal plug shown threaded into the OP's upper metal plate, is often utilized for installation of a screened vent to prevent insects/rodents from entering while allowing air to enter as the water level in the well becomes lower while being pumped out, and air to exit when the water level is rising during recovery.

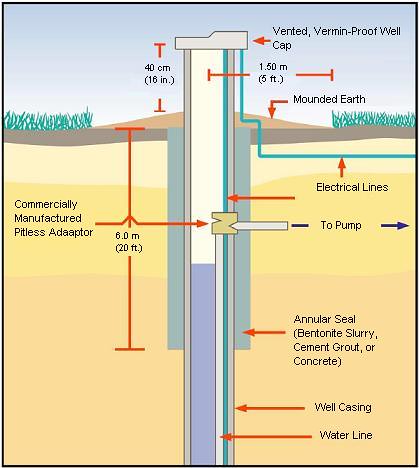

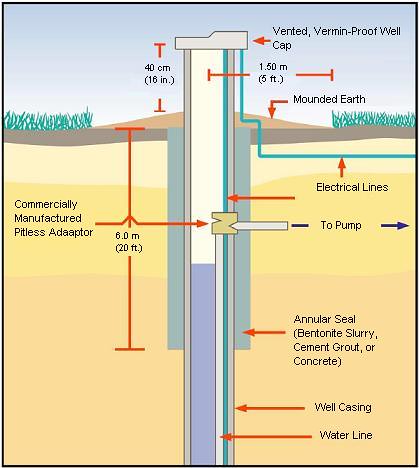

The photo below, shows a well cap commonly utilized on wells equipped with a pitless adaptor.

As already stated, full removal of the nuts will typically allow the bolts and lower plate to drop to the bottom of the well. By simply loosening the nuts without removing them, the rubber bung and lower plate may then be pulled-up or pried out from the casing with less risk of them also falling into the well along with the bolts.

The metal plug shown threaded into the OP's upper metal plate, is often utilized for installation of a screened vent to prevent insects/rodents from entering while allowing air to enter as the water level in the well becomes lower while being pumped out, and air to exit when the water level is rising during recovery.

The photo below, shows a well cap commonly utilized on wells equipped with a pitless adaptor.

YesIs that a working well?

If the pump is submersible, the wires must be currently entering below ground. Is the pump not in the well? It is possible that the well was a 2-pipe jet pump, and the wires were run thru one of the pipes when the system is was converted to use a submersible pump.

The best way to extend a steel casing is to have an extension welded on. In many places, that is the only way that is allowed.

This may be a good time to have a pitless adapter and well cap installed, with the wires as pictured in Bannerman's second and third pictures in post #6.

The best way to extend a steel casing is to have an extension welded on. If the

Various places, but those with a hole for a drop pipe are more common. However I would opt for a "well cap" instead. Seal the 1 inch conduit input. What is the casing size-- did I miss that?

A well cap can be opened easily for sanitizing.

https://www.zoro.com/search?q="well cap"

https://www.supplyhouse.com/sh/control/search/~SEARCH_STRING="well cap"

A well cap will usually have a vent built in. A well seal should have a vent added.

https://boshart.com/wp-content/uplo...2dc4d_WSP_PlasticWellSeals_technicalsheet.pdf

These are well seals with no drop pipe: https://boshart.com/product/abs-blank/

https://boshart.com/wp-content/uplo...2dc4d_WSP_PlasticWellSeals_technicalsheet.pdf

A well cap can be opened easily for sanitizing.

https://www.zoro.com/search?q="well cap"

https://www.supplyhouse.com/sh/control/search/~SEARCH_STRING="well cap"

A well cap will usually have a vent built in. A well seal should have a vent added.

https://boshart.com/wp-content/uplo...2dc4d_WSP_PlasticWellSeals_technicalsheet.pdf

These are well seals with no drop pipe: https://boshart.com/product/abs-blank/

https://boshart.com/wp-content/uplo...2dc4d_WSP_PlasticWellSeals_technicalsheet.pdf

Last edited:

Similar threads

- Replies

- 0

- Views

- 54

- Replies

- 5

- Views

- 198

- Replies

- 3

- Views

- 930

- Replies

- 16

- Views

- 437

- Replies

- 2

- Views

- 140