Toddjb

New Member

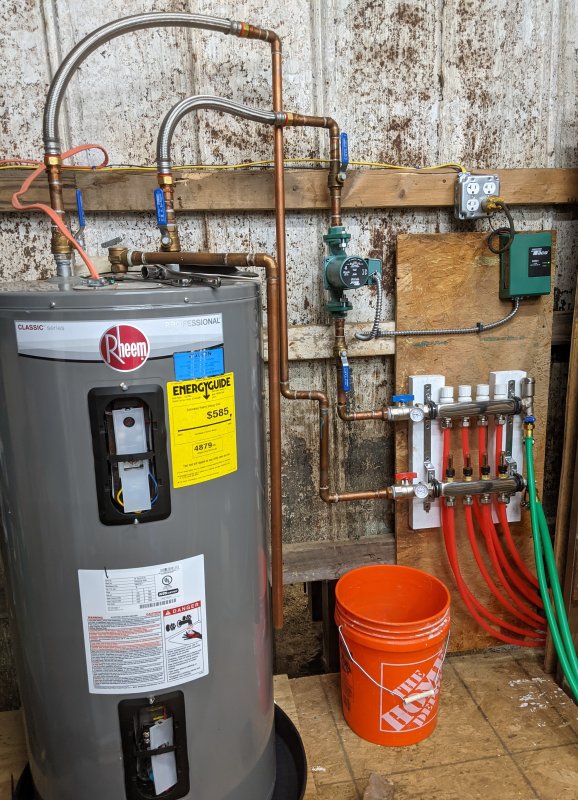

All, I just installed the radiant system in my shop.

All is working as intended, except when the system cycles off a cup or so worth water comes out the water heater discharge pipe.

Any ideas why this is happening? And how to fix it?

This is a completely closed loop system. I have the water heater set to 120 degrees.

All is working as intended, except when the system cycles off a cup or so worth water comes out the water heater discharge pipe.

Any ideas why this is happening? And how to fix it?

This is a completely closed loop system. I have the water heater set to 120 degrees.