Hello all,

I installed a dehumidifier that drains through a 3/4" vinyl tube that goes into my air handler closet where there is an existing PVC condensate line.

I have attached a photo of what is currently there. As you can see, the existing PVC condensate line has a threaded plug that removes for cleaning out the condensate line. What is the best fitting (or combination of fittings) to attach the 3/4" vinyl tube to the 3/4" PVC that is easily removable so that I can continue to flush and clean the condensate line?

I'd prefer not to reduce the ID of the 3/4" vinyl tubing (so that it is large enough to stay free from clogging up), so here are two ideas I came up with:

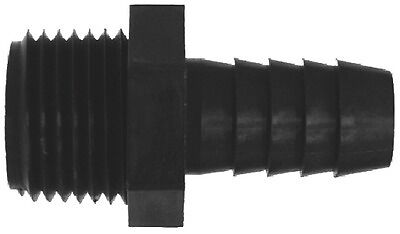

Maybe I could use this compression fitting alone (but maybe it would first require reducing the end of the vinyl tube to PVC via a barbed fitting):

I was also thinking of using a 3/4" threaded fitting to add a short length of 1" PVC that the vinyl tubing could rest inside:

Thanks for reading!

I installed a dehumidifier that drains through a 3/4" vinyl tube that goes into my air handler closet where there is an existing PVC condensate line.

I have attached a photo of what is currently there. As you can see, the existing PVC condensate line has a threaded plug that removes for cleaning out the condensate line. What is the best fitting (or combination of fittings) to attach the 3/4" vinyl tube to the 3/4" PVC that is easily removable so that I can continue to flush and clean the condensate line?

I'd prefer not to reduce the ID of the 3/4" vinyl tubing (so that it is large enough to stay free from clogging up), so here are two ideas I came up with:

Maybe I could use this compression fitting alone (but maybe it would first require reducing the end of the vinyl tube to PVC via a barbed fitting):

I was also thinking of using a 3/4" threaded fitting to add a short length of 1" PVC that the vinyl tubing could rest inside:

Thanks for reading!