Ted S

New Member

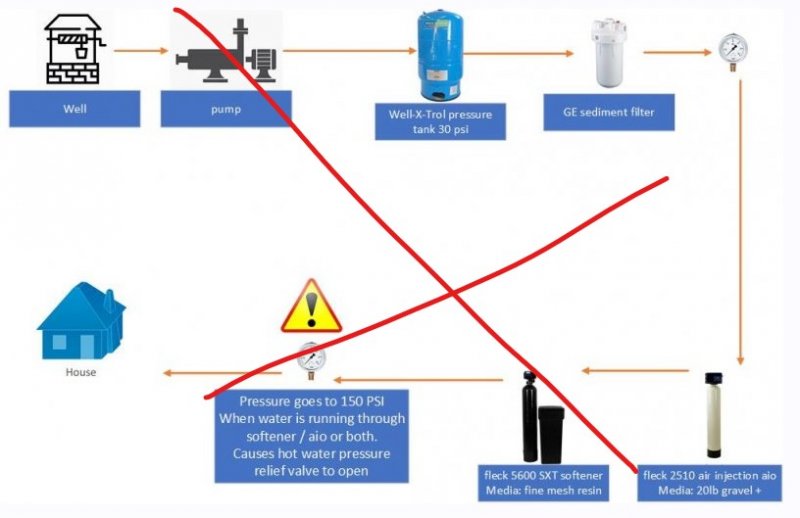

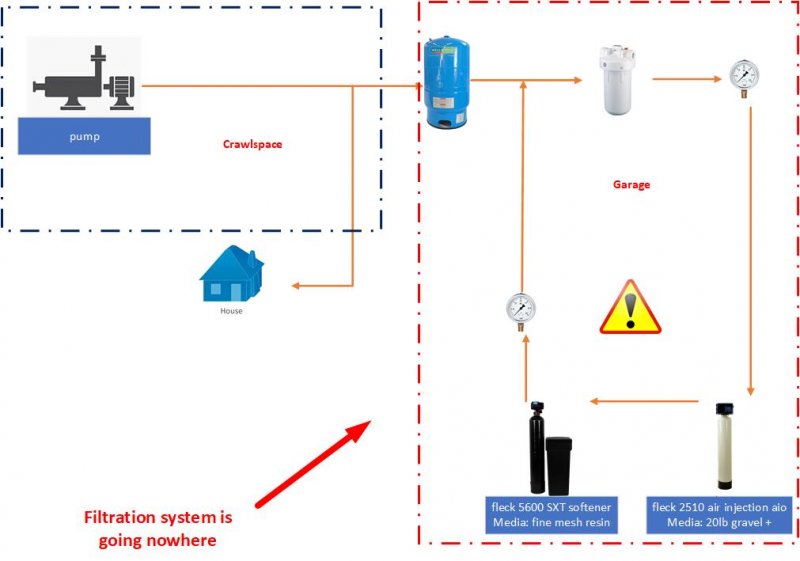

Update: After posting this. I found major issue in this setup. Please see my updated figure below.

The issue is that the filtration loop was going nowhere. The diagram explains it best.

Hello,

Please bear with me as I explain the situation. It is very odd and I cannot find a resolution. I hope this is the right place for this question.

Summary: High pressure in the system only when I run the filtration system regeneration or in service mode!

Equipment:

The issue is that the filtration loop was going nowhere. The diagram explains it best.

Hello,

Please bear with me as I explain the situation. It is very odd and I cannot find a resolution. I hope this is the right place for this question.

Summary: High pressure in the system only when I run the filtration system regeneration or in service mode!

Equipment:

- Fleck 2510 AIO (10 x 54)

- Fleck 5600 SXT (10 x 54)

- Can occur with either AIO and softener in service or both.

- Occurs with AIO in regeneration mode (air injection).

- Pressure rises steadily within about a minute from 45 psi to about 150

- Occurs with softener regeneration mode.

- Does not happen in backwash mode.

- Does not happen in rapid rinse mode.

- With high pressure, fine mesh ends up in all faucets and toilets

- Hot water tank relief valve opens up and releases pressure

- Can relieve the pressure if I open one of the faucets (high water pressure)

- Can also relieve the pressure by putting the tanks in bypass mode. (then I hear pressure adjustments in the pipes / water tank)

- Well pressure tank never goes above 45 psi

- Rebuilt the system.

- Checked that the baskets are not clogged or cracked.

- Replaced sediment filters.

- Triple checked the settings for each...

- Made sure no air is in the system / pipes.

Last edited: