TunaBreath

New Member

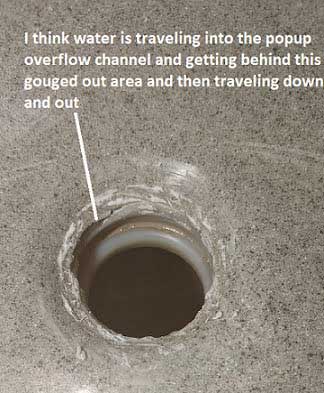

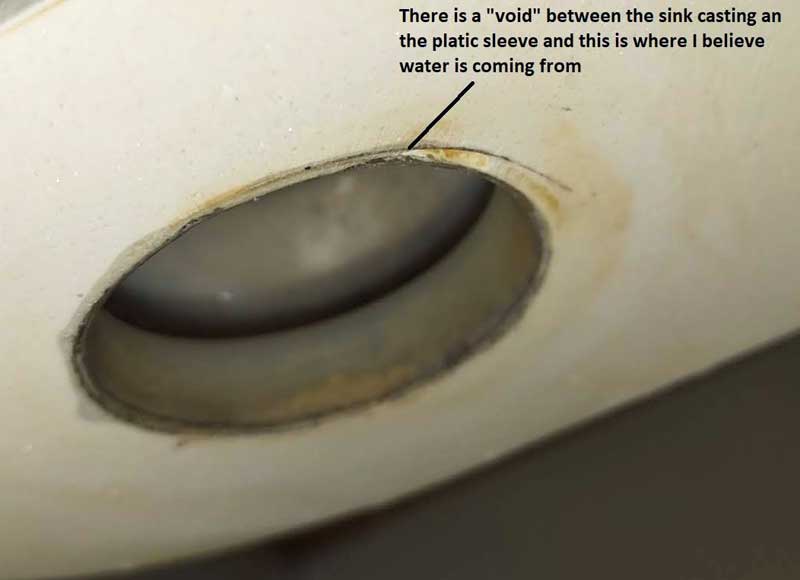

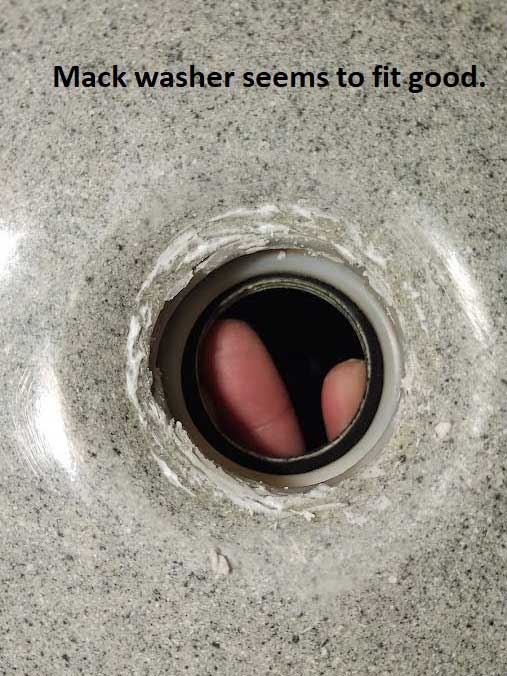

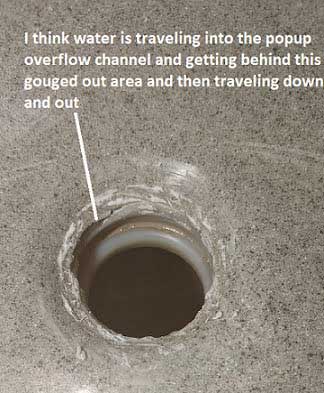

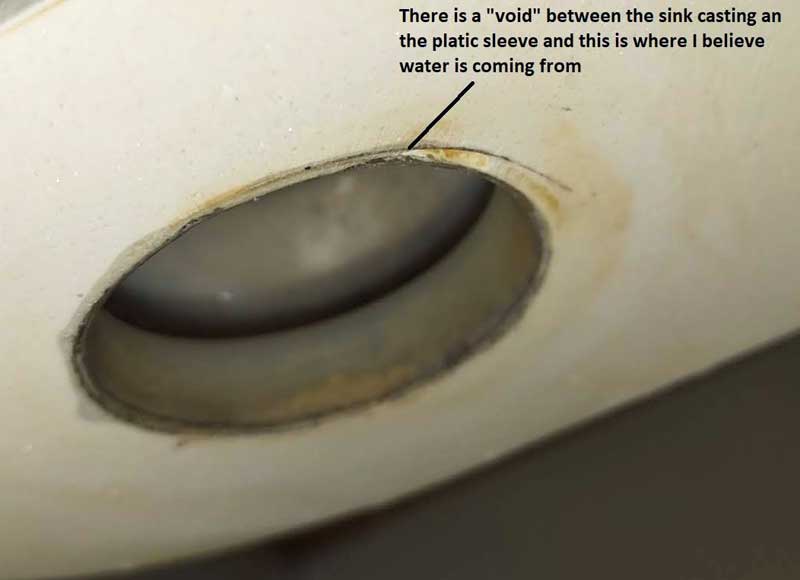

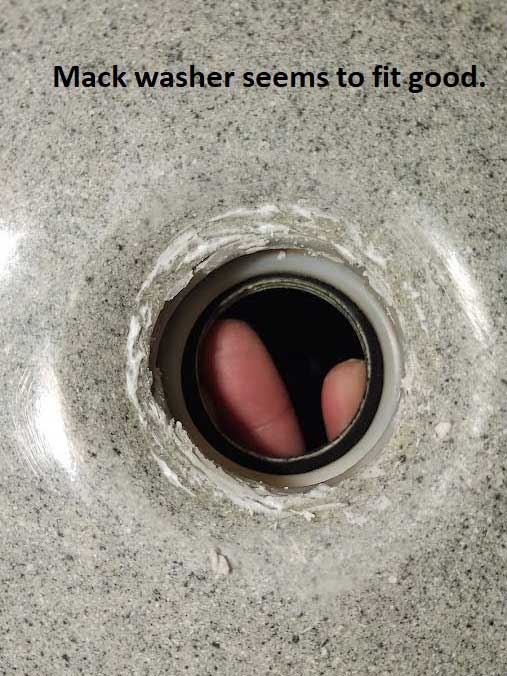

Hey guys, fighting a leak at a lav sink outlet at the mack washer from installing a new Moen faucet and pop up drain w/ overflow (sink has overflow). I attached some photos but I can not stop a leak at the mack washer. This a custom lav top from when the house was built in 2005 and it had a plastic sleeve through the drain outlet, some of which I had to cut away when installing the new popup as the popup would not sit flush or tight to the sink outlet without cutting some away (I did the same thing on another sink in the house years ago).

The only thing I can think of is that water is going into the sink overflow inlet on the popup assembly and making its way BEHIND the plastic sleeve and then traveling down and out of there. See the attached photos.

I have tried plumbers putty on the mack washer, tried heavy tightening, not so heavy tightening thinking it was being distorted but no luck. What are my options? Right now I am thinking of attempting to cut and peel out all of that plastic sleeve.

Trying to attach photos but even 230KB is too big?

Link for photos:

The only thing I can think of is that water is going into the sink overflow inlet on the popup assembly and making its way BEHIND the plastic sleeve and then traveling down and out of there. See the attached photos.

I have tried plumbers putty on the mack washer, tried heavy tightening, not so heavy tightening thinking it was being distorted but no luck. What are my options? Right now I am thinking of attempting to cut and peel out all of that plastic sleeve.

Trying to attach photos but even 230KB is too big?

Link for photos:

Last edited: