newBasementMN

New Member

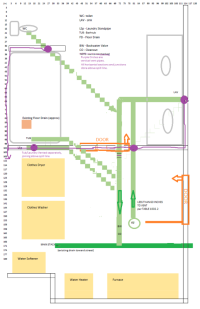

We're almost ready to start breaking up the floor, but have some questions. This forum has been invaluable as a reader, and I was able to answer so many questions just by reading what everyone else had to say! I've done plenty of supply lines as an amateur, but never DWV. We're in urban Minnesota, and everything will be permitted/inspected. Basement on slab, built 1950s

(1) we want to remove the current floor drain. Do we have to remove all the pieces, or can we just cap and bury any parts that aren't in our way?

(1b) would it ever be allowed to leave the connection between the old floor drain and the main drain line? This won't be protected by the backwater valve, but would be capped.

(2) we need to add a backwater valve. Do we want a cleanout upstream, downstream, or both? What's code vs. what makes best sense?

(2b) where do we need cleanouts on this whole thing? Under the vanity, right? And then just about everything accumulates 135 degrees before joining the main line, so where else? Does the floor drain count as a cleanout?

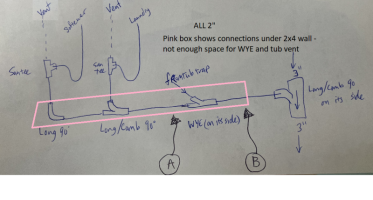

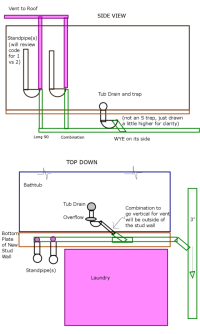

(3) Does the floor drain need its own vent? (edit: inspector says yes). Since drain is in the middle of the room, can the vent follow our trench back "upstream?" Like we run two pipes side by side, one waste, one vent, in the trench and it exits closer to the laundry standpipe? I don't really understand wet venting, but does that apply here at all?

(4) Can the laundry standpipe also receive water softener discharge? Is the answer here just to do two standpipes, side by side, vented separately? (edit: inspector says air gap then into floor drain for this, but that sounds like it'll just splash everything. Would it be better to share one standpipe or build two?)

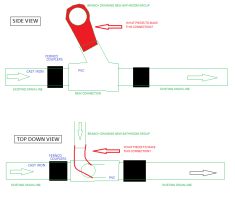

(5) When everything drains into the main line, does it need to be at the same elevation? Or can it come from above and "dump" into a WYE that's rotated at least 45 degrees toward vertical? This questions depends on how deep the drain line is, but if we have the opportunity to save some digging by adding a vertical drop, I'm all for it! (yes everything will be sloped properly, this is more "can we go horizontal to vertical to horizontal like that?")

(6) With this drawing, the toilet needs its own vent, right? Should we switch to a right-hand bathtub so that the toilet can share its vent?

(7) What other changes would you suggest for this plan?

Sorry if that's a lot all at once. I really appreciate all your help.

(1) we want to remove the current floor drain. Do we have to remove all the pieces, or can we just cap and bury any parts that aren't in our way?

(1b) would it ever be allowed to leave the connection between the old floor drain and the main drain line? This won't be protected by the backwater valve, but would be capped.

(2) we need to add a backwater valve. Do we want a cleanout upstream, downstream, or both? What's code vs. what makes best sense?

(2b) where do we need cleanouts on this whole thing? Under the vanity, right? And then just about everything accumulates 135 degrees before joining the main line, so where else? Does the floor drain count as a cleanout?

(3) Does the floor drain need its own vent? (edit: inspector says yes). Since drain is in the middle of the room, can the vent follow our trench back "upstream?" Like we run two pipes side by side, one waste, one vent, in the trench and it exits closer to the laundry standpipe? I don't really understand wet venting, but does that apply here at all?

(4) Can the laundry standpipe also receive water softener discharge? Is the answer here just to do two standpipes, side by side, vented separately? (edit: inspector says air gap then into floor drain for this, but that sounds like it'll just splash everything. Would it be better to share one standpipe or build two?)

(5) When everything drains into the main line, does it need to be at the same elevation? Or can it come from above and "dump" into a WYE that's rotated at least 45 degrees toward vertical? This questions depends on how deep the drain line is, but if we have the opportunity to save some digging by adding a vertical drop, I'm all for it! (yes everything will be sloped properly, this is more "can we go horizontal to vertical to horizontal like that?")

(6) With this drawing, the toilet needs its own vent, right? Should we switch to a right-hand bathtub so that the toilet can share its vent?

(7) What other changes would you suggest for this plan?

Sorry if that's a lot all at once. I really appreciate all your help.

Attachments

Last edited: