This is a rental built in the 60's. I'm having a guy do some joist work and put in a new floor, and I decided to get a new vanity and address the old shower/toilet pipes at the same time.

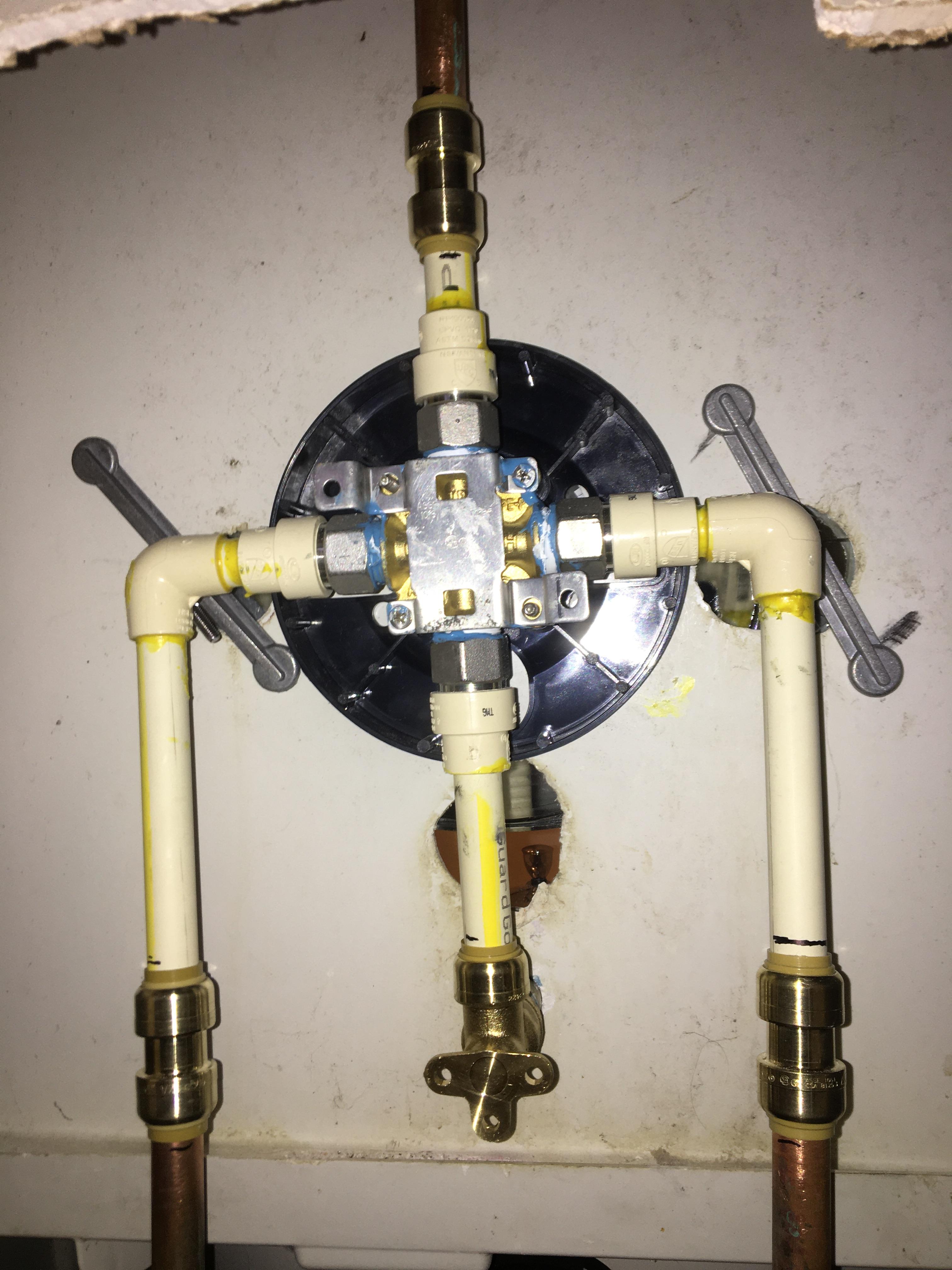

The threads where the bonnet nuts go on the tub handles have stripped out smooth on one side, and I've been having to replace cartridges about every 4 or 5 months from leaks. I'm assuming stripped threads pretty much means the whole shower valve needs replaced?

I've done a lot of plumbing DIY, but have never messed with a shower valve, and I just use sharkbites on supply lines. Can I use sharkbites for a shower valve replace? I would probably put in an access panel, so I would have easy access to it for future issues/observations.

If this is something that's feasible, can anyone recommend aa shower valve -- either a specific model, or the general name of the type of valve -- that would be a good replacement? Just want something basic and inexpensive, and like I said, I've never dealt with shower valves before, so I dont know the lingo.

Thanks for any input.

(If I had time, I would learn to solder, but I have a very short window to replace this, so I would prefer to use sharkbites right now.)

The threads where the bonnet nuts go on the tub handles have stripped out smooth on one side, and I've been having to replace cartridges about every 4 or 5 months from leaks. I'm assuming stripped threads pretty much means the whole shower valve needs replaced?

I've done a lot of plumbing DIY, but have never messed with a shower valve, and I just use sharkbites on supply lines. Can I use sharkbites for a shower valve replace? I would probably put in an access panel, so I would have easy access to it for future issues/observations.

If this is something that's feasible, can anyone recommend aa shower valve -- either a specific model, or the general name of the type of valve -- that would be a good replacement? Just want something basic and inexpensive, and like I said, I've never dealt with shower valves before, so I dont know the lingo.

Thanks for any input.

(If I had time, I would learn to solder, but I have a very short window to replace this, so I would prefer to use sharkbites right now.)