I have another Basement Bathroom inquiry for this forum. My wife and I have started on a Basement renovation which includes the addition of a full bath and Laundry room. Our Basement did not have any DWV roughed in when it was built 17 years ago. Unfortunately the Waste line leaving the house is above the slab of the basement floor requiring an ejector pump.

Since we have been planning this for a number of years, I have already purchased some of the needed fixtures to complete this installation. I have the sewage ejector basin and 1/2hp Flotec pump. Now I am ready to get this installed into the floor, but wanted to make sure that I have everything figured out before I begin cutting the floor.

Our main concern is the vent for the Basin. In the basement I don't have access to any vent lines. What I do have access to is a 1.5†Vent in an upstairs wall that is currently being used for the drain on the washing machine. Once the Laundry room is moved down to the basement, that drain and vent will not be used any longer. The drain ran directly from the Washing machine to the 3" drain leading out of the house. This 1.5" drain is the last connection on the 3†drain before it leaves the house. There is nothing below it. What I would like to be able to do is cap the drain line and use the vent for the dedicated Ejector Vent. I know that it is suppose to be 2â€, but there is nothing available. Since this vent is connected to nothing else until it reaches the 3†stack at the roof, would it work? I know that it won't pass code, BUT..

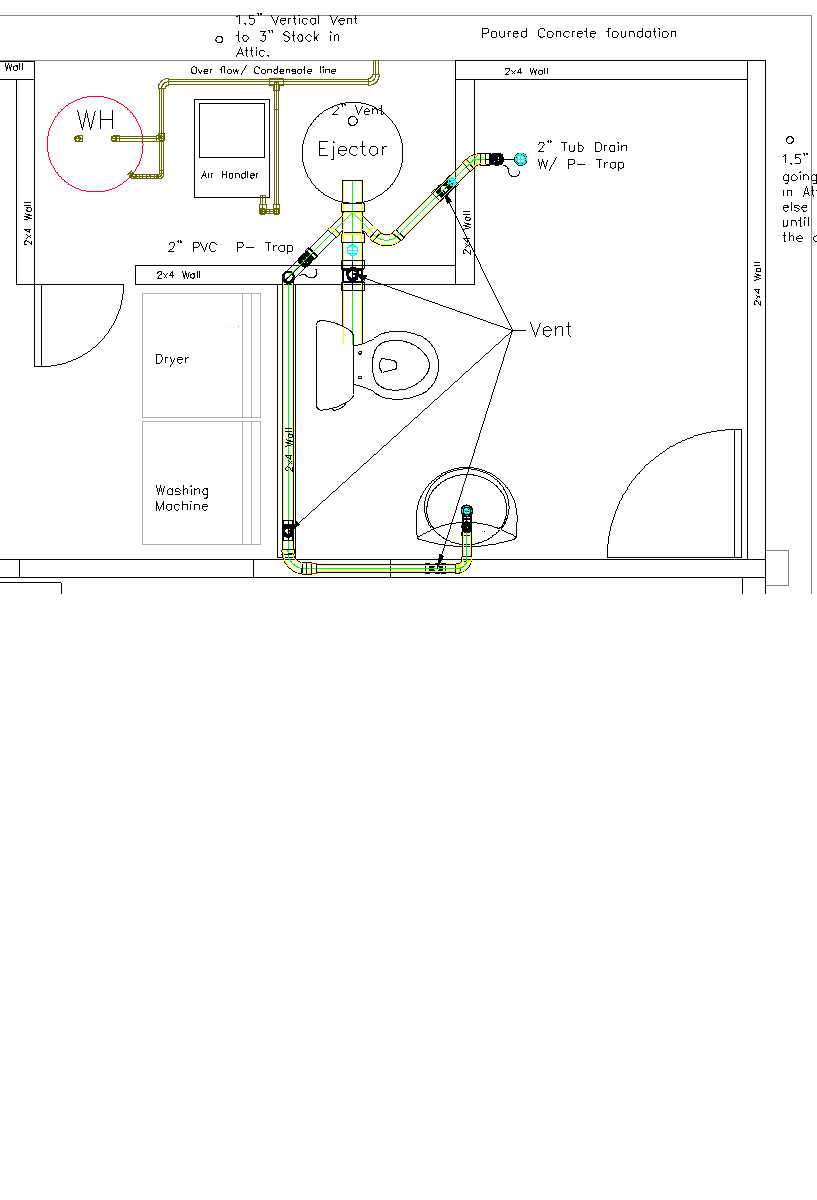

I have attached an Image of what I plan on doing. This image is to scale. I need some help with my drain line and fittings as far as what is allowed, and what isn't. I don't have any experience with the plumbing code and any help would be greatly appreciated.

Steve Vincent

Since we have been planning this for a number of years, I have already purchased some of the needed fixtures to complete this installation. I have the sewage ejector basin and 1/2hp Flotec pump. Now I am ready to get this installed into the floor, but wanted to make sure that I have everything figured out before I begin cutting the floor.

Our main concern is the vent for the Basin. In the basement I don't have access to any vent lines. What I do have access to is a 1.5†Vent in an upstairs wall that is currently being used for the drain on the washing machine. Once the Laundry room is moved down to the basement, that drain and vent will not be used any longer. The drain ran directly from the Washing machine to the 3" drain leading out of the house. This 1.5" drain is the last connection on the 3†drain before it leaves the house. There is nothing below it. What I would like to be able to do is cap the drain line and use the vent for the dedicated Ejector Vent. I know that it is suppose to be 2â€, but there is nothing available. Since this vent is connected to nothing else until it reaches the 3†stack at the roof, would it work? I know that it won't pass code, BUT..

I have attached an Image of what I plan on doing. This image is to scale. I need some help with my drain line and fittings as far as what is allowed, and what isn't. I don't have any experience with the plumbing code and any help would be greatly appreciated.

Steve Vincent

Last edited by a moderator: