slowgsr

New Member

So I have a 30" precast lined dug well. Its about 55 feet deep, and there's 12 feet of water in it. I just measured, its been a very dry year. Regardless the well provides us with clean water. I'm tired of listening to the 2 line jet pump, and I'm considering having my father in law move in.

I want to have the well fill a cistern, 3000 gal, which I will excavate.

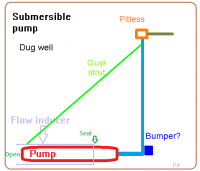

My question is, if I get a 3/4 hp submersible, build a "stand" to support the pump horizontal down a few feet from the bottom of the well, and add a low water float to prevent the pump from running dry (I could attach this to my pump fixture).

I then need to add a pitless, since it looks as if a 4" 'sleeve' goes from my well to the house, which the jet put lines go through, I don't believe they're direct burried.

Do i take my mini ex, dig on the outside of the well to the water line, then put a 2 foot stainless nipple on a pitless, and leave 6" of the pitless in the well, hydraulic cement the interior, and exterior, and just adapt some poly to the nipple on the well outside then feed it indoor through the sleeve, and I could run a multi conductor teck cable into the well up at the top where I can splice for pump power, floats etc.

Then in my pump room I can setup my CSV etc which will come from a submersible in the cistern. The well pump will just keep the cistern full.

Ill just have the well pump run off a timing system providing the cistern float is calling for water and the low level float in the well is up.

Thanks

I want to have the well fill a cistern, 3000 gal, which I will excavate.

My question is, if I get a 3/4 hp submersible, build a "stand" to support the pump horizontal down a few feet from the bottom of the well, and add a low water float to prevent the pump from running dry (I could attach this to my pump fixture).

I then need to add a pitless, since it looks as if a 4" 'sleeve' goes from my well to the house, which the jet put lines go through, I don't believe they're direct burried.

Do i take my mini ex, dig on the outside of the well to the water line, then put a 2 foot stainless nipple on a pitless, and leave 6" of the pitless in the well, hydraulic cement the interior, and exterior, and just adapt some poly to the nipple on the well outside then feed it indoor through the sleeve, and I could run a multi conductor teck cable into the well up at the top where I can splice for pump power, floats etc.

Then in my pump room I can setup my CSV etc which will come from a submersible in the cistern. The well pump will just keep the cistern full.

Ill just have the well pump run off a timing system providing the cistern float is calling for water and the low level float in the well is up.

Thanks