Dave_in_Troy

New Member

- Messages

- 1

- Reaction score

- 0

- Points

- 0

Hi Guys,

I'm not a plumber so I hope you can give me some advice.

Right now I own a house that's about 75 years old, a 2 story center hall colonial. It currently has a convection flow steam system installed. I think the furnace is the original one. It's an old coal-fired monster and someone pulled out the coal grates and stuffed in an oil gun. I have 10 Aero steam/water radiators, each with one 1.25" feed/return pipe and a pressure relief valve.

My problem is that the oil bill to keep this dinosaur running is killing me, the upstairs is too hot, the downstairs is too cold, I don't think the old steam trunking system can be zoned and some of the cast iron fittings on the furnace itself are rusting. I think I need to put this thing out of my misery.

My overall plan is to rip out the entire existing system including the feeds to the radiators (but not the radiators themselves), the furnace and the oil tank. I want to bring in a natural gas line from the feeder line across the street and put in a new gas furnace.

I want to have 3 zones, one for upstairs, one downstairs and one for an indirect hot water tank.

For the distribution piping to the radiators I am thinking of running 1 PEX trunks and 3/4 PEX feed/returns to each radiator i.e. not home-running all the lines to a manifold. No trunk would support more than 3 radiators. Hopefully using PEX will allow me to avoid putting joints in the walls or ceilings and minimize the amount of sheetrock I have to hack up to get the piping in. Also, copper is crazy expensive these days and I am not a pro at sweating copper joints. I want to run ¾ PEX for better flow to the radiators (1/2 is too small once you account for the fittings I think).

I am thinking of using the Watts fittings and either the Watts SS cinch rings or the standard brass crimp rings (which is better?). Also, I would have to find a source for the oxygen-barrier PEX pipe (any good source?).

For the radiators themselves I have a bit of a problem. The side of the radiator that is currently hooked up to the steam system should be ok, I think I can break the union and reduce down to ¾ pex. The other end has been sealed with the factory plug since they were new and after 75 years of steam they WILL NOT move. The cast material the plug is made of won't hold enough pressure to break the rusted in seal, the metal just deforms. My plan is to drill through the face of the plug and tap it for 1 NTP, from there I can attach ¾ pex fitting. I tried this on a spare radiator that I removed last 1/2 it seems to work, although I haven't pressure tested it yet. Then I would have to drill and tap for the air bleeder valves and plug the hole where the steam pressure relief valve was attached.

I would have to pay someone to install the furnace unit itself along with the water heater tank, circulation pumps, expansion tank, connect to existing water lines, run the gas line and due any necessary system tuning. I would do all the plumbing for the trunk lines and up to the radiators (I just can't afford 85$/hour for that many hours).

OK, that's the plan. Please tell me what's wrong with it.

Thanks for your help.

David

I'm not a plumber so I hope you can give me some advice.

Right now I own a house that's about 75 years old, a 2 story center hall colonial. It currently has a convection flow steam system installed. I think the furnace is the original one. It's an old coal-fired monster and someone pulled out the coal grates and stuffed in an oil gun. I have 10 Aero steam/water radiators, each with one 1.25" feed/return pipe and a pressure relief valve.

My problem is that the oil bill to keep this dinosaur running is killing me, the upstairs is too hot, the downstairs is too cold, I don't think the old steam trunking system can be zoned and some of the cast iron fittings on the furnace itself are rusting. I think I need to put this thing out of my misery.

My overall plan is to rip out the entire existing system including the feeds to the radiators (but not the radiators themselves), the furnace and the oil tank. I want to bring in a natural gas line from the feeder line across the street and put in a new gas furnace.

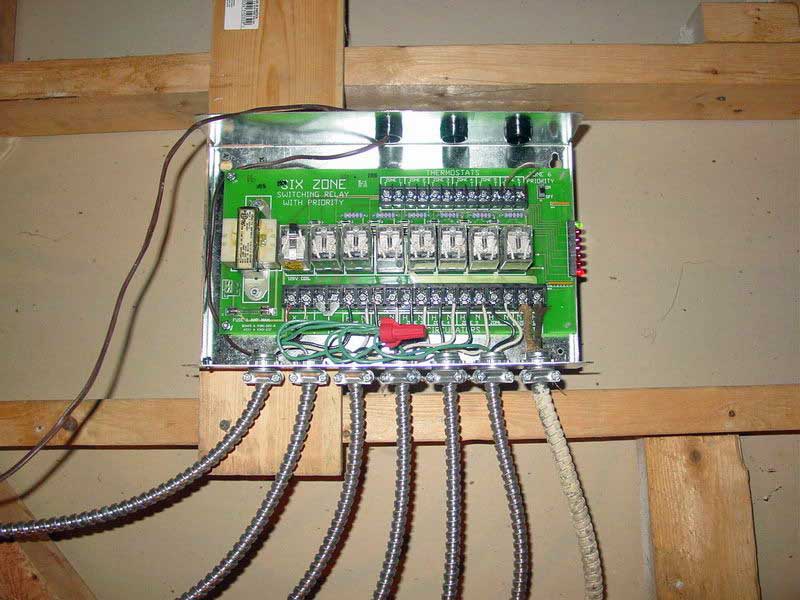

I want to have 3 zones, one for upstairs, one downstairs and one for an indirect hot water tank.

For the distribution piping to the radiators I am thinking of running 1 PEX trunks and 3/4 PEX feed/returns to each radiator i.e. not home-running all the lines to a manifold. No trunk would support more than 3 radiators. Hopefully using PEX will allow me to avoid putting joints in the walls or ceilings and minimize the amount of sheetrock I have to hack up to get the piping in. Also, copper is crazy expensive these days and I am not a pro at sweating copper joints. I want to run ¾ PEX for better flow to the radiators (1/2 is too small once you account for the fittings I think).

I am thinking of using the Watts fittings and either the Watts SS cinch rings or the standard brass crimp rings (which is better?). Also, I would have to find a source for the oxygen-barrier PEX pipe (any good source?).

For the radiators themselves I have a bit of a problem. The side of the radiator that is currently hooked up to the steam system should be ok, I think I can break the union and reduce down to ¾ pex. The other end has been sealed with the factory plug since they were new and after 75 years of steam they WILL NOT move. The cast material the plug is made of won't hold enough pressure to break the rusted in seal, the metal just deforms. My plan is to drill through the face of the plug and tap it for 1 NTP, from there I can attach ¾ pex fitting. I tried this on a spare radiator that I removed last 1/2 it seems to work, although I haven't pressure tested it yet. Then I would have to drill and tap for the air bleeder valves and plug the hole where the steam pressure relief valve was attached.

I would have to pay someone to install the furnace unit itself along with the water heater tank, circulation pumps, expansion tank, connect to existing water lines, run the gas line and due any necessary system tuning. I would do all the plumbing for the trunk lines and up to the radiators (I just can't afford 85$/hour for that many hours).

OK, that's the plan. Please tell me what's wrong with it.

Thanks for your help.

David

Last edited by a moderator: