I'm confused as to why you are using the word ramp. Isn't there going to be a step? So it's a 2x6 platform? A ramp to me connotes something with no step, just an incline.

1) The AAV can be via a tubular connection under the sink, it just needs to be at least 4" above the horizontal fixture drain. There are various kits like this one to facilitate that:

https://rectorseal.com/magic-trap-kit/ With separate lav drains, you' d need to do this for each lav. Thinking about it some more, the only real upside of separating the lav drains is to avoid the 3" pipe for the wet vent on the WC. Which is significant and probably worth it.

2) For the 1-1/2" lav fixture drain, with a trap adapter under the sink, you can remove the trap and use it for a cleanout. I'm a bit unclear on what if any cleanouts should exist on the 2" pipe. Obviously you can access the branch drain through the lav fixture drain, but a 2" cleanout would give better access. And your layout does have a lot of horizontal bends.

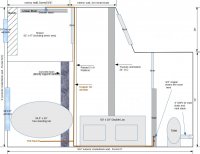

3) As to the picture, yes connectivity wise, but a few further tweaks/comments:

- The end where it says "to WC and 4" pipe", that needs to join in downstream of the WC and other lav. [If it joins upstream of the WC, now the WC wet vent is carrying over 4 DFUs, and there would need to be some 3" pipe.]

- On the shower trap arm, I'd be inclined to replace the combo with a wye that is farther towards the bottom of the picture, with a 45 at the appropriate point to the right of the current combo location. But if that complicates your platform framing too much, or raises your trap more than you'd like, what you show is fine.

- On the lav drain routing, I'd be inclined to minimize the distance up down the page from the upstream left-right lav drain segment to where the shower comes in. The tub can join the lav drain in a variety of ways as the lav drain run left right either above or below (on the page) the tub drain. The only constraint is that the lav drain shouldn't pass directly under the tub drain. Best I think would be to point the tub trap outlet at a 45 angle to the lav drain and run it directly into a wye on the lav drain.

Cheers, Wayne