Well, it would take a long time to explain water hammer. But here is a good place to start.

en.wikipedia.org

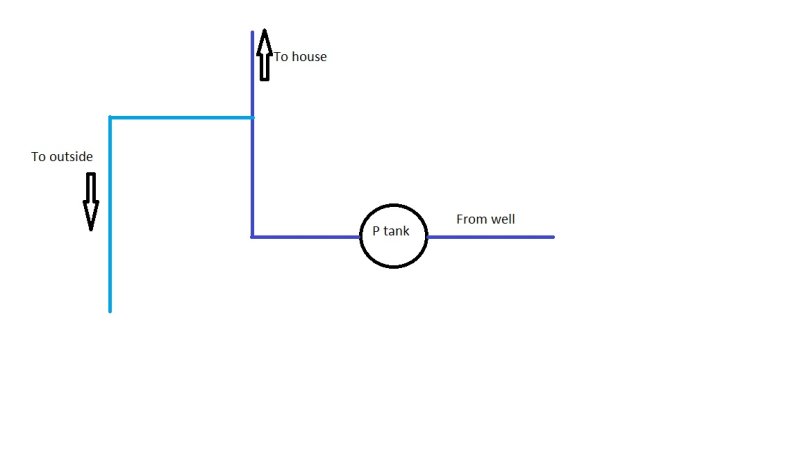

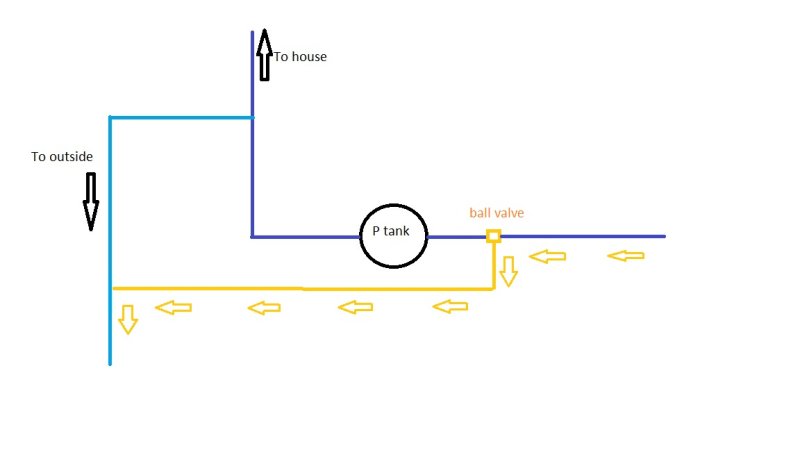

And why would you need a pressure tank to "absorb" water hammer, if there wasn't any water hammer to begin with? Actually, a bladder/diaphragm style pressure tank doesn't do much to absorb water hammer. These tanks are teed onto the mainline, where water hammer flies by at 3,000-8,000 feet per second. The shock wave won't make the right turn to go into the tank. The only thing that really absorbs water hammer is the elasticity of the pipe and friction loss. Softer pipe like poly will swell and absorb some of the pulse. But it only subsides once it has bounced back and forth throughout the entire plumbing system several times. As the shock wave travels back and forth in the piping system, the friction loss finally brings it to a halt. So, the pipe and plumbing always sees the water hammer, even if you don't. It just happens so fast you don't see it. But yes, water hammer causes way more pressure on the system than the pump can even build.

I know some of the things I say sound outrages, but that doesn't make them any less true. I know some of the things I claim sound too good to be true. I thought the same way for a long time. I finally realized the CSV is too good to be true. That is why the pump companies hate me, not because there is anything wrong with the CSV.

There is really no flow rate you can run for any length of time, long or short that can damage your pump when using a CSV. The CSV really does eliminate water hammer and all the destruction that goes with. The CSV really does make pumps last longer and able to use much smaller pressure tanks. Strong constant pressure to the house is just another beneficial side effect of the CSV. Over thirty years ago we thought all it did was stop a pump from cycling on and off, which is why we called it a Cycle Stop Valve. We had no idea it would cause such a problem in the industry that they would spend billons trying to make something that works as well as the CSV, that doesn't shoot their planned obsolescence in the foot.

Pump manufacturers would not have blacklisted the CSV as a disruptive product all those years ago if it would not have been bad for their business. But making pumps last longer and use smaller pressure tanks is not a good thing if you make pumps and tanks.

I don't preach planned obsolescence because I make so much money selling Cycle Stop Valves. I preach about what I have learned because I am angry. I spent over 25 years going to every pump school and factory training day I could find to learn which pumps are best and what is the best way to install them. This factory will tell you their "tri-seal" design is superior because of blah, blah, blah. The next factory will say their Stainless Steel impellers are superior to everyone else's plastic designs, and so on, and so on, and so on. But when offered a real and simple solution to nearly every problem associated with a pump system, they wanted nothing to do with it. After testing Cycle Stop Valves in their own test facilities, people I had done business with for decades would no longer look me in the eyes. It took me several more years to find out they were told the Cycle Stop Valve makes pumps last longer, use smaller pressure tanks, and anyone associated with their company would be terminated immediately for even mentioning one.

Not only was I pissed when I finally discovered what was going on, but my eyes were open to planned obsolescence in everything around me. So, I preach for people to not be sheep and just do what the pump companies says to do. They will spend millions on advertising and hours talking you into something that cost a lot and doesn't last very long, as that is how they make money. They will lie to you about things that make your pump last longer, as that goes against their pocketbook. I was never a conspiracy theorist before. But the pump industry has done such a good job for so long keeping people from knowing the best way to control pumps, that I now have serious doubts about anything else I see a flashy add or government mandate about.

Oh and BTW, I am pretty much retired these days, which is why I have time to do this. So, I am not out to make big bucks talking people into inexpensive CSV's, but rather am trying to give the benefit of my many years of experience.