Tom McDonald

New Member

Hello,

I’ve been lurking on these forums for a while as I’ve dealt with some water issues in a house we bought in the fall of 2018. A lot of good information here helped put me on a path to a solution, but a recent water test makes me think I’m backsliding.

The property was new construction, with a relatively deep well (~350 ft). We knew that there was an abundance of iron & manganese (2.2 ppm and 0.08 ppm, respectively) prior to purchasing, but failed to realize the large impact of that iron on things like fixtures, laundry, and taste/odor as well as the difficulty in dealing with it. I sought a number of professional opinions, but most were only interested in installing a water softener setup. We also have soft water (hardness of 30). My research here and elsewhere suggested that a purpose-built system would be more effective in the long term and would be easier to maintain, so I set about getting that installed.

The setup (all with 1” Cu piping):

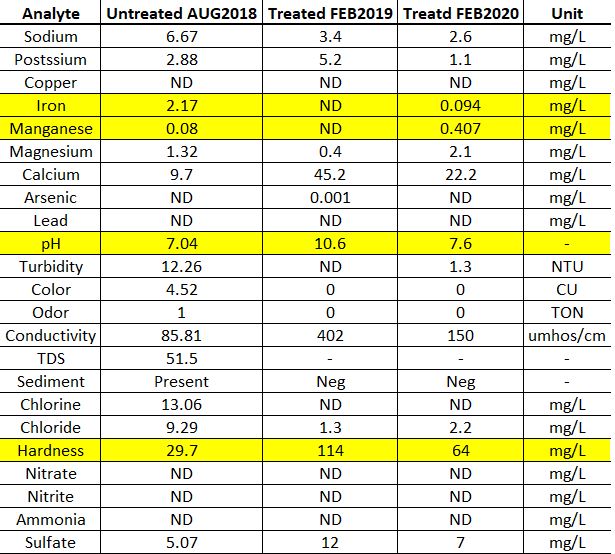

After the system was running for a few weeks (February of 2019), I took some water samples in for a full panel with a state-certified water testing facility. Generally, the treatment was effective, as the iron and manganese levels were below the limit of detection. However, the pH spiked from 7.04 to 10.6 and the hardness from 30 to 114. Again, based on the experiences around here, I figured this was normal, and did more frequent flushes and monitored the pH until it got south of 8.5.

Towards the end of 2019, the aroma / taste of iron started cropping back up periodically, so earlier this month I took a sample in for a full panel test. While the iron has creeped back up (new test at 0.094 ppm vs ND after system install vs 2.17 untreated) the manganese has exploded (new test at 0.407 ppm vs ND after system install vs 0.08 untreated). For what its worth, the pH has now come all the way down to 7.6 and the hardness to 64. Now, I haven’t tested the untreated water again to look for changes in the aquafer (will do so), but I am more concerned about the inability of the filter to remove manganese. Even more worrisome is if the untreated water is not higher in manganese than before, meaning the filter could be leaching MnO into the treated water. I think that this is unlikely, but am concerned.

So, as I think about how to tackle this, a few options come to mind:

Any advice that you all might have would be highly appreciated. Sorry for the rambling post.

Thanks!

I’ve been lurking on these forums for a while as I’ve dealt with some water issues in a house we bought in the fall of 2018. A lot of good information here helped put me on a path to a solution, but a recent water test makes me think I’m backsliding.

The property was new construction, with a relatively deep well (~350 ft). We knew that there was an abundance of iron & manganese (2.2 ppm and 0.08 ppm, respectively) prior to purchasing, but failed to realize the large impact of that iron on things like fixtures, laundry, and taste/odor as well as the difficulty in dealing with it. I sought a number of professional opinions, but most were only interested in installing a water softener setup. We also have soft water (hardness of 30). My research here and elsewhere suggested that a purpose-built system would be more effective in the long term and would be easier to maintain, so I set about getting that installed.

The setup (all with 1” Cu piping):

- Well Pump to a Pressure tank

- Pressure tank to a three valve bypass loop

- Bypass loop (treatment leg) to Fleck 5810 XTR2 + 54” x 10” media tank, filled with 1.5 cu ft of Katalox light

- Media tank to Big Blue 20” filter housing equipped with a polypropylene filter (3M Aqua-Pure AP810-2, 5 um) that is changed quarterly

- Sediment filter back to the bypass loop

After the system was running for a few weeks (February of 2019), I took some water samples in for a full panel with a state-certified water testing facility. Generally, the treatment was effective, as the iron and manganese levels were below the limit of detection. However, the pH spiked from 7.04 to 10.6 and the hardness from 30 to 114. Again, based on the experiences around here, I figured this was normal, and did more frequent flushes and monitored the pH until it got south of 8.5.

Towards the end of 2019, the aroma / taste of iron started cropping back up periodically, so earlier this month I took a sample in for a full panel test. While the iron has creeped back up (new test at 0.094 ppm vs ND after system install vs 2.17 untreated) the manganese has exploded (new test at 0.407 ppm vs ND after system install vs 0.08 untreated). For what its worth, the pH has now come all the way down to 7.6 and the hardness to 64. Now, I haven’t tested the untreated water again to look for changes in the aquafer (will do so), but I am more concerned about the inability of the filter to remove manganese. Even more worrisome is if the untreated water is not higher in manganese than before, meaning the filter could be leaching MnO into the treated water. I think that this is unlikely, but am concerned.

So, as I think about how to tackle this, a few options come to mind:

- Add a chemical oxidant directly to the filter during regeneration via stenner pump – can’t seem to find a lot of information on this approach for whatever reason

- Add chemical oxidant via stenner pump either via a pre-tank mixer, or into a baffled contact tank with bottom drain – seems straightforward enough

- Air injection system – not sure how this actually works; have seen suggestions that an air gap in the media tank accomplishes this, but it seems like any airgap in a water pressurized tank would be vanishingly small and have minimal contact with the water. Seems like they would foul in odd ways too.

Any advice that you all might have would be highly appreciated. Sorry for the rambling post.

Thanks!