qlopp

New Member

Hi,

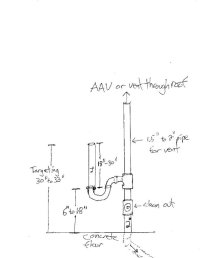

I have a restricted trap below my laundry standpipe that can no longer handle the spin cycle output of my washing machine. It is the original installation from 1962; a 2" cast iron pipe goes below the concrete floor to a buried trap. Several times over the last 15 years I was able to snake it out with a 3/8" power drum snake and small "cutter" (I took a beehive attachment and cut off all but a little spur of the wire so that it would be slinky enough to make it through the trap). I can't snake it anymore due to corrosion bloom inside the trap.

This standpipe is just a stub and is not vented externally. It is located in a corner of the basement, 9" from the gable end wall of the house and 36" from the front wall of the house. It is one foot horizontally from a hopper window on the gable wall.

I've done research on what the correct repair would involve, which is to bring it up to code by cutting out the old trap and retrofitting an above floor trap. Then the drain must be vented to the exterior. It is here where I am unsure about all of the plumbing code stipulations. Paraphrasing from several sources, the vent terminal must be 10+ feet above outdoor ground level, then it must be 10+ feet horizontally from an openable window/door or intake/exhaust port unless it is 3+ feet above such opening(s). Unfortunately there is a basement hopper window very close to the drain location and one window each on the first and second floors above that window. By the time I navigated around these restrictions I would be at the attic level. Therefore roof exit seems like the only choice.

I am in an unincorporated county area which has adapted IPC. We have the least layers of government oversight in the populated areas of the greater metro area. Is there any chance of being granted a variance for retrofitting such a code compliance upgrade in a simpler manner than going all the way through the roof? Maybe a wall exit compromise that inspectors would allow in this situation, given the difficulty of achieving full compliance? It's not a conventional soil stack (so no human or food waste) and the trap breaks vapors from the lateral it connects to, so I don't consider that unreasonable.

If I hire a company to do this, how involved is running a pipe inside the exterior wall, up two stories and through the roof of a stick frame house, including flashing/roofing restoration and patching/restoring the appearance of any access holes in the walls? It seems like an expensive proposition, but maybe it's not as bad as I'm thinking.

Thanks for reading!

I have a restricted trap below my laundry standpipe that can no longer handle the spin cycle output of my washing machine. It is the original installation from 1962; a 2" cast iron pipe goes below the concrete floor to a buried trap. Several times over the last 15 years I was able to snake it out with a 3/8" power drum snake and small "cutter" (I took a beehive attachment and cut off all but a little spur of the wire so that it would be slinky enough to make it through the trap). I can't snake it anymore due to corrosion bloom inside the trap.

This standpipe is just a stub and is not vented externally. It is located in a corner of the basement, 9" from the gable end wall of the house and 36" from the front wall of the house. It is one foot horizontally from a hopper window on the gable wall.

I've done research on what the correct repair would involve, which is to bring it up to code by cutting out the old trap and retrofitting an above floor trap. Then the drain must be vented to the exterior. It is here where I am unsure about all of the plumbing code stipulations. Paraphrasing from several sources, the vent terminal must be 10+ feet above outdoor ground level, then it must be 10+ feet horizontally from an openable window/door or intake/exhaust port unless it is 3+ feet above such opening(s). Unfortunately there is a basement hopper window very close to the drain location and one window each on the first and second floors above that window. By the time I navigated around these restrictions I would be at the attic level. Therefore roof exit seems like the only choice.

I am in an unincorporated county area which has adapted IPC. We have the least layers of government oversight in the populated areas of the greater metro area. Is there any chance of being granted a variance for retrofitting such a code compliance upgrade in a simpler manner than going all the way through the roof? Maybe a wall exit compromise that inspectors would allow in this situation, given the difficulty of achieving full compliance? It's not a conventional soil stack (so no human or food waste) and the trap breaks vapors from the lateral it connects to, so I don't consider that unreasonable.

If I hire a company to do this, how involved is running a pipe inside the exterior wall, up two stories and through the roof of a stick frame house, including flashing/roofing restoration and patching/restoring the appearance of any access holes in the walls? It seems like an expensive proposition, but maybe it's not as bad as I'm thinking.

Thanks for reading!