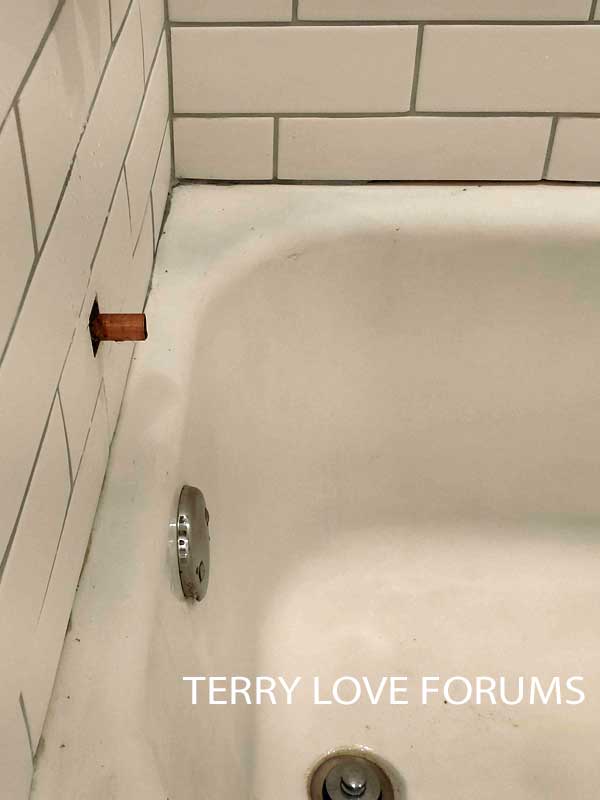

i have a delta tub faucet i'm installing.

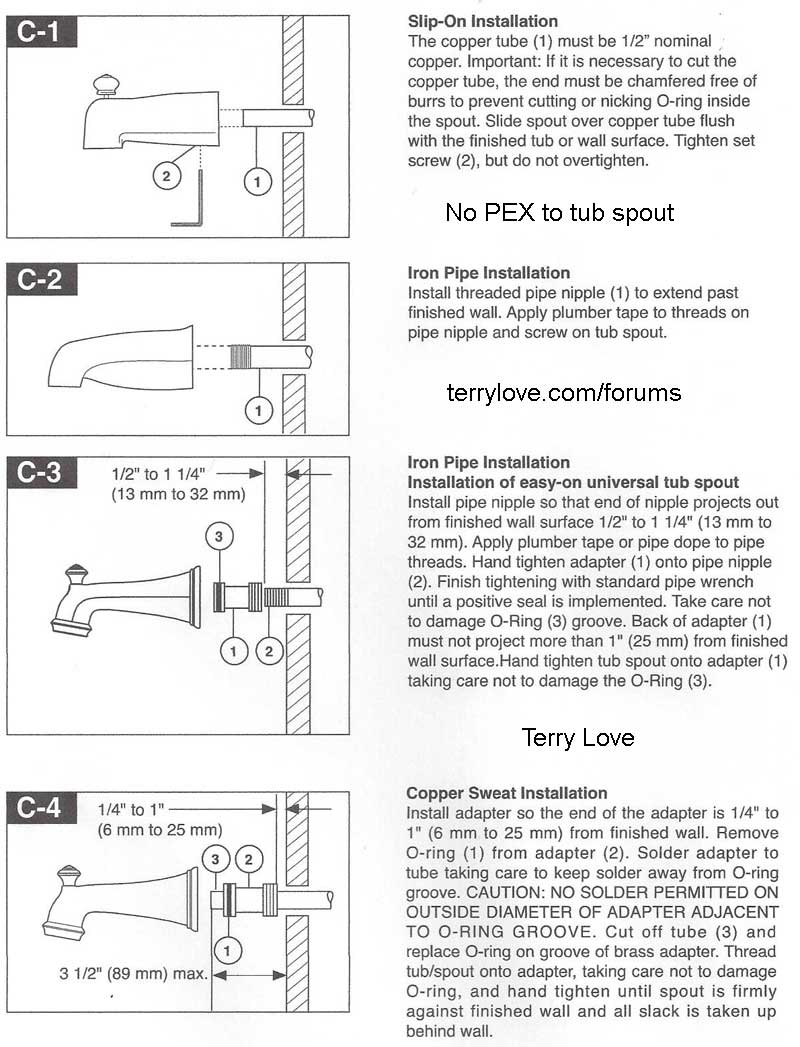

i see other posts about this. i'm wondering if this product that slips inside the 1/2" copper pipe would work? it would restrict flow a bit but would it matter all that much? this sioux chief product

https://hdsupplysolutions.com/p/1-2...sion-nipple-adapter-kit-for-tub-spout-p845045

current i have a 'slip' on adapter. should i purchase a threaded adapter + solder 1/2" pipe + solder on a threaded piece at the end?

delta slip-on tub spout adapter (one i have now):

https://www.deltafaucet.com/parts/product/RP33794.html

threaded tub spout adapter (should i buy this one?):

https://www.deltafaucet.com/parts/product/RP12307.html

references

https://terrylove.com/forums/index.php?threads/copper-pipe-too-short-to-install-tub-spout.40016/

i see other posts about this. i'm wondering if this product that slips inside the 1/2" copper pipe would work? it would restrict flow a bit but would it matter all that much? this sioux chief product

https://hdsupplysolutions.com/p/1-2...sion-nipple-adapter-kit-for-tub-spout-p845045

current i have a 'slip' on adapter. should i purchase a threaded adapter + solder 1/2" pipe + solder on a threaded piece at the end?

delta slip-on tub spout adapter (one i have now):

https://www.deltafaucet.com/parts/product/RP33794.html

threaded tub spout adapter (should i buy this one?):

https://www.deltafaucet.com/parts/product/RP12307.html

references

https://terrylove.com/forums/index.php?threads/copper-pipe-too-short-to-install-tub-spout.40016/