dieselfuelonly

New Member

So I've got my cistern set up for my low-yield well pretty much finished up, just working on the final parts of removing the old pressure switch/tank setup for the deep well pump.

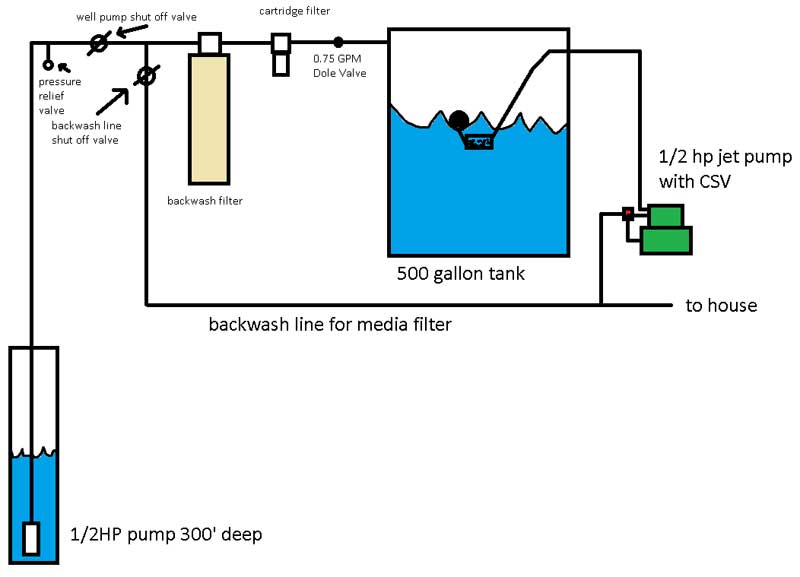

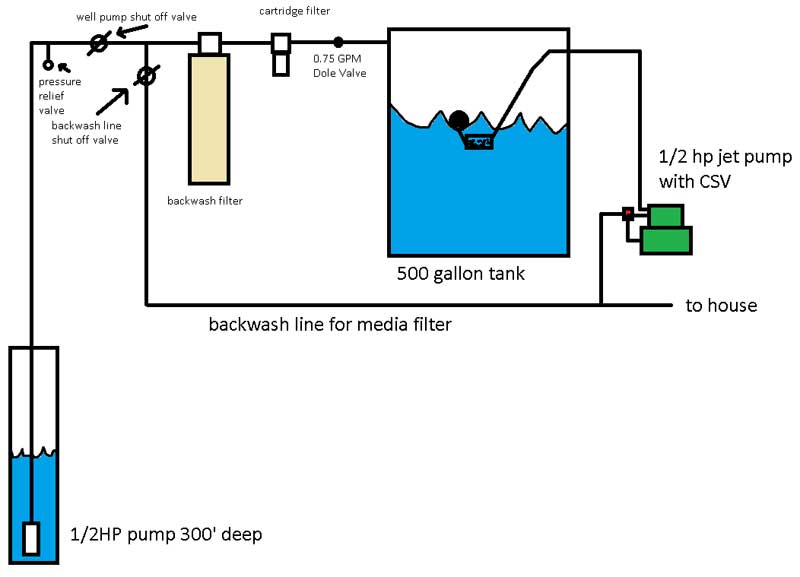

My system looks something like this (excuse my MS Paint skills)

The well has a very low recovery rate and as the water level moves up and down in it stirs up a lot of sediment. To help reduce that sediment I have set up a backwash filter and a cartridge filter, as well as a a 0.75GPM Dole valve that should in theory allow the well to recover faster than I pump water out (the recovery rate is 0.83GPM).

I have the Dole valve located after the filters because I was worried about the amount of sticky sediment plugging the valve, although I realize the flexible nature of the rubber valve orifice helps prevent that.

I have set up a few valves so I can close off the flow from well pump and backwash the media filter from clean water stored in the tank.

The only issue I'm running into so far is the amount of pressure that the deep well pump is building up thanks to the restriction from the dole valve. Even with the filters clean, I watched a 100 PSI pressure gauge make a full 360 and keep climbing before I shut the pump off probably in the 125PSI range. The pressure relief valve did open up, so I'll have to see if I can adjust it high enough.

I feel like the 0.75GPM flow should be enough to keep the pump cool, especially since it won't be working as hard because of the restriction, I just worry about how high the pressure is going to get, especially running through the backwash filter and the cartridge filter. As I said above I worry about locating the Dole valve before the filters because of just how much sediment gets pulled up and leading to it getting plugged.

Just looking for any thoughts or ideas of this being problematic? I guess the other option is getting a rather large pressure tank that the well pump can fill up over the course of 30 seconds to a minute, and then spend, say, 10-15 minutes emptying into the cistern. But I'd like to eliminate the pressure switch and bladder tank altogether if possible and just let the well pump be controlled by a timer and/or float switches.

My system looks something like this (excuse my MS Paint skills)

The well has a very low recovery rate and as the water level moves up and down in it stirs up a lot of sediment. To help reduce that sediment I have set up a backwash filter and a cartridge filter, as well as a a 0.75GPM Dole valve that should in theory allow the well to recover faster than I pump water out (the recovery rate is 0.83GPM).

I have the Dole valve located after the filters because I was worried about the amount of sticky sediment plugging the valve, although I realize the flexible nature of the rubber valve orifice helps prevent that.

I have set up a few valves so I can close off the flow from well pump and backwash the media filter from clean water stored in the tank.

The only issue I'm running into so far is the amount of pressure that the deep well pump is building up thanks to the restriction from the dole valve. Even with the filters clean, I watched a 100 PSI pressure gauge make a full 360 and keep climbing before I shut the pump off probably in the 125PSI range. The pressure relief valve did open up, so I'll have to see if I can adjust it high enough.

I feel like the 0.75GPM flow should be enough to keep the pump cool, especially since it won't be working as hard because of the restriction, I just worry about how high the pressure is going to get, especially running through the backwash filter and the cartridge filter. As I said above I worry about locating the Dole valve before the filters because of just how much sediment gets pulled up and leading to it getting plugged.

Just looking for any thoughts or ideas of this being problematic? I guess the other option is getting a rather large pressure tank that the well pump can fill up over the course of 30 seconds to a minute, and then spend, say, 10-15 minutes emptying into the cistern. But I'd like to eliminate the pressure switch and bladder tank altogether if possible and just let the well pump be controlled by a timer and/or float switches.