Giantsean

Member

Hi All,

I've shared many a tale of woe from an ~2500 sf old mostly-masonry house renovation including a new central hydro heat/air system. I won't go rehash every detail but they should all still be available if interested.

Since then I've done a few useful and important things:

- Fixed all the backwards plumbing

- Had an energy audit and done a lot of my own air sealing as well (audit blower door test indicated ~1000cfm improvement), fixed duct leaks where I could find them

- Replaced the incorrect heat pump zone controller w/ a Honeywell HZ432, installed DATS in one supply trunk

- Rigged a relay w/ timer to address air handler blowing cold air during a DHW call

- Bought an Ecobee w/ multiple sensors to help balance the rooms

The above and other efforts have made a pretty significant difference. The house definitely stays warmer and holds temp much better. Not perfect, but at least now it's livable. The last big job I have is to try to optimize the 1st floor ductwork, and that raises some new questions.

Right now I have a 2 zone 1st floor due to the (at the time) huge variation in temps on different sides of the house (due to differences in insulation and air sealing). My 1F air handler (AS AAM7) hydro board is set up "wrong" ie it is set for max fan for an external (non-slide in) hydro coil. This is to allow sufficient CFM to hit the 2nd zone while both zones are calling for heat. No matter what, I plan to seal the ductwork better (it was not sealed by installers) and replace flex with metal duct. That said, I am not sure that will fully solve the problem of enough pressure across the system. Now that I have the DATS installed, I can also see that temps increase quite a bit from the usual 105 to higher when the fan is set to a slower speed. So I have a few ideas:

- Set the fan to the proper speed and Install a booster for zone 2 DOWNSTREAM of the coil to help the air get to the end of the house

- Now that there is less difference between zone 1 and 2, do away with the 2nd zone completely and lose the remainder of the zone 1 trunk, run the branches into the zone 2 trunk (keeping the plenum the same

- I have also been told the ducting is wrong as some branches run straight off the end of the trunk (I forgot the term for the extra amount of run that allows pressure to build) so either way that can be fixed.

- Also wondering if I need more returns in general where I can (there are some logistical barriers), as they are all located toward one side of the house, all on the 2nd zone. I know you aren't supposed to have returns in a kitchen, but I'm wondering if I stick to the "dining" end of the kitchen, keeping 10ft away from exhaust fans, it wouldn't be a bad addition.

- Speaking of the kitchen, it is probably the coldest area overall. Wondering if some more supplies would also help.

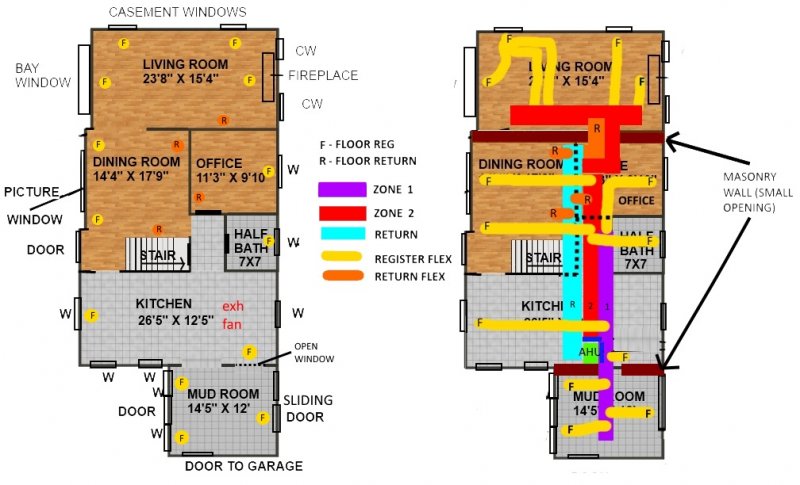

I know there is a lot of calculation involved w/ any ductwork, but my installers weren't the calculating type, so I would consider shining the turd w/o having to re-sh*t it a big win . I've attached a duct map to help illustrate my setup... the left is the floorplan/register layout and the right the ducts in the cellar overlaid. Sorry for writing a huge book but this effort has become somewhat of an obsession for me... I'm going to beat this house into submission one way or the other

I've shared many a tale of woe from an ~2500 sf old mostly-masonry house renovation including a new central hydro heat/air system. I won't go rehash every detail but they should all still be available if interested.

Since then I've done a few useful and important things:

- Fixed all the backwards plumbing

- Had an energy audit and done a lot of my own air sealing as well (audit blower door test indicated ~1000cfm improvement), fixed duct leaks where I could find them

- Replaced the incorrect heat pump zone controller w/ a Honeywell HZ432, installed DATS in one supply trunk

- Rigged a relay w/ timer to address air handler blowing cold air during a DHW call

- Bought an Ecobee w/ multiple sensors to help balance the rooms

The above and other efforts have made a pretty significant difference. The house definitely stays warmer and holds temp much better. Not perfect, but at least now it's livable. The last big job I have is to try to optimize the 1st floor ductwork, and that raises some new questions.

Right now I have a 2 zone 1st floor due to the (at the time) huge variation in temps on different sides of the house (due to differences in insulation and air sealing). My 1F air handler (AS AAM7) hydro board is set up "wrong" ie it is set for max fan for an external (non-slide in) hydro coil. This is to allow sufficient CFM to hit the 2nd zone while both zones are calling for heat. No matter what, I plan to seal the ductwork better (it was not sealed by installers) and replace flex with metal duct. That said, I am not sure that will fully solve the problem of enough pressure across the system. Now that I have the DATS installed, I can also see that temps increase quite a bit from the usual 105 to higher when the fan is set to a slower speed. So I have a few ideas:

- Set the fan to the proper speed and Install a booster for zone 2 DOWNSTREAM of the coil to help the air get to the end of the house

- Now that there is less difference between zone 1 and 2, do away with the 2nd zone completely and lose the remainder of the zone 1 trunk, run the branches into the zone 2 trunk (keeping the plenum the same

- I have also been told the ducting is wrong as some branches run straight off the end of the trunk (I forgot the term for the extra amount of run that allows pressure to build) so either way that can be fixed.

- Also wondering if I need more returns in general where I can (there are some logistical barriers), as they are all located toward one side of the house, all on the 2nd zone. I know you aren't supposed to have returns in a kitchen, but I'm wondering if I stick to the "dining" end of the kitchen, keeping 10ft away from exhaust fans, it wouldn't be a bad addition.

- Speaking of the kitchen, it is probably the coldest area overall. Wondering if some more supplies would also help.

I know there is a lot of calculation involved w/ any ductwork, but my installers weren't the calculating type, so I would consider shining the turd w/o having to re-sh*t it a big win . I've attached a duct map to help illustrate my setup... the left is the floorplan/register layout and the right the ducts in the cellar overlaid. Sorry for writing a huge book but this effort has become somewhat of an obsession for me... I'm going to beat this house into submission one way or the other