If you go the reverse-indirect route with a mod-con in order to micro-zone it you end up limiting your condensing efficiency somewhat in exchange for a high minimum burn. If your smallest zone has over 100' of fin-tube you'd be better off with a standard indirect running as a priority zone, since it would give you more hot water and a few percent better AFUE on the space heating. As long as the radiation of the smallest zone can deliver ALL of the heat of the mod-con's lowest fire the flow and reset curve can be set up to run in condensing mode most of the time, and won't need buffering to keep from short-cycling. A 100' loop of typical fin-tube typically delivers ~20KBTU/hr @ 120F average water temp, which means the return water will be in the 110-115F range, with boiler output in the 125-135F range, depending on how it's set up .

The min-mod of the smallest Alpine or Solo are well under 20K, so this is totally possible. Only if you micro-zoned it with a really stubby zone would you absolutely need to buffer it. If I understand it correctly your smallest zone is 57', which would deliver ~11.5K at 120F average water temp, and ~14K @ 130F average water temp. The min-mod input of both the Alpine 80 and Solo 60 is 16K, so at 90% efficiency it's output right in there with the 130F average water temp number- you can almost certainly tweak the flow & delta-T to get it to run mid-mod at temps under 130F without short-cycling (or buffering), and almost always be running better than 90% efficiency. If there's room to add length (or cast-iron baseboard) to the radiation in the coolest rooms you can most likely get it to run 125F or lower much of the time without having to add mass. (I'm a fan of replacing fin-tube with recycled cast-iron when you can get it cheap, since the output is better at low temp and FEELS better, and is

fully specified down to 100F, where it's still putting out 125BTU/foot, a temp where fin-tube just doesn't operate reliably. It's over $40/foot new, but can be had for half that or less scrounging on Craigslist or scrapyards. Weil McLain's cast baseboard specs are nearly identical. If you lenthen or replace radiation, consider it, especially for rooms where you actually hang out.)

You won't necessarily need to go with a hydraulic seperator on a system your size either, but if you go that route, using the smallest Ergomax (~$1.2K) as both the hydraulic seperator adds over 25gallons of thermal mass to the heating system, and uses as pre-heat to a small indirect would mean that most of your water heating BTUs could also be had in fully condensing mode (during the heating season, anyway.) Otherwise, fabricating a low-mass hydraulic seperator out of copper fittings & pipe isn't rocket science. But I'm thinking your zones are big enough yet low-head enough that this could be done with a single pump + zone valves.''

BTW: The ASHRAE 99% design temp for Philly is 10F, the 97.5% design temp is 14F. Yes, it sometimes gets colder than that as an absolute low, but it never STAYS colder than that long enough to matter. The 99% design temp is based on binned hourly weather data over 25 heating seasons- fewer than 1% of the hours in a heating season will be lower than that number. If you're designing to 0F in Philly you're starting out with an 18% oversized assumption, (then typically adding onto that for some margin.).

If you run deep setbacks AND run outdoor reset, your recovery times are long unless you bump up the temp on the reset curve. With a condensing burner it's almost always a net-negative to do that. Even with 140F average water temp you're getting some condensing, hitting around 89-90%, and getting ~300BTU/foot out of your baseboard. You may NEVER have to exceed 140F on your system in Philly if you tweak the curves optimally. (Depends on the heat loss & baseboard length on your worst-case room, and how critical the temp in that room is.)

You can't reliably place an EF number on an indirect, since it depends a lot on the installation, and the BTU rating, combustion efficiency and mass of the boiler. With a tiny mod-con driving it and you insulate all the plumbing it'll be over 0.80, even in summer. If the indirect is set up to a low enough temp with a decent hysteresis a mod-con might hit the high-80s or even 0.90 EF in water-heating only mode. With a mid-sized cast-iron beastie behind it it'll be pretty close to the AFUE of the boiler if the boiler is less than 2x oversized for the peak load, but in summer the mass and standby loss of the boiler can take it below 0.40. On an annualize average it's still an efficiency improvement compared to a separate tank-heater + boiler though.

With 40' of 3/4" pipe you're abandoning about a gallon of hot water at the end of a draw. If you insulated those pipes with 3/4" walled pipe insulation (not the 3/8" stuff availabe at box stores), it's not a complete loss- you'll still have usably-hot water even 20-30minutes later. If it's faster hot-water response you're after, you could arguably install the boiler & indirect where you're proposing to put the tank, since a wall-hung mod-con is easily side vented, and takes little space. You may have to reconfigure the heating loops a bit to minimize the run-lengths of heating system plumbing in unconditioned space. From an overall cost and efficiency point of view I can't imagine goint with a separate tank would be the right thing in most situtations.

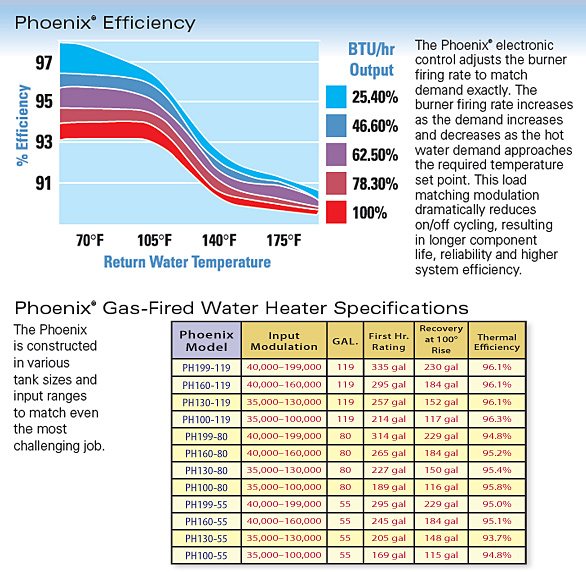

You might want to price out what a 55 gallon smallest-burner

Phoenix would run you. You can run similar efficiencies as a mod-con + indirect with one of these, and it's inherently self-buffered. They're dead-simple to design around, and has plenty of burner for your needs- your design-day heat load is about min-mod on the thing, and it'll automatically run min-mod all the time except during heavy hot-water usage. I'll bet you can hit 93% without doing the math on the heating system design, just setting it to 125-130F and bumping it up 5F at a time only if it doesn't keep up in the coldest room. Without low-temp radiation, only baseboard you'd never hit 96% in your wildest dreams anyway.

Uh, sorry, I meant the

Pioneer, (basically a Phoenix with a space-heating heat exchanger.)