Rossn

Member

The questions:

1) Given an instantaneous 50A load (makeup air heater), what is a reasonable tripping threshold to target for an energy management system overseeing a 200A OCPD?

If it was set to 150A, then the EMS would not benefit me because it is not providing extra capacity. At 160%, it is really only freeing up 10A. At 200A, it is most useful, but it means that the OCPD could see 250A for a short period before it disconnects the device, and this could be a regular occurrence.

2) Is one to infer from the time-current curves of an OCPD and NEC that residential electrical systems seeing a load 25% beyond OCPD for a few seconds (until EMS kicks in), on a regular basis is acceptable and within the capabilities of a NEC compliant electrical system (mainly thinking about feeders)? It would be great to understand a professionals' point of view on this.

The background:

In my remodel, I have a situation by which my load calculations will (eventually) exceed my capacity (namely one 50A heating load for the makeup air system), thus there will be a need for an energy management system. There is a possibility that I may be able to meet NEC needs by monitoring usage, but need to have a clear solution in the event that does not pan out.

In reviewing available energy management systems (many of which are oriented towards EVSEs), many use CTs to monitor load on the feeders for a given panel or service, and then cut power to a device if the current draw for the panel or service exceeds that threshold. Different EMS's use different thresholds. Some 80%, some configurable at 80% or 100%, some can be configured or any threshold.

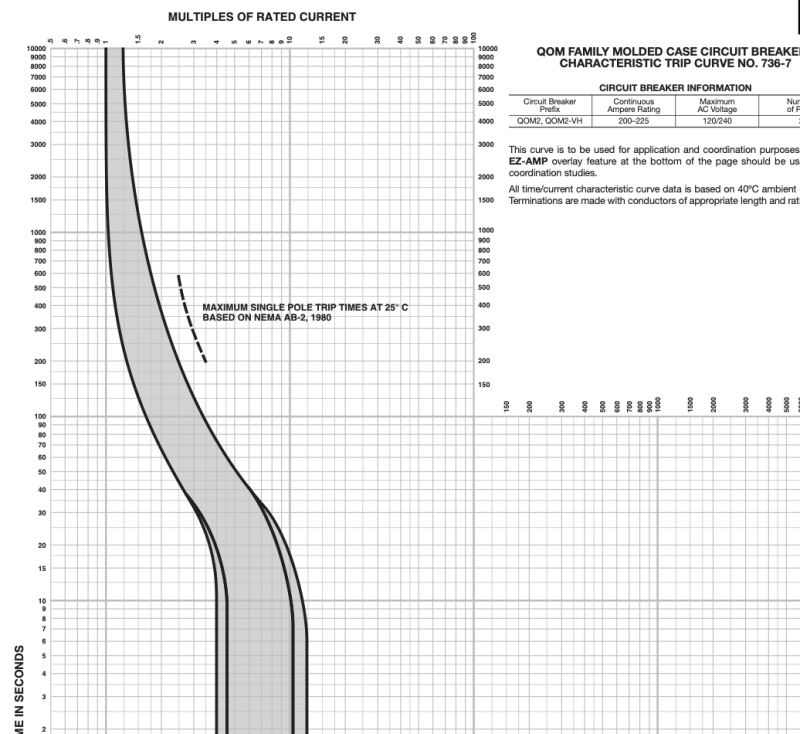

I believe my main breaker trip curves are below (awaiting confirmation from Schneider). From this it appears that, for example, on this 200A OCPD:

250A (125%) load trips between about 200s and 10,000s (or greater). And a 300A (150%) load trips between 125s and 1250s. Having not looked at time-current main breaker curves previously, I was surprised. I thought they would be more sensitive. Perhaps this implies that it is reasonable for a feeder of a 200A breaker to also see the higher (say 250A) current for shorter periods of time (seconds).

1) Given an instantaneous 50A load (makeup air heater), what is a reasonable tripping threshold to target for an energy management system overseeing a 200A OCPD?

If it was set to 150A, then the EMS would not benefit me because it is not providing extra capacity. At 160%, it is really only freeing up 10A. At 200A, it is most useful, but it means that the OCPD could see 250A for a short period before it disconnects the device, and this could be a regular occurrence.

2) Is one to infer from the time-current curves of an OCPD and NEC that residential electrical systems seeing a load 25% beyond OCPD for a few seconds (until EMS kicks in), on a regular basis is acceptable and within the capabilities of a NEC compliant electrical system (mainly thinking about feeders)? It would be great to understand a professionals' point of view on this.

The background:

In my remodel, I have a situation by which my load calculations will (eventually) exceed my capacity (namely one 50A heating load for the makeup air system), thus there will be a need for an energy management system. There is a possibility that I may be able to meet NEC needs by monitoring usage, but need to have a clear solution in the event that does not pan out.

In reviewing available energy management systems (many of which are oriented towards EVSEs), many use CTs to monitor load on the feeders for a given panel or service, and then cut power to a device if the current draw for the panel or service exceeds that threshold. Different EMS's use different thresholds. Some 80%, some configurable at 80% or 100%, some can be configured or any threshold.

I believe my main breaker trip curves are below (awaiting confirmation from Schneider). From this it appears that, for example, on this 200A OCPD:

250A (125%) load trips between about 200s and 10,000s (or greater). And a 300A (150%) load trips between 125s and 1250s. Having not looked at time-current main breaker curves previously, I was surprised. I thought they would be more sensitive. Perhaps this implies that it is reasonable for a feeder of a 200A breaker to also see the higher (say 250A) current for shorter periods of time (seconds).