Dana, thanks for the links above. I'm learning a ton about boilers.

According to this site,

https://www.hunker.com/13408622/what-size-boiler-is-needed-per-square-foot-of-a-house

they recommend 33.475 BTUs of power output per square foot.

That recommendation is

utter crap, and would oversize the heat at

my house by more than 2x! If my house were in a location/climate as temperate as yours it would be oversized by more than 3x!

Further down in that same article they eventually get around to:

Calculating Your Exact Needs

HVAC professionals use a method called Manual J Load to calculate the exact boiler needs for a space. This scientific method requires assigning values to factors such as home construction materials, insulation levels, size of rooms, number of windows and creating an overall value for your home based on this.

A Manual-J done correctly using the most aggressive (rather than conservative) assumptions possible is the gold standard, and will usually oversize by no more than 1.15x.

Correlating fuel-use data with outdoor temperature data (heating degree-days), is an actual

measurement, and will usually come in lower than a Manual-J, but is more accurate if using wintertime only data, on periods that consistently have at least

some heat load(= no days over 65F.)

A 1200 square foot house with at least some wall & attic insulation and clear-glass (not low-E) double-panes (or clear storm windows over single panes), and no foundation insulation will have a likely heat load is less than 20,000 BTU/hr @ +17F (the

99% outside design temp for Andrews AFB). Run a fuel use load calculation to find out. ASHRAE recommends an oversize factor of 1.4x, so with a 20K heat load the "ideal" non-modulating boiler would have an output of about 28,000 BTU/hr. There are a few cast iron boilers that would b small enough, but with big cast iron radiators there would need to be protective measures taken to avoid destroying the boiler with condensation on the heat exchanger plates. A condensing boiler would be a better choice, to take advantage of those cool temps for higher efficiency.

With modulating condensing boiler the minimum firing rate is more critical than the maximum firing rate, as long as the max still covers your design load with some margin. Your load is probably low enough that it might be easier to right-size ductless or ducted heat pumps. But if replacing the boiler, a modulating condensing boiler with a very low (under 8000 BTU/hr) minimum firing rate that adjusts the output temperature in response to the outdoor temperature (called "outdoor reset") would use less fuel and provide higher comfort levels than a smaller, right-sized cast iron boiler.

That's around 40k btu which is half what my boiler puts out.

Does that mean my radiators get hotter fast or am I spending close to twice as much money in natural gas to heat my house?

The boiler is 17 years old.

Thanks for your help,

jb

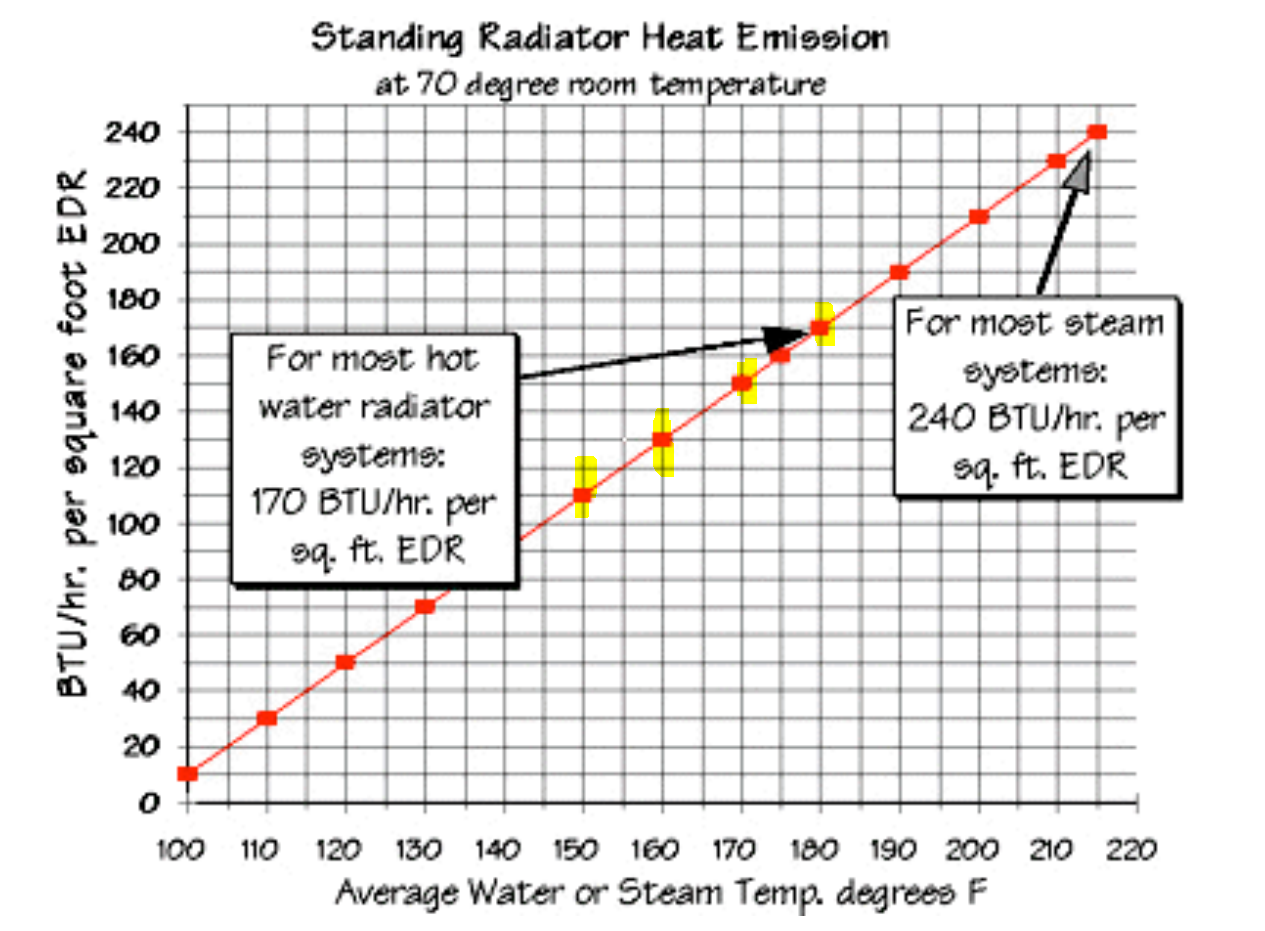

It does mean that the radiators get hotter faster, but getting hotter faster also results in temperature overshoot- it's only useful for deep overnight setbacks.

It's using more fuel than a right-sized boiler, but not twice as much. AFUE testing is done at a presumptive 1.7x oversize factor, and is usually within 1% of the boiler's steady state efficiency or raw combustion efficiency. But when 2-3x oversized the boiler operates at an extremely low duty cycle, and suffers increasingly significant standby losses, since the boiler fires up, runs for several minutes is still hot at the end of a burn retaining a lot of heat, but may not cycle on again for hours. The idling losses at 3x oversizing are big enough to reduce the "as-used" efficiency to 10-15% or so below the steady-state or AFUE efficiency. At 4-5x oversizing (roughly where you are) it will probably be more than 15%. So instead of 82-83% efficiency your boiler is probably delivering no more than 70% efficiency, with most of the wasted heat going into the boiler room. If you're keeping the boiler (I might, if it's still testing at a raw combustion efficiency of better than 78%), installing a retrofit heat-purging boiler control such as the

Intellicon HW+ or

HydroStat 3250 Plus will reduce those idling losses to only a few percent. See

System #3 in Table 3 of this document, the only boiler tested that used a heat purging controller, and compare it's performance to the others at 3x oversizing.

A ~7" x 7"terra cotta liner 23' extending 23' above where the vents enter is a bit oversized for 130K of 80-83% efficiency burner, but isn't going to be a disaster. If it's on an exterior wall there will be some backdrafting potential on cold days, but if it runs up the middle of the house in a chase surrounded by conditioned space it should be fine.