Giantsean

Member

Hi All,

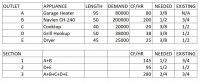

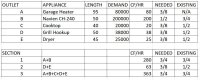

Our home has a 2PSI gas system piped with Gastite Flashshield (the anti-lightning stuff). Right now it runs a Navien CH-240, cooktop, dryer, as well as an outdoor quick connect hookup for an NG grill. The original trunk is 3/4 from meter to tees where 1/2 lines for the cooktop/dryer/grill split off (in a couple of places due to the way they were added). Right now everything works as it should.

I really want to add an 80K BTU NG garage heater and trying to budget for it. If I want to stay w/ Gastite the cost difference of the 1/2 vs. 3/4 is considerable, so much so that it may be a dealbreaker (esp. at the local going rate).

I have tried using some "longest length" gas capacity formulas along w/ Gastite's own standard 2PSI max capacity tables, using very conservative lengths (longer than needed, using actual line lengths w/ some fluff) and it APPEARS that I can tee off close to the furnace and run 1/2" to the garage, but my original gut feel was I'd need 3/4. The only way I got the tables to not work was with Gastite's "custom" table creator where you enter PSI and min/max length, but it said I needed 1" to the Navien by itself so I'm guessing I did it wrong. Still the 2PSI service looks like it buys me a lot of flexibility.

Just to make clear... I have no plans to install gas lines myself - I'm comfortable w/ appliance hookups but that's about as far as I'll go. Also nobody in the area will sell Gastite to homeowners unless they are certified. Again, just trying to plan out as best I can. If I can save a buck (or hundreds lol) I'm looking to do so. Attached a crappy map and some of my calculations.

Sincere thanks for any advice, and stay safe!

Our home has a 2PSI gas system piped with Gastite Flashshield (the anti-lightning stuff). Right now it runs a Navien CH-240, cooktop, dryer, as well as an outdoor quick connect hookup for an NG grill. The original trunk is 3/4 from meter to tees where 1/2 lines for the cooktop/dryer/grill split off (in a couple of places due to the way they were added). Right now everything works as it should.

I really want to add an 80K BTU NG garage heater and trying to budget for it. If I want to stay w/ Gastite the cost difference of the 1/2 vs. 3/4 is considerable, so much so that it may be a dealbreaker (esp. at the local going rate).

I have tried using some "longest length" gas capacity formulas along w/ Gastite's own standard 2PSI max capacity tables, using very conservative lengths (longer than needed, using actual line lengths w/ some fluff) and it APPEARS that I can tee off close to the furnace and run 1/2" to the garage, but my original gut feel was I'd need 3/4. The only way I got the tables to not work was with Gastite's "custom" table creator where you enter PSI and min/max length, but it said I needed 1" to the Navien by itself so I'm guessing I did it wrong. Still the 2PSI service looks like it buys me a lot of flexibility.

Just to make clear... I have no plans to install gas lines myself - I'm comfortable w/ appliance hookups but that's about as far as I'll go. Also nobody in the area will sell Gastite to homeowners unless they are certified. Again, just trying to plan out as best I can. If I can save a buck (or hundreds lol) I'm looking to do so. Attached a crappy map and some of my calculations.

Sincere thanks for any advice, and stay safe!

Attachments

Last edited: