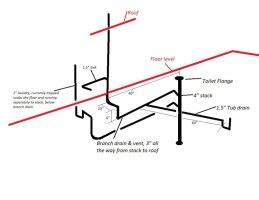

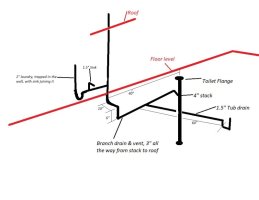

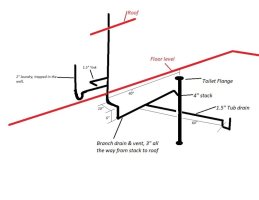

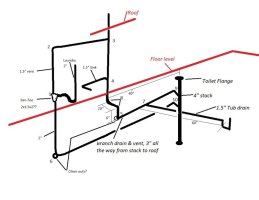

Hi all, I am replumbing my small main bathroom and replaceing the cast iron and steel DWV pipes. I have been trying to understand wet venting

requirements (among other requirements) to plan this out. But I am somewhat confused, so I thought I would turn to the folks at Terry Love forum for help. I basically want help designing the whole system. 1 Sink, 1 water closet (toilet), 1 tub/shower, 1 laundry drain. My current setup I believe everything is wet vented accept the sink. The laundry setup is wrong, but not sure what to do with that because of the implications for the wet vented tub, if any.

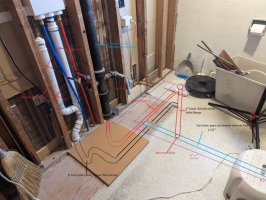

I have complete access below in a full basement. This is 1 story ranch from 1960's. I have included some measurements in the picture.

Also, the sink drain needs to be moved to the left of the vertical branch drain, over to the where the pex is at.

Can you please help me design this so I don't mess it up? Thanks.

Note: I will be putting in a new tub drain/overflow when I do this.

requirements (among other requirements) to plan this out. But I am somewhat confused, so I thought I would turn to the folks at Terry Love forum for help. I basically want help designing the whole system. 1 Sink, 1 water closet (toilet), 1 tub/shower, 1 laundry drain. My current setup I believe everything is wet vented accept the sink. The laundry setup is wrong, but not sure what to do with that because of the implications for the wet vented tub, if any.

I have complete access below in a full basement. This is 1 story ranch from 1960's. I have included some measurements in the picture.

Also, the sink drain needs to be moved to the left of the vertical branch drain, over to the where the pex is at.

Can you please help me design this so I don't mess it up? Thanks.

Note: I will be putting in a new tub drain/overflow when I do this.

Attachments

Last edited: