That's a good starting point- way better than 50 psi.

So, how much pipe is there (of what size) feeding the water heater, and how much is there between the water heater and hot side of the tempering valve?

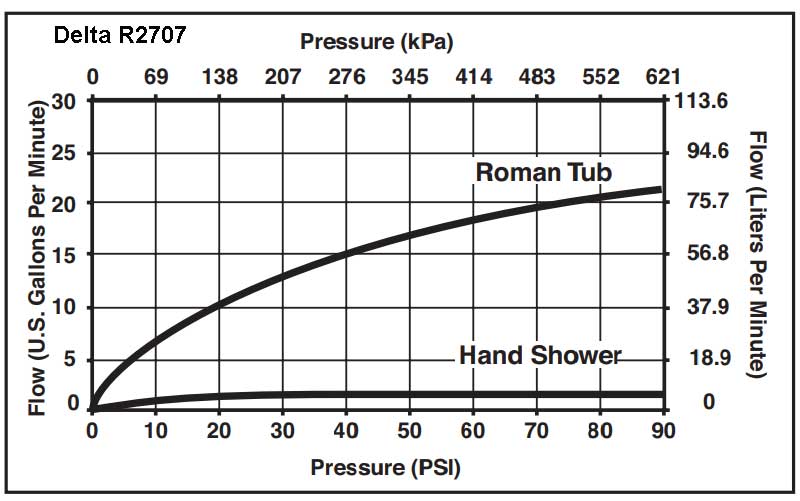

Take a look at the graph on

the spec. If it had the full 91 psi at the faucet you'd get the 19 gpm, at 40 psi it's still good for 15 gpm, at 20 psi it's good for 10 gpm. If it's only delivering 5 gpm something in the path is imposing a big pressure drop. Long skinny pipes are probably the major culprit, but not the only culprit.

An inexpensive

half-inch Watts tempering valve delivers a pressure drop of 8 psi even at your measured 5 gpm flow, 10 psi at 5.5 gpm. The pressure drop looks like it's growing exponentially from there. Care to guess what the drop is at 10 gpm? (Probably over 50 psi would be my guess.)

The 3/4 inch version version inserts only 10psi @ 10 gpm, but there are some (not so cheap) 3/4" thermostatic mixing valves that take much less of a bite than that.

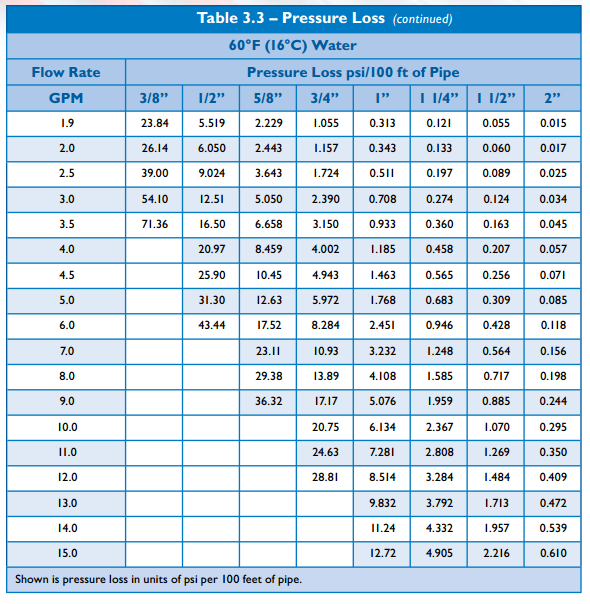

The 600' of 1" PEX is also taking a toll:

At your measured 5 gpm it's inserting 6 x 1.768= 11.6 psi drop.

If your target it 10 gpm it would be inserting 6 x 6.134= 37 psi drop. That combined with the half-inch tempering valve you wouldn't have enough static pressure to get you to that flow rate, even without factoring in the half-inch PEX in between.

So take some measurements to estimate the amount of half-inch PEX in the path, and start looking at specs for fatter thermostatic mixing valves with lower drop. You probably won't make it to 15 gpm on the pipe you have, but there's at least a remote shot at 10, which is twice the flow you're measuring.

But that won't fix the mixing volume issue.

Do try to get a better handle on the actual fill volume. It's tough enough to fill even a standard 70-80 gallon soaker tub acceptably hot with a 50 gallon water heater, let alone a tub in the 100+ gallons range.